No, not all plastics are suitable for pyrolysis. While the technology is a powerful tool for chemical recycling, its effectiveness and economic viability are highly dependent on the type of plastic used as a feedstock. The chemical structure of each plastic dictates not only the quality and yield of the final products but also the operational safety and longevity of the equipment itself.

The success of a plastic pyrolysis project is determined before the process even begins—by the feedstock. While many common plastics can be converted into valuable fuel, certain types like PVC and PET introduce significant chemical challenges that can corrode equipment, contaminate the output, and undermine the entire operation.

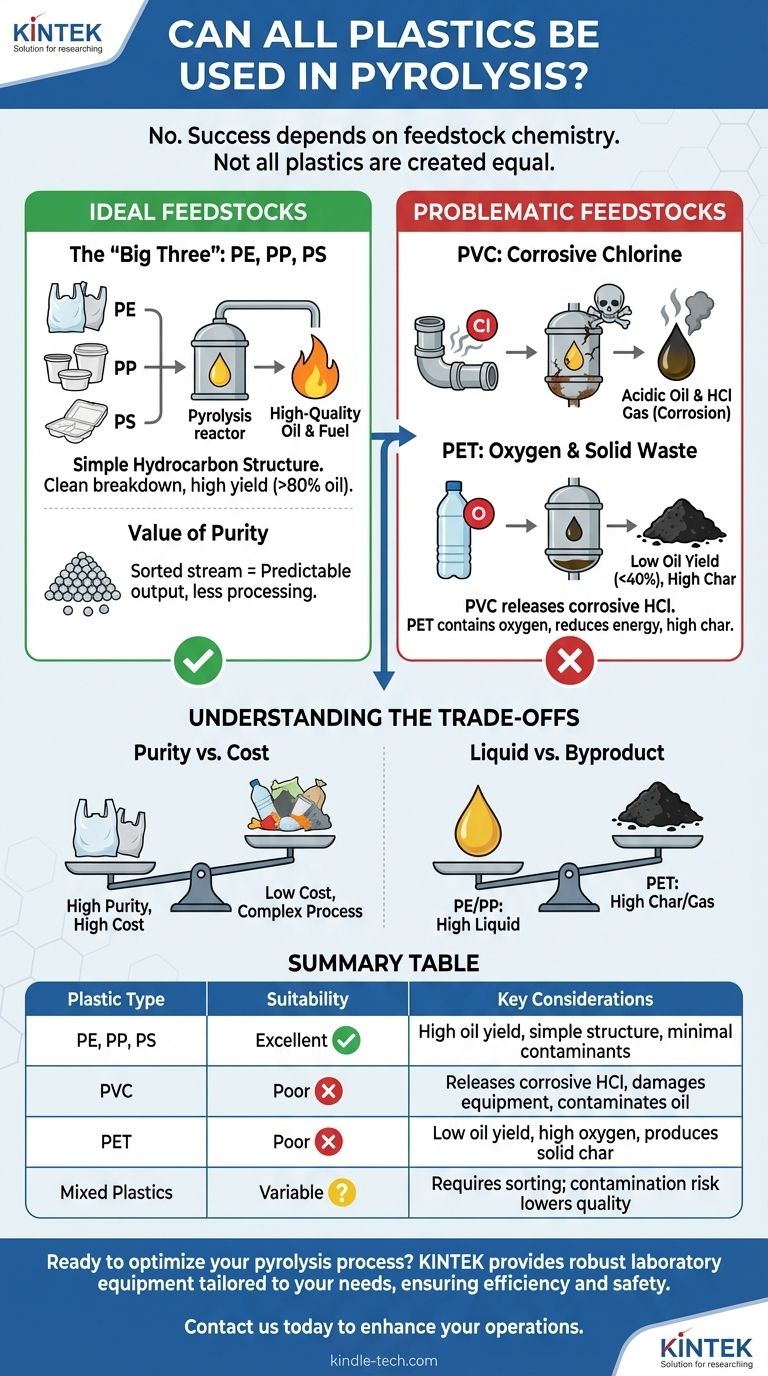

Why Some Plastics are Ideal for Pyrolysis

The goal of pyrolysis is to break down long polymer chains into smaller, valuable hydrocarbon molecules, primarily in the form of a liquid oil. The best plastics for this are those with a simple structure made almost entirely of carbon and hydrogen.

The "Big Three": PE, PP, and PS

The most desirable feedstocks are Polyethylene (PE), Polypropylene (PP), and Polystyrene (PS). These plastics are found in everything from plastic bags and containers to packaging foam. Their simple hydrocarbon backbones break down cleanly into compounds similar to those found in conventional diesel and gasoline, resulting in a high-quality pyrolysis oil.

The Value of Purity

A homogeneous feedstock—one made of a single type of plastic—yields the most predictable and valuable output. Sorting plastics by type before pyrolysis ensures a consistent process and a higher-grade oil that requires less post-processing.

Problematic Plastics and the Challenges They Pose

Not all plastics break down as cleanly. Certain polymers contain other elements in their chemical structure that create significant operational and environmental hurdles during pyrolysis.

The PVC Problem: Corrosive Chlorine

Polyvinyl Chloride (PVC) is the most problematic plastic for pyrolysis. When heated, the chlorine in its structure is released as hydrochloric acid (HCl) gas. This acid is highly corrosive to steel reactors, pipes, and condensers, leading to rapid equipment failure and costly downtime. It also contaminates the final oil, making it acidic and unusable without further, expensive treatment.

The PET Challenge: Oxygen and Solid Waste

Polyethylene Terephthalate (PET), commonly used for beverage bottles, is also less than ideal. Its chemical structure contains oxygen atoms. During pyrolysis, this oxygen ends up in the liquid oil, reducing its energy content and stability. PET also tends to produce a much higher proportion of solid char (waste) compared to liquid fuel, lowering the overall efficiency of the conversion process.

The Impact of Contaminants

Even with the "good" plastics, contamination is a major concern. Additives like dyes, flame retardants, and plasticizers, as well as non-plastic materials mixed in the waste stream, can introduce unwanted chemicals into the outputs, complicating the process and reducing the final product's value.

Understanding the Trade-offs

Choosing a feedstock is a balancing act between ideal chemistry and practical reality. Your decision involves critical trade-offs that impact both cost and performance.

Feedstock Purity vs. Processing Cost

Using a clean, sorted stream of PE and PP will produce the best oil, but sorting post-consumer plastic waste is labor-intensive and expensive. Using unsorted municipal solid waste (MSW) or mixed plastics is cheaper upfront but leads to a lower-grade oil and requires a more robust, complex, and expensive pyrolysis system to handle contaminants.

Handling Difficult Streams

It is technically possible to process difficult materials like multi-layer packaging or PVC-contaminated plastics, as some advanced systems do. However, this requires specialized pre-treatment steps (like de-chlorination) and more resilient reactors, significantly increasing both capital investment and operational complexity.

Liquid Yield vs. Byproduct Management

The type of plastic directly influences the ratio of products. While PE and PP can yield over 80% liquid oil by weight, PET might yield less than 40% oil and a large amount of solid char. You must have a plan to manage and dispose of or utilize all outputs, including the non-condensable gas and the solid residue.

Making the Right Choice for Your Goal

Your feedstock strategy should be directly aligned with your primary objective.

- If your primary focus is maximizing high-quality oil yield: Prioritize clean, sorted streams of Polyethylene (PE), Polypropylene (PP), and Polystyrene (PS).

- If your primary focus is waste volume reduction at scale: Prepare for significant investment in pre-sorting and a robust system capable of handling mixed plastics, and accept that the oil will likely require further upgrading.

- If you must process difficult feedstocks like PET or PVC: Invest in specialized pyrolysis technologies designed to mitigate corrosion and handle oxygenated compounds, and budget for higher operational costs.

Ultimately, a successful pyrolysis operation is built upon a deep understanding of your feedstock's chemistry.

Summary Table:

| Plastic Type | Pyrolysis Suitability | Key Considerations |

|---|---|---|

| PE, PP, PS | Excellent | High oil yield, simple hydrocarbon structure, minimal contaminants |

| PVC | Poor | Releases corrosive HCl gas, damages equipment, contaminates oil |

| PET | Poor | Low oil yield, high oxygen content, produces solid char waste |

| Mixed Plastics | Variable | Requires sorting; contamination risk lowers oil quality |

Ready to optimize your pyrolysis process with the right feedstock?

At KINTEK, we specialize in providing robust laboratory equipment and consumables tailored to your chemical recycling needs. Whether you're processing PE, PP, or tackling challenging materials like PVC, our solutions ensure efficiency, safety, and high-quality output.

Contact us today to discuss how our expertise can enhance your pyrolysis operations and help you achieve superior results. Get in touch now!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Powerful Plastic Crusher Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- In which three ways can we use biomass as a source of energy? Harnessing Organic Matter for Power

- How do you keep the temperature constant in a lab? Master Precise Thermal Control for Reliable Results

- What are the safety precautions for brazing welding? A 4-Pillar System for Avoiding Toxic Fumes, Burns & Fires

- What is bio-oil used for pyrolysis? Unlocking Renewable Fuel & Chemical Potential

- What is the role of a laboratory drying oven in cellulose citrate production? Ensure Material Stability & Purity

- What gas is used in sputtering? Optimize Your Thin Film Deposition Process

- How can we reduce plastic waste using technology? Leverage AI, Chemical Recycling & Bioplastics

- What machine is used for casting? The Definitive Guide to Die Casting Machines