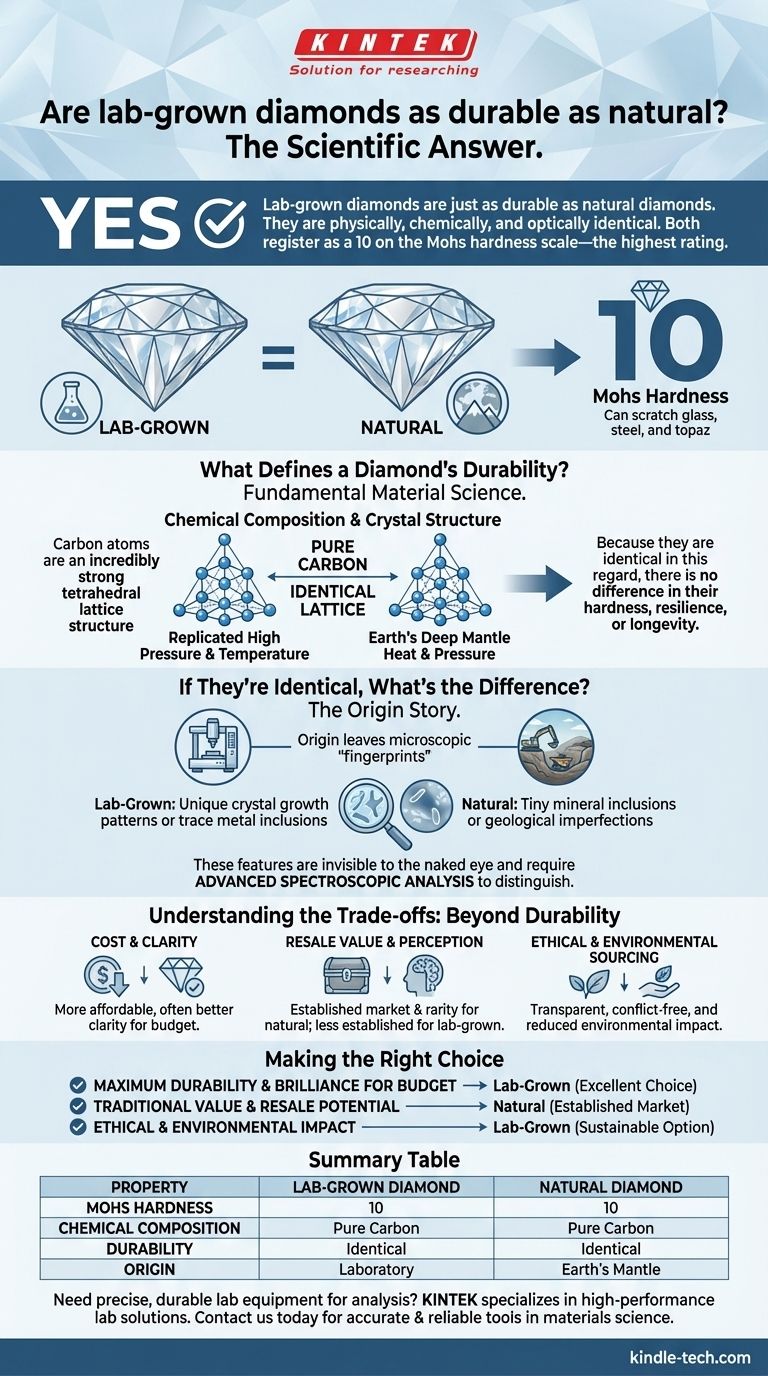

Yes, lab-grown diamonds are just as durable as natural diamonds. They are physically, chemically, and optically identical to their mined counterparts. Both are pure, crystallized carbon, and both register as a 10 on the Mohs hardness scale—the highest possible rating for any mineral.

The core takeaway is this: A diamond's durability comes from its chemical composition and crystal structure, not its origin. Because lab-grown and natural diamonds are identical in this regard, there is no difference in their hardness, resilience, or longevity.

What Defines a Diamond's Durability?

To understand why their durability is identical, we need to look at what makes a diamond "hard" in the first place. It comes down to fundamental material science.

The Role of Chemical Composition

At a molecular level, both natural and lab-grown diamonds are made of the same thing: carbon atoms bonded together in an incredibly strong lattice structure. This is the defining characteristic of a diamond.

The lab environment simply replicates the high-pressure, high-temperature conditions that create diamonds deep within the Earth. The result is a stone with the exact same chemical makeup.

The Unmatched Hardness of Carbon

A diamond's legendary durability is a direct result of this atomic structure. On the Mohs scale of mineral hardness, which measures resistance to scratching, diamonds are a 10.

This is true for any diamond, regardless of whether it was formed in the earth over billions of years or in a lab over a few weeks. They will scratch all other materials and can only be scratched by another diamond.

If They're Identical, What's the Difference?

The distinction between a lab-grown and a natural diamond is not about substance but about origin. This origin leaves behind microscopic clues that can only be identified with specialized gemological equipment.

The Difference is Origin, Not Performance

Natural diamonds are formed under immense heat and pressure in the Earth's mantle. Lab-grown diamonds are created in a controlled environment that mimics this process.

Because one process is geological and the other is manufactured, they leave different microscopic "fingerprints."

The Unique Traces of Creation

Natural diamonds often contain tiny mineral inclusions or other imperfections they acquired during their formation.

Lab-grown diamonds may have different types of inclusions (like traces of metal from the growth chamber) or exhibit unique crystal growth patterns. These features are invisible to the naked eye but act as a marker of their origin.

Why It Takes an Expert to Tell

You cannot distinguish a lab-grown diamond from a natural one by looking at it, even with a standard jeweler's loupe. It requires advanced spectroscopic analysis to identify the subtle differences in their atomic structure and growth patterns.

Understanding the Trade-offs

Choosing between a lab-grown and a natural diamond involves weighing factors beyond durability, where they are equal. The real differences lie in value, perception, and ethics.

Cost and Clarity

Lab-grown diamonds are significantly more affordable than natural diamonds of the same size and quality.

Furthermore, because they are grown in a controlled environment, lab diamonds often have fewer inclusions and blemishes, meaning you can often get a higher clarity grade for your budget.

Resale Value and Perception

Natural diamonds have a long-established history and a robust resale market built on their perceived rarity.

The long-term resale value of lab-grown diamonds is less established. For many, the choice comes down to personal preference: the timeless story of a natural stone versus the modern innovation of a lab-created one.

Ethical and Environmental Sourcing

Lab-grown diamonds offer a clear and transparent supply chain. They are inherently conflict-free and avoid the environmental impact associated with traditional mining, which is a primary consideration for many buyers.

Making the Right Choice for Your Goal

Since durability is not a deciding factor, your choice depends entirely on your priorities.

- If your primary focus is maximum durability and brilliance for your budget: A lab-grown diamond is an excellent choice, offering the same physical performance and often better clarity at a lower price.

- If your primary focus is traditional value and long-term resale potential: A natural diamond holds a more established position in the market due to its history and geological rarity.

- If your primary focus is ethical and environmental impact: A lab-grown diamond provides a transparent, conflict-free, and more sustainable option.

Ultimately, the choice depends on whether you value geological origin or modern innovation, as both paths lead to an equally durable and brilliant genuine diamond.

Summary Table:

| Property | Lab-Grown Diamond | Natural Diamond |

|---|---|---|

| Mohs Hardness | 10 | 10 |

| Chemical Composition | Pure Carbon | Pure Carbon |

| Durability | Identical | Identical |

| Origin | Laboratory | Earth's Mantle |

Need precise, durable lab equipment to analyze or create materials like diamonds? KINTEK specializes in high-performance lab equipment and consumables, serving all your laboratory needs. Whether you're in materials science, research, or quality control, our tools ensure accuracy and reliability. Contact our experts today to find the perfect solution for your lab!

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Optical Windows for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- Are lab-grown diamonds less durable than natural diamonds? They're Identical in Hardness and Resilience

- What is MPCVD method? A Guide to High-Purity Diamond Synthesis

- Why do lab diamond prices vary so much? Understand the 4Cs and Market Forces

- How does microwave generate plasma? Unlocking the Physics of Energy Concentration

- Do lab-grown diamonds last as long? Yes, They Offer the Same Unmatched Durability

- Why is MW-CVD preferred for high-purity diamond optical windows? Achieve Zero-Contamination Material Growth

- What is CVD diamond? The Ultimate Guide to Lab-Grown Diamonds and Their Uses

- What are the benefits of microwave plasma process? Achieve Faster, More Uniform Heating for Advanced Materials