Introduction to 2D Materials

Two-dimensional (2D) materials have gained attention due to their unique properties, such as high surface area, flexibility, and electrical conductivity. These materials are composed of a single layer or a few layers of atoms or molecules, which makes them ultra-thin. Some of the most popular 2D materials include graphene, molybdenum disulfide, and hexagonal boron nitride. Due to their unique properties, 2D materials have numerous applications in various fields, such as electronics, energy storage, and biomedicine. In this blog post, we will discuss how plasma-enhanced chemical vapor deposition (PECVD) is a low-cost and scalable method for the preparation of 2D materials.

Table of Contents

Synthetic Methods for 2D Materials

Two-dimensional (2D) materials have unique properties and great potential in various applications. Controllable synthesis of 2D materials with high quality and high efficiency is essential for their large scale applications. Chemical vapor deposition (CVD) has been one of the most important and reliable techniques for the synthesis of 2D materials.

Mechanical Exfoliation

Mechanical exfoliation prepares randomly shaped materials with small size. This method involves the separation of thin layers from bulk materials using adhesive tape. The tape is pressed onto the bulk material and then peeled off, bringing some of the thin layers with it. This method is highly effective for isolating graphene, but it is not scalable, and the resulting layers are often of variable quality.

Solution Synthesis

Solution synthesis introduces impurities that degrade the performances of 2D materials. This method involves the preparation of a solution containing the precursor molecules of the desired 2D material. The solution is then heated to initiate the reaction, which results in the formation of the 2D material. Solution synthesis is a scalable method for the preparation of 2D materials, but the resulting layers are often of variable quality, and the process can introduce impurities into the material.

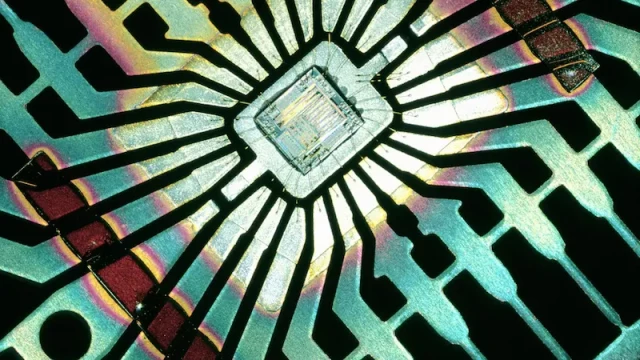

Chemical Vapor Deposition (CVD)

CVD is a time-honored technique that dates back to centuries ago. It has been recognized as a reliable synthetic method for zero-dimensional nanomaterials (quantum dots and nanocrystals) and one-dimensional nanomaterials (nanowires and nanotubes, etc.). For two-dimensional (2D) materials, the methods for synthesis mainly include mechanical exfoliation, liquid phase routes, and CVD. CVD offers a compromise between quality, efficiency, consistency, and control over the process. Therefore, it has been recognized as a reliable route for preparing high-quality 2D materials recently.

Typically, CVD growth of 2D materials involves activated chemical reactions of precursors in a specially-designed environment. The precursors, conditions, atmospheres, substrates, and catalysts (if necessary) are several key factors affecting the final quality of the 2D materials. Much progress has been made in preparing 2D materials by CVD, and many challenges must be addressed.

Plasma-Enhanced Chemical Vapor Deposition (PECVD)

PECVD is an emerging synthetic method that enables catalyst-free in situ preparation at low temperature, which is imperatively desirable. PECVD has advantages such as low temperature, transfer-free process, and industrial compatibility, which enable facile, scalable, and low-cost preparation of 2D materials with clean surfaces and interfaces directly on non-catalytic substrates. These merits significantly benefit the as-prepared materials in the applications.

PECVD or Plasma-Enhanced Chemical Vapor Deposition is a low-cost and scalable method for the preparation of 2D materials. In recent years, the demand for 2D materials has increased due to their unique and exceptional properties, which have led to many potential applications in various fields, including electronics and energy storage. PECVD is a process that uses a plasma to enhance the chemical reactions during the deposition of thin films. The process involves introducing a gas mixture into a vacuum chamber, which is then ionized by a plasma. The ions and radicals produced in the plasma then react with the substrate, resulting in the deposition of a thin film. This technique is particularly useful for the preparation of 2D materials, such as graphene and transition metal dichalcogenides, because it can produce large-area films with uniform thickness and high quality. Moreover, PECVD can be easily scaled up for mass production, making it a cost-effective method for the preparation of 2D materials. Synthetic methods for 2D materials are continually being developed, and PECVD is one that has shown promising results in terms of scalability and cost-effectiveness. As the demand for 2D materials continues to grow, the development of new and efficient synthetic methods like PECVD will be crucial in meeting the demands of various industries.

Advantages of PECVD for 2D materials

PECVD is a low-cost and scalable method that has become increasingly popular for the preparation of 2D materials. This technique uses plasma to activate the precursor gases, which are then deposited onto a substrate to form thin films of the desired material. Here are some advantages of PECVD for 2D materials:

High-Quality Films with Excellent Uniformity and Thickness Control

One of the main advantages of PECVD for 2D materials is its ability to produce high-quality films with excellent uniformity and control over thickness. This is particularly important for the development of electronic and optoelectronic devices, where precise control of the film properties is essential for optimal performance. PECVD provides a unique opportunity to deposit thin films of 2D materials with precise control over the thickness and uniformity, making it an ideal technique to fabricate complex structures and heterostructures that combine different 2D materials to achieve specific properties or functionalities.

Versatility in Depositing a Wide Range of 2D Materials

PECVD is a versatile technique that can be used to deposit a wide range of 2D materials, including graphene, MoS2, and boron nitride, among others. This means that PECVD can be used to fabricate complex structures and heterostructures that combine different 2D materials to achieve specific properties or functionalities. PECVD can be used to deposit high-quality thin films of 2D materials on a variety of substrates, including silicon, glass, and polymers, making it a promising technique for a wide range of applications.

Simple and Inexpensive Technique

PECVD is a relatively simple and inexpensive technique, which makes it accessible to a wide range of researchers and industries. PECVD systems are easy to operate and maintain, and the cost of the equipment is relatively low compared to other deposition techniques. Moreover, PECVD can be used to deposit high-quality thin films of 2D materials at low temperatures, which is suitable for heat-sensitive substrates and reduces the overall cost of the process.

Low Deposition Temperature

PECVD is a technique designed to create thin or ultrathin films on the surface of a substrate. The low deposition temperature of PECVD can lower the deposition temperature of compound films and expand the material range of substrates with compound film. For example, radiofrequency discharge and microwave discharge are suitable methods to produce a higher-density plasma at low temperatures, which is beneficial for heat-sensitive substrates.

Controllable Parameters

Compared with conventional thermal chemical vapor deposition, there are many controllable parameters in PECVD. For example, in addition to air pressure and temperature, there are discharge methods, discharge voltage, current density, ventilation method, etc. By optimizing these parameters, it is practical to obtain more excellent compound thin-film materials. PECVD allows for precise control over the deposition process, enabling the fabrication of high-quality thin films of 2D materials with specific properties and functionalities.

PECVD is a promising method for the development of next-generation electronic and optoelectronic devices, as well as for fundamental studies of 2D materials and their properties. The advantages of PECVD for 2D materials make it a promising technique for a wide range of applications, from the deposition of thin films for microelectronic devices, photovoltaic cells, and display panels to the integration of biotic and abiotic systems.

Applications of PECVD-prepared 2D materials

PECVD-prepared 2D materials have unique properties that make them suitable for various technological applications. Some of the applications of PECVD-prepared 2D materials are:

Ultra-thin and flexible electronic devices

PECVD-prepared 2D materials have exceptional mechanical strength and high electrical conductivity. These properties make them ideal for use in the development of ultra-thin and flexible electronic devices. These devices can be integrated into wearable technology, flexible displays, and sensors.

Optoelectronics

PECVD-prepared 2D materials also have excellent optical properties, such as high transparency and light absorption. These properties make them ideal for use in optoelectronics, such as solar cells, LEDs, and photodetectors.

Energy storage and conversion

PECVD-prepared 2D materials have high surface area to volume ratio, which makes them ideal for use in energy storage and conversion devices like supercapacitors and batteries. These devices have higher energy density and faster charging rates than traditional batteries.

Biomedical devices

PECVD-prepared 2D materials can also be used in the development of biomedical devices like biosensors, drug delivery systems, and tissue engineering scaffolds due to their biocompatibility and unique properties such as high surface area and mechanical strength.

Coatings and membranes

PECVD-prepared 2D materials can be used as coatings and membranes due to their exceptional barrier properties. They can be used to protect surfaces from corrosion, abrasion, and environmental factors.

PECVD-prepared 2D materials have a wide range of applications, and their unique properties make them ideal for use in various technological fields. The low-cost and scalable nature of PECVD make it an attractive method for the mass production of these materials, paving the way for their integration into a wide range of technological applications.

Advantages of CVD Graphene

CVD graphene has several advantages over other 2D materials, making it a promising material for various applications.

Excellent Mechanical, Electrical, and Thermal Properties

CVD graphene exhibits excellent mechanical, electrical, and thermal properties, making it an ideal material for a wide range of applications, including electronics, energy storage, and biomedical devices. CVD graphene is highly conductive, transparent, and flexible, which makes it an excellent choice for electronic devices where high conductivity and flexibility are crucial.

Large-Scale Production with High Quality and Uniformity

CVD graphene can be produced on a large scale with high quality and uniformity, making it a promising material for industrial applications. The CVD process can yield high-quality graphene with high homogeneity, fine grains, and good control over layer number. This makes it an ideal material for applications that require high-quality and uniform graphene.

Integration with Other Materials

CVD graphene can be integrated with other materials to form heterostructures, which can lead to the discovery of new phenomena and the development of novel devices. This makes it an attractive material for researchers and engineers looking to develop new technologies and applications.

Low-Cost and Scalable Method

PECVD, which is used to produce CVD graphene, is a low-cost and scalable method for the preparation of high-quality 2D materials. This makes it an attractive alternative to conventional chemical vapor deposition methods.

In summary, CVD graphene holds several advantages over other 2D materials, including excellent mechanical, electrical, and thermal properties, large-scale production with high quality and uniformity, integration with other materials, and being produced using a low-cost and scalable method. These advantages make CVD graphene a promising material for various applications, including electronics, energy storage, and biomedical devices.

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth