Sample Preparation Basics

Sample Processing

In Transmission Electron Microscopy (TEM) sample preparation, the initial steps of processing are crucial for achieving high-quality results. The process begins with cleaning, which involves removing any surface impurities. This is typically done using deionized water, which is effective for most materials, or solvents such as alcohol or acetone, which are particularly useful for organic substances. The choice of cleaning agent depends on the sample's composition and the nature of the impurities present.

Following cleaning, the sample undergoes grinding. This step is tailored to the hardness of the material. For hard materials, tools such as alumina sandpaper or silicon carbide balls are employed. These tools are selected based on their ability to effectively reduce the sample's thickness without causing excessive damage. For softer materials, alternative methods such as cell crushing fluids may be used, ensuring that the grinding process is both effective and gentle.

The final step in the processing sequence is polishing. This ensures that the sample surface is smooth and free from scratches or other imperfections. Polishing is conducted with controlled speed and pressure, using specialized equipment designed to maintain uniformity across the sample. This meticulous process is essential for obtaining clear and detailed TEM images, as any surface irregularities can obscure the underlying structure.

In summary, the sequence of cleaning, grinding, and polishing is meticulously planned and executed to ensure that the sample is prepared to the highest standards for TEM analysis. Each step is tailored to the specific characteristics of the sample, ensuring optimal results.

Sample Fixation

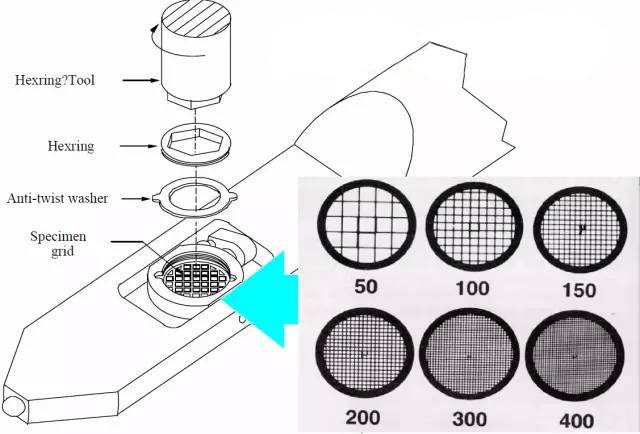

To obtain clear Transmission Electron Microscopy (TEM) images, precise sample fixation is essential. The fixation process ensures that the sample remains stable and intact during the imaging process, thereby enhancing the quality of the resultant images. Various methods are employed depending on the nature and size of the sample:

-

Clamping: This method is ideal for flaky or granular samples. By securely clamping these samples, they are prevented from moving or disintegrating under the electron beam, which is crucial for maintaining image clarity.

-

Encapsulation: Biological samples or tiny particles benefit from encapsulation. This technique involves enclosing the sample in a protective material, such as a resin, which not only stabilizes the sample but also shields it from environmental contaminants and electron beam damage.

-

Direct Attachment: For thin sheets or particles, direct attachment is the preferred method. This involves affixing the sample directly to the TEM grid using adhesives or other bonding agents. This method ensures that the sample remains in a fixed position, facilitating precise imaging.

Each of these methods plays a critical role in ensuring that the sample is properly prepared for TEM imaging, thereby contributing to the overall quality and reliability of the scientific data obtained.

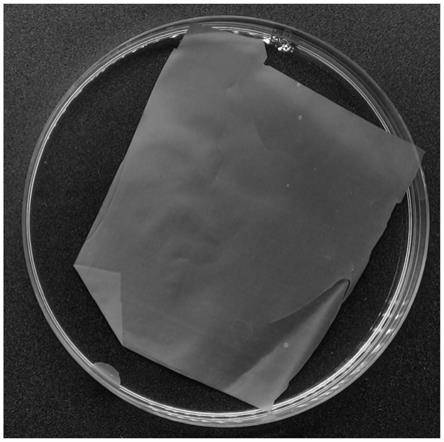

Sample Covering

Protecting the sample from environmental and light damage is crucial for obtaining high-quality TEM images. This process involves the application of specialized covering agents tailored to the specific needs of the sample. For instance, aluminum oxide is often employed to shield the sample from UV radiation and electron beam damage, ensuring that the sample remains intact during the imaging process. Similarly, magnesium fluoride is used to prevent chemical erosion, which can degrade the sample over time.

For biological samples, the use of biologically active films is particularly important. These films not only protect the sample from external contaminants but also maintain the structural integrity of the biological material, allowing for detailed and accurate imaging. The selection of the appropriate covering agent depends on the nature of the sample and the specific challenges it faces during the TEM imaging process.

| Covering Agent | Application | Benefits |

|---|---|---|

| Aluminum Oxide | UV and Electron Beam Protection | Ensures sample integrity under high-energy radiation |

| Magnesium Fluoride | Chemical Erosion Prevention | Prevents degradation due to chemical interactions |

| Biologically Active Films | Protection for Biological Samples | Maintains structural integrity and protects against external contaminants |

By carefully choosing and applying the right covering agents, researchers can significantly enhance the quality and longevity of their TEM samples, facilitating more accurate and detailed analyses.

Practical Tips

Selecting Grinding Tools

When selecting grinding tools for Transmission Electron Microscopy (TEM) sample preparation, it is crucial to consider both the nature and shape of the sample. For hard materials, tools such as alumina sandpaper or silicon carbide balls are ideal due to their abrasive properties, which effectively grind down the material without causing undue damage. These tools are designed to handle the high resistance of hard materials, ensuring that the sample maintains its structural integrity throughout the grinding process.

In contrast, soft materials require a different approach to avoid excessive damage. Here, cell crushing fluid can be employed to gently break down the material while maintaining control over the grinding process. This fluid helps in managing the time and strength applied, thereby preventing any potential harm to the delicate structure of soft samples. By carefully regulating the grinding parameters, the risk of sample damage is minimized, ensuring that the final TEM images are clear and precise.

The choice of grinding tools is not only influenced by material hardness but also by the specific requirements of the sample shape. For instance, flat samples might benefit from sandpaper, while more intricate shapes may necessitate the use of balls or other specialized tools. This adaptability ensures that each sample receives the most appropriate treatment, leading to better overall results in the TEM analysis.

Ensuring Sample Fixation

To achieve clear and detailed Transmission Electron Microscopy (TEM) images, it is crucial to ensure that samples are fixed accurately and stably. The fixation method largely depends on the nature and size of the sample. For instance, thin or granular samples often require clamping to maintain their position during the imaging process. This method involves using specialized holders that securely grip the sample, preventing any movement that could blur the image.

In contrast, biological or tiny particles necessitate a more delicate approach. Encapsulation is typically used for these types of samples. This technique involves embedding the particles in a protective medium, such as a resin or a gel, which not only stabilizes the sample but also shields it from environmental damage. The encapsulation process is particularly important for preserving the integrity of biological samples, ensuring that their structural details remain intact for high-resolution imaging.

For thin sheets or particles that are more robust, direct attachment is a viable option. This method involves adhering the sample directly to the TEM grid using a conductive adhesive. Direct attachment is advantageous for its simplicity and effectiveness in maintaining the sample's position without the need for additional support structures.

| Sample Type | Fixation Method | Description |

|---|---|---|

| Thin or Granular Samples | Clamping | Use specialized holders to securely grip the sample, preventing movement. |

| Biological or Tiny Particles | Encapsulation | Embed particles in a protective medium to stabilize and shield from damage. |

| Thin Sheets or Particles | Direct Attachment | Adhere sample directly to TEM grid using conductive adhesive for simplicity. |

Choosing the right fixation method is essential for obtaining high-quality TEM images. Each technique has its own set of advantages and is tailored to specific sample characteristics, ensuring that the sample remains stable and undamaged throughout the imaging process.

Choosing Covering Agents

When preparing samples for Transmission Electron Microscopy (TEM), selecting the appropriate covering agents is crucial for preserving sample integrity and enhancing image quality. Covering agents serve multiple purposes, including protecting the sample from environmental damage, preventing chemical erosion, and shielding against UV and electron beam exposure.

Types of Covering Agents

-

Aluminum Oxide (Al₂O₃): Ideal for UV and electron beam protection, aluminum oxide provides a robust barrier against high-energy radiation, ensuring that the sample remains intact during prolonged exposure to the electron beam.

-

Magnesium Fluoride (MgF₂): This covering agent is particularly effective in preventing chemical erosion. Magnesium fluoride forms a stable, protective layer that resists chemical interactions, which is essential for maintaining the structural integrity of the sample.

-

Biologically Active Films: For biological samples, biologically active films offer a specialized covering that not only protects the sample from environmental factors but also supports the biological activity of the specimen, ensuring that the sample remains viable for observation.

Benefits of Using Covering Agents

-

Enhanced Image Quality: By protecting the sample from degradation, covering agents help maintain the sample's original structure and composition, leading to clearer and more accurate TEM images.

-

Extended Sample Life: The protective layers provided by covering agents significantly extend the lifespan of the sample, allowing for multiple observations over an extended period without significant degradation.

-

Environmental Protection: Covering agents shield the sample from atmospheric contaminants and light exposure, which can otherwise cause significant damage to the sample's surface and internal structure.

In summary, the judicious selection and application of covering agents are essential steps in TEM sample preparation, ensuring that the sample remains intact and viable for high-resolution imaging.

Related Products

- Electrode Polishing Material for Electrochemical Experiments

- Electrode Fixture for Electrochemical Experiments

- MgF2 Magnesium Fluoride Crystal Substrate Window for Optical Applications

- Sample Support Body for Electrochemical Tests

- Optical Window Glass Substrate Wafer CaF2 Substrate Window Lens

Related Articles

- Understanding Electrodeposition with Electrochemical Electrodes

- Electrochemical Consumables: A Comprehensive Guide to Materials, Applications, and Selection

- How to Choose the Right Electrochemical Electrode

- Electrochemical Electrodes in Chemical Analysis

- Advanced Techniques in Coating Evaluation Using Electrolytic Cells