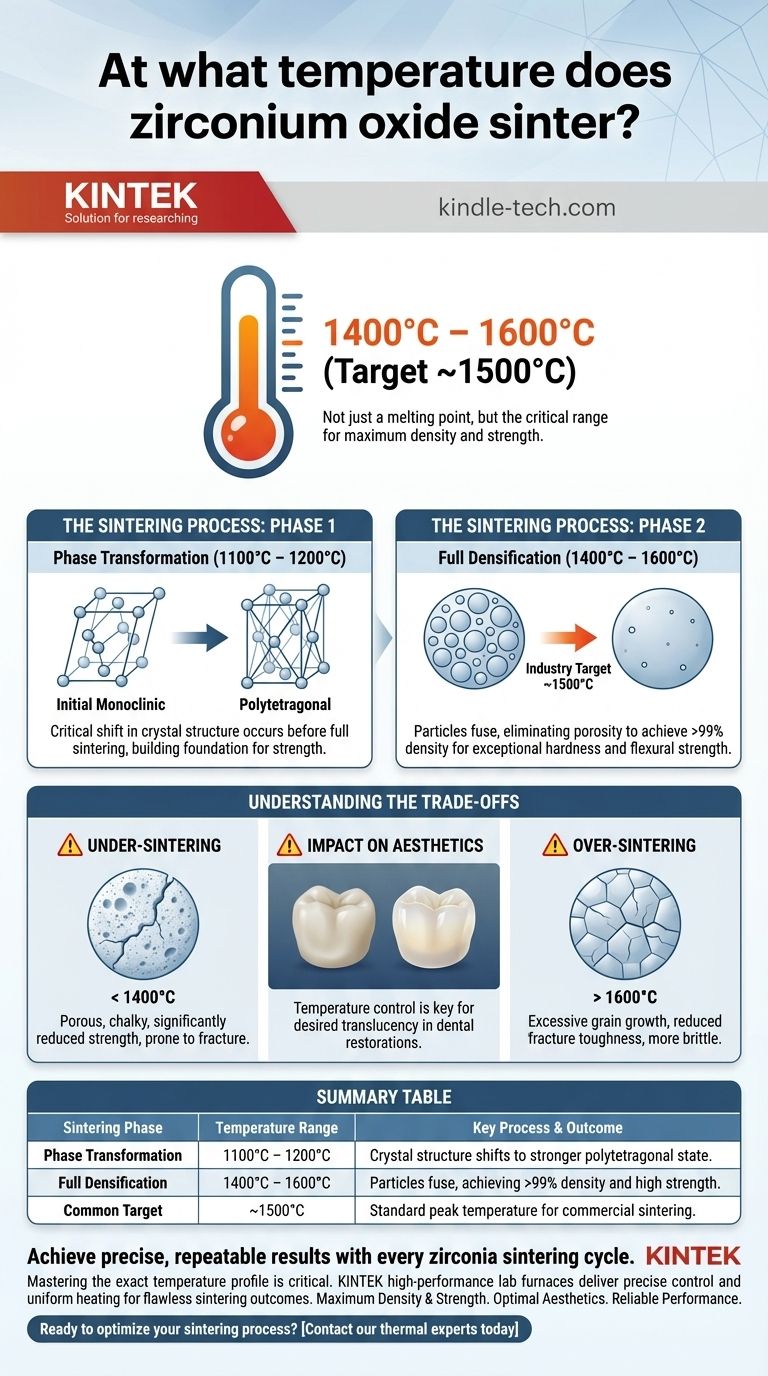

While the process begins at lower temperatures, zirconium oxide (zirconia) is typically sintered in a range of 1400°C to 1600°C. The most common target temperature within this range is approximately 1500°C. This is not merely a melting point but the specific temperature required to achieve maximum density and, consequently, the desired hardness and mechanical strength for high-performance applications.

The specific sintering temperature is less a single number and more a critical processing parameter. The goal is to drive a crystalline transformation and then fuse the material's particles together, eliminating porosity to achieve nearly 100% theoretical density.

The Sintering Process: A Tale of Two Temperatures

Understanding the zirconia sintering process requires looking beyond a single number. The process involves distinct phases that occur at different temperature ranges, each contributing to the final properties of the material.

The Foundational Shift: Phase Transformation (1100°C – 1200°C)

Before full sintering occurs, zirconia undergoes a critical change in its crystal structure.

At around 1100°C, the material begins to transform from its initial monoclinic state to a much stronger polytetragonal crystalline state. This transformation is fundamental to achieving the final strength of the sintered part.

The Goal: Full Densification (1400°C – 1600°C)

This higher temperature range is where the actual sintering and densification happen.

In this range, the individual zirconia particles fuse together, dramatically reducing the empty space (porosity) between them. The standard industry target is to reach a final density that is greater than 99% of the theoretical maximum.

Achieving this high density is directly responsible for the material's exceptional hardness and flexural strength, which are critical for both dental and industrial applications. Most commercial sintering furnaces operate at a peak temperature of around 1500°C to ensure this process is completed.

Understanding the Trade-offs

Simply reaching the target temperature is not enough. The entire heating and cooling cycle matters, and deviating from the optimal process carries significant risks that compromise the final component.

The Risk of Under-Sintering

If the furnace does not reach the required 1400°C+ temperature or does not hold it long enough, densification will be incomplete.

The resulting part will be porous, chalky, and have significantly reduced strength. It will be prone to fracture and completely unsuitable for any load-bearing application.

The Impact on Aesthetics

In applications like dental restorations, temperature control is also key to achieving the desired translucency.

Different types of dental zirconia are engineered to provide varying levels of translucency, and their specific sintering profiles are designed to optimize this aesthetic property alongside strength. Using the wrong temperature can make a crown appear too opaque or unnatural.

The Danger of Over-Sintering

Conversely, firing at excessively high temperatures or for too long can also be detrimental.

This can lead to excessive grain growth within the material's microstructure. While the part may be dense, these oversized grains can paradoxically reduce the material's fracture toughness, making it more brittle.

Making the Right Choice for Your Goal

The correct sintering profile depends entirely on the material you are using and the properties you need to achieve. Always begin with the manufacturer's specific instructions for their zirconia.

- If your primary focus is maximum strength and density: You will need to operate within the 1400°C to 1600°C range, ensuring the cycle allows for full densification to >99%.

- If your primary focus is balancing strength with aesthetics (e.g., dental crowns): Adhere strictly to the manufacturer's validated cycle for that specific zirconia puck, as the peak temperature is fine-tuned to achieve a specific translucency.

Ultimately, precise control over the sintering temperature is how you transform zirconia powder into a high-performance ceramic component.

Summary Table:

| Sintering Phase | Temperature Range | Key Process & Outcome |

|---|---|---|

| Phase Transformation | 1100°C – 1200°C | Crystal structure shifts to a stronger polytetragonal state. |

| Full Densification | 1400°C – 1600°C | Particles fuse, eliminating porosity to achieve >99% density and high strength. |

| Common Target | ~1500°C | Standard peak temperature for most commercial sintering processes. |

Achieve precise, repeatable results with every zirconia sintering cycle.

Mastering the exact temperature profile is critical for transforming zirconia pucks into strong, aesthetically perfect components. KINTEK specializes in high-performance lab furnaces that deliver the precise temperature control and uniform heating required for flawless sintering outcomes.

Our sintering furnaces are trusted by dental labs and industrial manufacturers to ensure:

- Maximum Density & Strength: Achieve consistent results exceeding 99% theoretical density.

- Optimal Aesthetics: Perfectly execute manufacturer-recommended cycles for ideal translucency in dental restorations.

- Reliable Performance: Avoid the risks of under-sintering or over-sintering with stable, accurate temperature management.

Ready to optimize your sintering process? Contact our thermal experts today to find the perfect furnace for your laboratory's needs.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the body structure of a furnace? Unlocking the Dual-Layer Design for Superior Thermal Control

- At what temperature does quartz soften? Understand the practical limits for lab equipment

- What is the use of muffle furnace in food industry? Essential for Accurate Food Ash Analysis

- What is the difference between a muffle furnace and a chamber furnace? Understand the Key Distinctions for Your Lab

- What are the five common heat treatments of metals? Master the Processes for Precise Material Properties