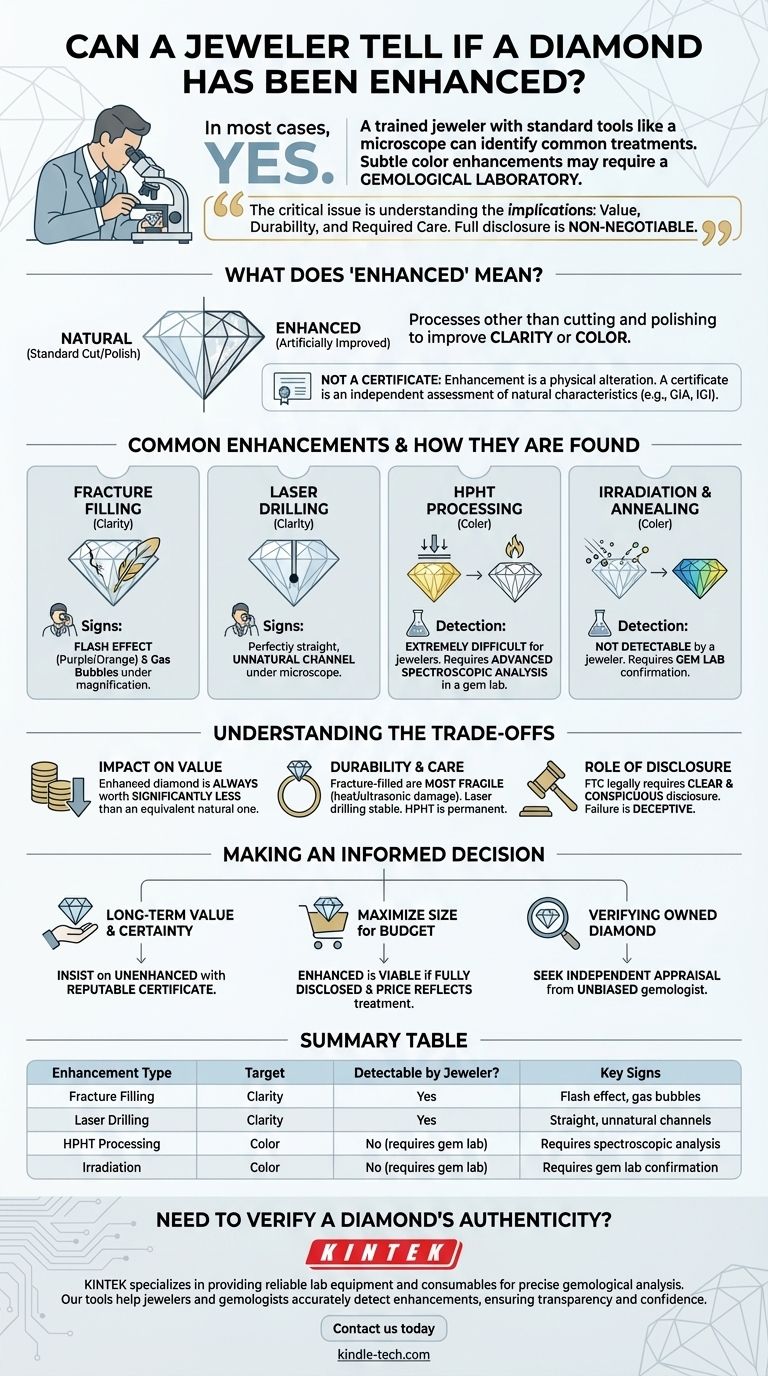

In most cases, yes. A trained jeweler or, more specifically, a certified gemologist can identify common diamond enhancements using standard tools like a microscope. Treatments such as fracture filling and laser drilling leave tell-tale signs. However, some sophisticated enhancements that alter a diamond's fundamental color are far more subtle and may require the advanced equipment of a gemological laboratory for definitive identification.

While detection is often possible, the more critical issue is understanding the implications of an enhancement. These treatments significantly affect a diamond's value, durability, and required care, making full and transparent disclosure from the seller a non-negotiable standard.

First, What Does "Enhanced" Mean?

Defining the Term

A diamond enhancement is any process other than standard cutting and polishing that is used to artificially improve the stone's apparent quality. These treatments typically target a diamond's clarity or its color.

Not to Be Confused with Certification

Enhancement is a physical alteration of the diamond itself. This is entirely different from a diamond certificate or grading report (like one from GIA or IGI), which is an independent assessment of the diamond's natural characteristics. Reputable reports will always disclose any detected enhancements.

Common Enhancements and How They Are Found

Fracture Filling (Clarity Enhancement)

This is the most common clarity enhancement. A microscopic surface-reaching fracture or "feather" is filled with a glass-like resin that has a refractive index similar to diamond. This makes the inclusion much harder to see.

A trained jeweler can spot this under magnification by looking for a "flash effect"—subtle flashes of color (often purple or orange) that appear when the diamond is rocked back and forth. Tiny gas bubbles trapped within the filling are another dead giveaway.

Laser Drilling (Clarity Enhancement)

In this process, a high-powered laser burns a microscopic tunnel from the surface of the diamond to a dark internal inclusion (like a black carbon spot). The inclusion can then be vaporized or bleached with an acid.

This is detected under a microscope as a perfectly straight, unnatural-looking channel. Sometimes these drill channels are also filled, which combines the challenges of detecting both treatments.

HPHT Processing (Color Enhancement)

High-Pressure, High-Temperature (HPHT) treatment mimics the natural conditions deep within the Earth that form diamonds. It can be used to permanently improve the color of certain types of diamonds, often turning a yellowish or brownish stone into a more valuable colorless one.

Detecting HPHT is extremely difficult for a retail jeweler. It requires advanced spectroscopic analysis in a gem lab. The most reliable way for a consumer to know if a diamond is HPHT-treated is through the comments section of a GIA or IGI grading report.

Irradiation and Annealing (Color Enhancement)

This process uses a particle accelerator or nuclear reactor to alter the diamond's crystal lattice, inducing color. It is most often used to create fancy-colored diamonds, such as vibrant greens, blues, or yellows.

Like HPHT, this treatment is generally not detectable by a jeweler and requires a gem lab for confirmation. The color is often considered stable, but it can be affected by the extreme heat of a jeweler's torch during repairs.

Understanding the Trade-offs and Implications

The Impact on Value

This is the single most important takeaway: an enhanced diamond is always worth significantly less than a natural, unenhanced diamond of the same apparent quality. The enhancement is a shortcut to a look that would naturally command a much higher price.

The Question of Durability and Care

Fracture-filled diamonds are the most fragile. The filling can be damaged or even melt out if exposed to high heat (like during a ring resizing) or ultrasonic cleaners. This treatment is not permanent. Laser drill holes are microscopic weaknesses, but they are generally stable. HPHT is a permanent and stable treatment.

The Critical Role of Disclosure

In the United States and many other regions, the Federal Trade Commission (FTC) legally requires sellers to clearly and conspicuously disclose all diamond enhancements. Failure to do so is a deceptive practice. A seller who is not forthcoming about treatments should not be trusted.

Making an Informed Decision

Whether you are buying a new diamond or assessing one you own, your goal determines your path. The key is to have complete information before making a choice.

- If your primary focus is long-term value and certainty: Insist on an unenhanced diamond with a reputable GIA or IGI certificate that explicitly states no treatments are present.

- If your goal is to maximize size for your budget: An enhanced diamond can be a viable option, but only if the treatment is fully disclosed, the price fairly reflects the enhancement, and you understand the special care instructions.

- If you are verifying a diamond you already own: Seek an independent appraisal from a certified gemologist who is not affiliated with the original seller to get an unbiased assessment of its quality and any present treatments.

Ultimately, knowledge of these enhancements empowers you to purchase not just a beautiful stone, but one whose quality and value you can be truly confident in.

Summary Table:

| Enhancement Type | Target | Detectable by Jeweler? | Key Signs |

|---|---|---|---|

| Fracture Filling | Clarity | Yes | Flash effect, gas bubbles under magnification |

| Laser Drilling | Clarity | Yes | Straight, unnatural-looking channels |

| HPHT Processing | Color | No (requires gem lab) | Requires spectroscopic analysis |

| Irradiation | Color | No (requires gem lab) | Requires gem lab confirmation |

Need to verify a diamond's authenticity or understand its treatment history? KINTEK specializes in providing reliable lab equipment and consumables for precise gemological analysis. Our tools help jewelers and gemologists accurately detect enhancements, ensuring transparency and confidence in your diamond assessments.

Contact us today to learn how our solutions can support your laboratory's needs and enhance your diagnostic capabilities.

Visual Guide

Related Products

- CVD Diamond Dressing Tools for Precision Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Automatic Laboratory Heat Press Machine

- Infrared High Resistance Single Crystal Silicon Lens

People Also Ask

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What are the advantages of the CVD diamond growing process compared to the HPHT process? Master Precision & Efficiency

- What are the properties of diamond coating? Unlock Extreme Performance for Your Components

- What is the application of diamond coating? Solve Complex Wear, Heat, and Corrosion Problems

- How thick is diamond coating? Achieve Unprecedented Precision with Ultra-Thin Films