Shaking and mixing equipment

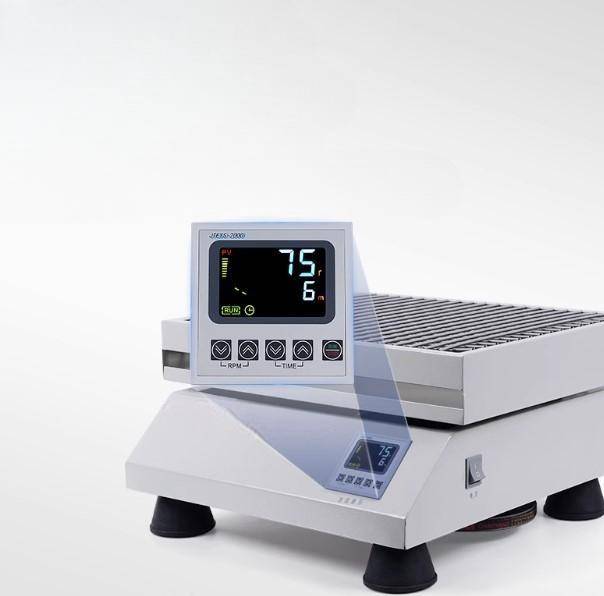

Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

Item Number : KTL-3

Price varies based on specs and customizations

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

The laboratory multifunctional small speed-regulating oscillator is a constant-speed experimental equipment specially developed for modern bioengineering production units. The equipment has a complete range of models and styles, and the large-capacity model has a large bottling volume. It is particularly suitable for pilot and small-batch production. It is an indispensable laboratory equipment for precision cultivation in scientific research, education and production departments such as plants, biology, microorganisms, genetics, viruses, environmental protection, and medicine.

Detail & Parts

Technical Parameters

| Model | KTL-3A | KTL-4A | KTL-5A | KTL-6A | KTL-8A |

|---|---|---|---|---|---|

| Display mode | LED display | LED display | LED display | LED display | LED display |

| Speed range | 40~300rpm | 40~300rpm | 40~300rpm | 40~300rpm | 40~300rpm |

| Timing range | 1~9999min | 1~9999min | 1~9999min | 1~9999min | 1~9999min |

| Standard configuration of pallet | universal spring clamp | universal spring clamp | universal spring clamp | upper clamp, lower spring clamp | universal spring clamp |

| Oscillation model | reciprocating | reciprocating | rotating | rotating | rotating |

| Oscillation amplitude | 20mm | 20mm | 20mm | 20mm | 20mm |

| Pallet working size | 520*300mm | 440*270mm | 440*350mm | 610*460mm (double layer) | 700*620mm |

| Weight | 17.3Kg | 13.5Kg | 20Kg | 65Kg | 65Kg |

Features

- LCD screen display, intuitive and clear display of operating status.

- Adopt DC motor, stable operation, low noise, and stepless adjustable oscillation speed.

- Adopt stainless steel spring clamp, which can be stretched and suitable for containers of different capacities.

- Can be adapted to a variety of reagent bottles to meet the needs of different customers.

- The outer shell is made of steel plate electrostatic spraying, with good anti-corrosion performance.

- Rubber non-slip foot pad, stable and firm without shaking.

- Slow start, stable speed control.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

4.7 / 5

Exceptional value for money. The shaker delivers precise results and is built to last.

4.8 / 5

Top-notch quality. The adjustable speed feature makes it versatile for various lab needs.

4.9 / 5

This shaker is a game-changer. Fast delivery and incredibly durable.

4.7 / 5

Impressive technological advancement. The LCD screen is a great addition.

4.8 / 5

Excellent build quality. The shaker handles heavy use with ease.

4.9 / 5

Highly recommend. The speed adjustment is perfect for our lab experiments.

4.7 / 5

Great value. The shaker’s precision and durability are outstanding.

4.8 / 5

Superb product. The adjustable speed and timer are very useful.

4.9 / 5

Fantastic shaker. Fast delivery and excellent customer service.

4.7 / 5

High-quality and reliable. The shaker’s performance is consistent.

4.8 / 5

Very satisfied. The shaker’s durability and precision are top-notch.

4.9 / 5

Excellent product. The adjustable speed feature is a great asset.

4.7 / 5

Great value for money. The shaker’s performance is impressive.

4.8 / 5

Highly durable. The shaker handles our lab’s needs perfectly.

4.9 / 5

Fantastic shaker. The adjustable speed and timer are very useful.

4.7 / 5

Excellent build quality. The shaker’s performance is consistent.

4.8 / 5

Great product. The shaker’s precision and durability are outstanding.

4.9 / 5

Highly recommend. The shaker’s adjustable speed is perfect for our lab.

4.7 / 5

Fantastic value. The shaker’s performance and durability are top-notch.

4.8 / 5

Excellent shaker. The adjustable speed and timer are very useful.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Laboratory Micro Horizontal Jar Mill for Precision Sample Preparation in Research and Analysis

Discover the Micro Horizontal Jar Mill for precise sample preparation in research and analysis. Ideal for XRD, geology, chemistry, and more.

Laboratory Ten-Body Horizontal Jar Mill for Lab Use

The Ten-body horizontal jar mill is for 10 ball mill pots (3000ml or less). It has frequency conversion control, rubber roller movement, and PE protective cover.

Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

Efficient split chamber CVD furnace with vacuum station for intuitive sample checking and quick cooling. Up to 1200℃ max temperature with accurate MFC mass flowmeter control.

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

Efficiently prepare your samples with our Automatic Heated Lab Press. With a pressure range up to 50T and precise control, it's perfect for various industries.

Laboratory Horizontal Planetary Ball Mill Milling Machine

Improve sample uniformity with our Horizontal Planetary Ball Mills. KT-P400H reduces sample deposition and KT-P400E has multi-directional capabilities. Safe, convenient and efficient with overload protection.

Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

Discover the versatile stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining. Ideal for ceramic, chemical, metallurgical, and building materials industries. High grinding efficiency and uniform particle size.

Laboratory Four-Body Horizontal Jar Mill

The four-body horizontal tank mill ball mill can be used with four horizontal ball mill tanks with a volume of 3000ml. It is mostly used for mixing and grinding laboratory samples.

Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

Need a water circulating vacuum pump for your lab or small-scale industry? Our Benchtop Water Circulating Vacuum Pump is perfect for evaporation, distillation, crystallization, and more.

Related Articles

Basic Laboratory Centrifuge Equipment

Overview of different types of centrifuges used in laboratories.

Basic Mixing Equipment in the Laboratory

Overview of essential laboratory mixing devices and their functionalities.

Basic Laboratory Culture Equipment

Overview of essential laboratory equipment for biological and microbiological research.

Basic Cleaning and Disinfection Equipment in the Laboratory

Overview of essential lab cleaning and disinfection tools and their operational principles.

The Geometry of Trust: Stabilizing the Electrochemical Cell

Data integrity begins with physical stability. Learn how to adjust your PTFE electrode stand to master gravity, eliminate vibration, and ensure reproducibility.

Your Diamond Tester Might Be Lying: Why Moissanite Fools It and How to Get Accurate Results

Is your diamond tester giving false positives? Learn why common testers fail to spot moissanite and discover the dual-test method that ensures accuracy.