Introduction to Rotary Tube Furnaces

Rotary tube furnaces stand as pivotal tools in modern industrial landscapes, offering a gateway to enhanced efficiency and precision in materials processing. Their significance resonates through diverse sectors, from metallurgy to catalyst synthesis, owing to their capability for continuous thermal processing and meticulous temperature control. As we delve into their mechanisms and applications, a realm of possibilities unfolds, promising advancements in manufacturing alumina, iron ore pellets, and catalysts. Let's embark on a journey to uncover the intricate workings and boundless advantages of rotary tube furnaces, shaping the future of industrial innovation.

Advantages of Rotary Tube Furnaces

Rotary tube furnaces offer several key advantages, making them indispensable tools for various applications in thermal processing, material synthesis, and sample preparation. Their versatility, ease of use, efficiency in heat transfer, and precise control over process parameters make them an ideal choice for researchers and manufacturers across different fields.

Versatility

Rotary tube furnaces are highly versatile, accommodating a wide range of applications. From thermal processing to material synthesis and sample preparation, these furnaces excel in diverse tasks. Researchers and manufacturers benefit from this versatility, as it allows them to streamline their processes and adapt to different experimental needs easily.

Ease of Use

One of the notable advantages of rotary tube furnaces is their user-friendly design and straightforward operation. Equipped with simple controls and intuitive interfaces, these furnaces are accessible even to those new to furnace operations. This ease of use is particularly advantageous for researchers and technicians who may need to switch between different processing conditions frequently or for those who are exploring new applications.

Efficient Heat Transfer

Rotary tube furnaces excel in transferring heat efficiently over a short period, enabling continuous batch processing of materials. This efficiency is especially beneficial in applications such as powder processing, where minimizing material handling is crucial for maintaining product quality and process efficiency. By optimizing heat transfer, rotary tube furnaces ensure uniform processing and high throughput, enhancing overall productivity.

Precise Process Control

With features like temperature control, dwell time adjustment, and precise atmosphere regulation, rotary tube furnaces offer complete process control. Manufacturers like KinTek provide customizable options to meet specific requirements, including maximum working temperature up to 1700 degrees Celsius, workspace size, tube rotation speed, and temperature profile. This level of control allows researchers and manufacturers to fine-tune their processes for optimal results, ensuring consistent product quality and reproducibility.

Considerations for Selection

When considering whether a rotary tube furnace is suitable for a particular process, factors such as temperature control, workspace size, dwell time, tube rotation speed, and atmosphere flow rate must be taken into account. Additionally, aspects like powder bed depth and feed rate play a crucial role in determining the furnace's compatibility with specific applications. KinTek offers tailored solutions to address these requirements, ensuring optimal performance and efficiency.

In summary, rotary tube furnaces are indispensable tools for advanced materials processing, offering versatility, ease of use, efficient heat transfer, and precise process control. Whether for thermal processing, material synthesis, or sample preparation, these furnaces provide researchers and manufacturers with the capabilities needed to achieve high-quality results consistently.

Working Principle of Rotary Tube Furnaces

Rotary tube furnaces are sophisticated thermal processing systems designed for continuous material processing. They operate on the principle of indirect firing, where heat is transferred from a heat source to the process materials via a rotating tube. This section explores the fundamental working principles of rotary tube furnaces, emphasizing their indirect-fired design and continuous thermal processing capabilities.

Rotary tube furnaces employ a continuous thermal system, applying heat to the incoming process material through multiple thermal control zones. The heat can be generated using either gas or electric heating methods. The key components of a rotary tube furnace include:

-

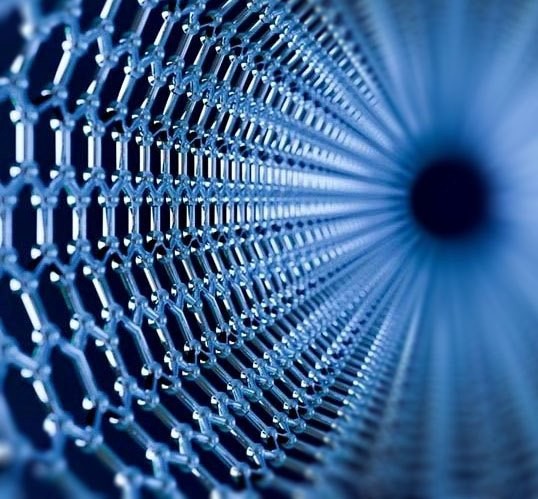

Rotating Tube: The heart of the furnace is a cylindrical tube that rotates around its axis. This tube contains the process materials and atmospheres, facilitating uniform heating and processing.

-

Indirect Firing: In an indirect-fired design, the heat source is not in direct contact with the process materials. Instead, heat is transferred to the rotating tube via radiation or convection, ensuring precise temperature control and preventing contamination of the sample.

-

Multiple Thermal Control Zones: Rotary tube furnaces feature multiple thermal control zones along the length of the tube. Each zone can be independently controlled to create specific temperature profiles, optimizing the processing conditions for different materials and applications.

The operation of a rotary tube furnace involves the following steps:

-

Heat Transfer: The heat generated by the heating elements or gas burners is transferred to the rotating tube.

-

Tube Rotation: The tube rotates continuously, ensuring uniform heating and efficient mixing of the process materials.

-

Heat Transfer to Process Materials: As the tube rotates, heat is transferred from the tube wall to the bed of material being processed. This ensures thorough heating and consistent processing throughout the material batch.

Rotary tube furnaces find extensive use across various industries and applications, including:

-

Material Synthesis: They are utilized in the production of a wide range of materials, including alumina, vermiculite, iron ore pellets, and cement clinker.

-

Oxidation and Roasting: Rotary tube furnaces are employed for oxidation processes, where oxygen is introduced to the sample, and roasting processes, which influence phase transitions in materials.

-

Powder Processing: In applications requiring precise temperature control and minimal material handling, rotary tube furnaces offer an efficient solution for powder processing.

When considering the suitability of a rotary tube furnace for a specific process, factors such as temperature control, workspace size, dwell time, rotation speed, tilt angle, atmosphere flow rate, powder bed depth, and feed rate should be taken into account. These parameters can be tailored to meet the unique requirements of each application, ensuring optimal performance and efficiency.

In summary, rotary tube furnaces play a crucial role in advanced materials processing, offering precise temperature control, continuous operation, and versatility across a wide range of applications. Their indirect-fired design and multiple thermal control zones make them indispensable tools for researchers and manufacturers alike.

Applications of Rotary Tube Furnaces

Rotary tube furnaces are versatile tools widely utilized in various industries, including metallurgy, materials science, and catalyst synthesis. Their applications span from the gaseous reduction of ores to the synthesis of catalysts and pigments, offering crucial contributions to research and materials processing endeavors.

Gaseous Reduction of Ores and Catalyst Synthesis

Rotary tube furnaces play a pivotal role in the gaseous reduction of ores and the synthesis of catalysts. By precisely controlling temperature, gas composition, and other processing parameters, researchers can study the effects of these variables on materials undergoing physicochemical transformations. This capability facilitates in-depth exploration and optimization of reduction processes, leading to advancements in metallurgy and materials science.

Analysis of Metallurgical Slags and Pigment Synthesis

In addition to ore reduction and catalyst synthesis, rotary tube furnaces are instrumental in the analysis of metallurgical slags and the synthesis of pigments. These furnaces enable researchers to subject materials to controlled heating and mixing in a controlled atmosphere, allowing for thorough analysis and experimentation. Such studies contribute to the understanding of slag composition and behavior, as well as the development of pigments for various applications such as paints and coatings.

Calcination of Oil Shale and Ceramics Doping

Another significant application of rotary tube furnaces is the calcination of oil shale, a process essential for the extraction of hydrocarbons and other organic compounds. By subjecting shale to high temperatures in a controlled environment, rotary tube furnaces facilitate the release of valuable resources, supporting industries ranging from energy production to chemical manufacturing.

Moreover, these furnaces are utilized in the doping of ceramics with rare earth metals, a process crucial for tailoring the properties of ceramics for specific applications. The precise control over temperature and atmosphere provided by rotary tube furnaces ensures uniform doping and consistent material properties, contributing to the advancement of ceramic materials science.

Advantages and Versatility

Rotary tube furnaces offer several advantages that make them indispensable tools in laboratory research and materials processing. Their ability to simultaneously heat and mix materials in a controlled atmosphere enables efficient physicochemical processing, leading to reproducible results and accelerated research progress. Additionally, the high-quality resistance wire heating elements employed in these furnaces ensure rapid heating and short cooldown times, enhancing productivity and experimental throughput.

In summary, rotary tube furnaces serve as versatile and indispensable equipment in a wide range of applications, from fundamental research to industrial materials processing. Their precise control capabilities, coupled with their efficiency and reliability, make them invaluable assets for researchers and engineers across various fields.

Conclusion: Leveraging Rotary Tube Furnaces for Enhanced Efficiency

Conclusion: Leveraging Rotary Tube Furnaces for Enhanced Efficiency

Rotary tube furnaces stand as powerful tools revolutionizing materials processing across industries. Their continuous thermal processing capabilities coupled with precise temperature control offer unparalleled advantages. From manufacturing alumina to catalyst synthesis, these furnaces ensure temperature uniformity, rapid heating, and complete process control. The indirect-fired design, along with thermal control zones, enables optimal processing conditions, driving efficiency and quality. Their applications span metallurgy, materials science, and more, driving research advancements and facilitating efficient processing. Embracing rotary tube furnaces heralds a new era of enhanced efficiency and precision in materials processing, promising endless possibilities for innovation and progress.

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Multi-zone Laboratory Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace