In principle, yes, a laboratory oven can be set to the same temperature as an incubator, but it should not be used as a substitute for one. While both are insulated boxes that heat their interior, their core designs are for fundamentally different tasks. Using an oven for incubation is a significant risk to your samples due to its lack of temperature stability and uniformity at the low temperatures required for biological growth.

The crucial difference is not if they can reach a temperature, but how they maintain it. An incubator is engineered for gentle, highly stable, and uniform warmth आदर्श for sensitive biological applications, whereas an oven is built for aggressive, high-temperature heating and drying, making it unsuitable for delicate work.

The Fundamental Difference: Design and Purpose

To understand the risk, you must first appreciate that these instruments are engineered to solve different problems. Their similarities, such as insulation and safety thermostats, are superficial.

An Oven's Purpose: High-Heat Applications

A laboratory oven is designed for processes like drying, curing, or dry-heat sterilization. Its heating elements are powerful, built to reach high temperatures (often well over 200°C) efficiently.

The control systems in ovens are optimized for this high-temperature range. Their primary goal is to inject large amounts of heat to remove moisture or induce chemical changes.

An Incubator's Purpose: Stable Biological Growth

A laboratory incubator is designed to create a stable environment for the growth of living organisms, such as cell cultures or bacteria. Its entire system is optimized for precision in a much lower temperature range, typically from ambient to a maximum of 80-100°C.

The goal is not just heating, but maintaining a state of equilibrium with minimal fluctuation, což is critical for the survival and growth of biological samples.

Why a Lab Oven Fails as an Incubator

Using an oven for a task it wasn't designed for introduces several critical points of failure.

Poor Temperature Stability

An oven's thermostat is not precise enough for low-temperature incubation. It often works by heating aggressively until it passes the setpoint, then shutting off and cooling down until it drops below the setpoint.

This creates a temperature "overshoot" and "undershoot" cycle. While this might average out to your target temperature, a brief spike of just a few degrees can be lethal to sensitive cells, microbes, or proteins, irreversibly ruining your experiment.

Lack of Temperature Uniformity

Ovens,特别是那些依赖自然对流的,are prone to "hot spots." The areas nearest the heating elements will be significantly warmer than other parts of the chamber.

Incubators, in contrast, are often designed with features like water jackets or forced air circulation to ensure the temperature is exceptionally uniform throughout the entire chamber. Placing samples in an oven means their fate could depend entirely on their position on the shelf.

Absence of Humidity Control

Many biological applications require a humid environment to prevent samples from drying out. Incubators are often equipped with humidity controls or, at a minimum, a water pan to maintain relative humidity.

Laboratory ovens are designed for the exact opposite purpose: to remove moisture. Running an oven, even at a low temperature, will actively dehydrate your samples.

Understanding the Trade-offs

While the advice is to always use the right tool, it's important to understand the specific risks you are accepting if you choose to proceed with an oven.

For Non-Critical Warming

If you are simply warming a buffer or a non-sensitive material where a fluctuation of several degrees is irrelevant, an oven might suffice. However, this is not "incubation."

For Extremely Robust Organisms

Some rugged organisms might survive the temperature swings of an oven, but your results will be inconsistent. You will not be able to produce reliable or reproducible data, which is the foundation of sound science.

The Hidden Cost of Failure

Consider the value of your samples, your time, and the reagents used. The cost of a failed experiment due to using the wrong equipment almost always exceeds the cost of finding and using a proper incubator.

Making the Right Choice for Your Goal

Your decision should be dictated广告 by the requirements of your work and your tolerance for risk.

- If your primary focus is growing sensitive biological samples (e.g., cell cultures, bacteria): Do not use an oven. The high risk of temperature overshoot, hot spots, and dehydration will likely destroy your samples and invalidate your results.

- If your primary focus is a rough, non-critical warming task: You might use an oven, but you must first validate its stability at your target temperature with an independent, calibrated thermometer and accept the high risk of inconsistency.

- If your primary focus is ensuring reproducible and reliable scientific outcomes: Always use the correct instrument. Use an incubator for incubation and an oven for drying and high-heat applications.

Choosing the right instrument is the first and most critical step toward achieving reliable and successful outcomes.

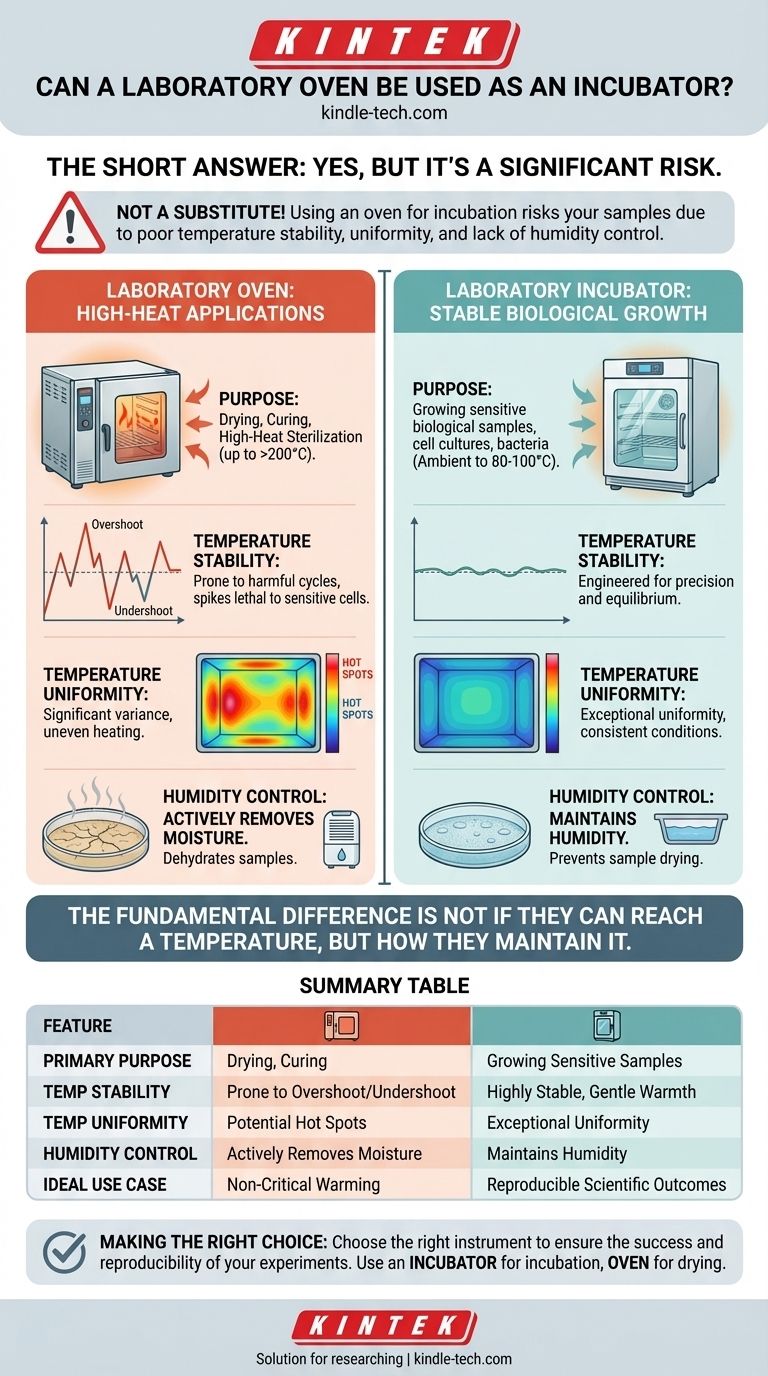

Summary Table:

| Feature | Laboratory Oven | Laboratory Incubator |

|---|---|---|

| Primary Purpose | Drying, curing, high-heat sterilization | Growing sensitive biological samples (cells, bacteria) |

| Temperature Stability | Prone to overshoot/undershoot cycles | Engineered for highly stable, gentle warmth |

| Temperature Uniformity | Potential for hot spots, especially in natural convection models | Designed for exceptional uniformity throughout the chamber |

| Humidity Control | Actively removes moisture (dehydrates samples) | Often includes controls or water pans to maintain humidity |

| Ideal Use Case | Non-critical warming of robust materials | Reproducible growth of sensitive cultures and reliable scientific outcomes |

Ensure the success and reproducibility of your experiments by using the right instrument for the job.

At KINTEK, we specialize in providing reliable laboratory equipment tailored to your specific needs. Whether you require a precise incubator for sensitive cell cultures or a robust oven for drying applications, our experts can help you select the perfect solution to protect your samples and ensure accurate results.

Don't risk your valuable research—contact our team today to find the ideal equipment for your laboratory!

Visual Guide

Related Products

- 1200℃ Muffle Furnace Oven for Laboratory

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Automatic Laboratory Heat Press Machine

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- How do you sterilize glassware without an autoclave? A Step-by-Step Guide to Dry Heat Sterilization

- What is the importance of precise programmed temperature control in a high-temperature furnace? Master Co-Sintering

- What role does a high-temperature box furnace play during the re-austenitization of 17-4 PH? Transform SLM Performance

- What is ashing in chemistry? Enhance Analytical Accuracy with Ashing Techniques