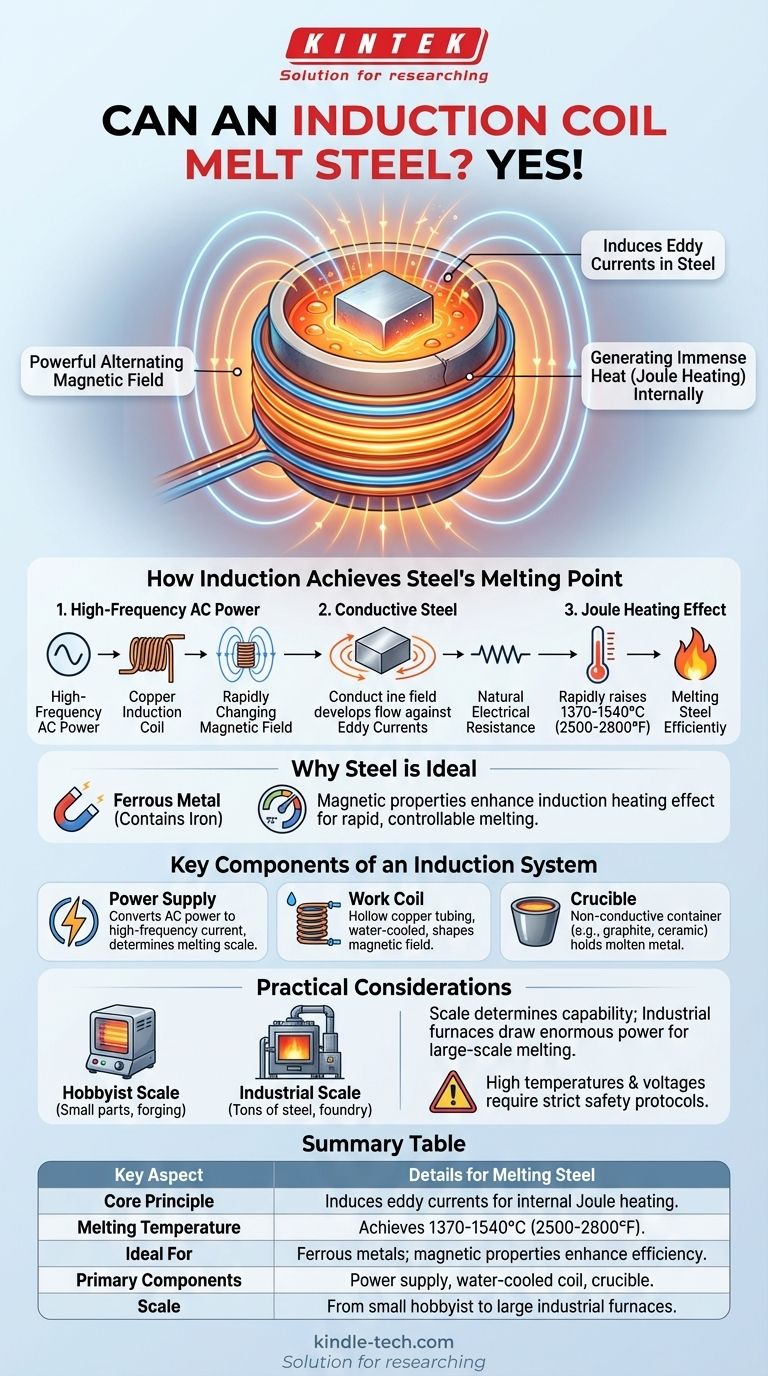

Yes, an induction coil is the core component of a system designed to melt steel. An induction furnace, which uses a powerful induction coil, is a standard industrial method for melting steel and other ferrous metals. It works by using a strong, alternating magnetic field to induce electrical currents directly within the steel, generating immense heat very quickly and efficiently.

The core principle is not about external flame, but about turning the metal itself into the source of heat. An induction system is fully capable of reaching the high temperatures required to melt steel, provided the power supply and coil are properly designed for the task.

How Induction Achieves Steel's Melting Point

The Principle of Induction Heating

An induction heater works by passing a high-frequency alternating current (AC) through a copper coil.

This creates a rapidly changing magnetic field around and within the coil.

When a conductive material like steel is placed inside this field, the magnetic field induces powerful electrical currents, known as eddy currents, to flow within the metal.

Turning Electricity into Heat

The steel has natural electrical resistance. As these strong eddy currents flow against this resistance, they generate tremendous heat through a process called Joule heating.

This effect is so powerful and concentrated that it can rapidly raise the temperature of the steel past its melting point, which is typically between 1370-1540°C (2500-2800°F).

Why Steel is an Ideal Material

Steel is a ferrous metal, meaning it contains iron. Its magnetic properties enhance the induction heating effect, making it much more efficient to heat than non-magnetic metals like aluminum or copper.

The system essentially turns the piece of steel into its own heating element, allowing for clean, controllable, and rapid melting without direct contact from a heat source.

Key Components of an Induction System

The Power Supply

This is the heart of the system. It takes standard electrical power and converts it into the high-frequency, high-current AC power needed to drive the coil. The power supply's wattage directly determines how much metal you can melt and how quickly.

The Work Coil

This is the copper coil that creates the magnetic field. Its shape and size are critical and must be designed to match the workpiece (the steel) for maximum efficiency. Water is often circulated through the hollow copper tubing to prevent the coil itself from melting.

The Crucible

When melting metal, a non-conductive, high-temperature container called a crucible is used to hold the molten steel. The crucible is placed inside the coil, and it isolates the molten metal from the coil itself. Materials like graphite or ceramic are common.

Understanding the Practical Considerations

Scale and Power Requirements

A small, benchtop induction heater used by hobbyists might be able to melt a nail or a small screw, but it will not melt a significant block of steel.

Industrial induction furnaces are massive systems that draw enormous amounts of power. They are specifically designed to melt tons of steel for foundries and manufacturing. The capability to melt steel is entirely dependent on the scale of the equipment.

Efficiency and Control

Induction heating is highly efficient because the heat is generated directly within the material. There is very little waste heat compared to a traditional fuel-fired furnace.

It also offers precise temperature control, which is critical for creating specific steel alloys. By adjusting the power and frequency, operators can manage the melting process with great accuracy.

Safety

These systems involve extremely high temperatures and high voltages. Industrial units are contained and operated with strict safety protocols. Even smaller units pose significant risks of severe burns and electrical shock and must be handled with extreme care.

Making the Right Choice for Your Goal

If your primary focus is industrial manufacturing or large-scale metalworking: An induction furnace is a standard, highly efficient, and controllable method for melting steel to produce alloys or for casting.

If your primary focus is a small-scale hobby or workshop project: A smaller induction heater can certainly heat steel to red-hot temperatures for forging or hardening, but melting anything more than a very small piece will require a specialized and powerful unit.

This technology provides a clean, fast, and precise method for turning solid steel into a liquid state.

Summary Table:

| Key Aspect | Details for Melting Steel |

|---|---|

| Core Principle | Induces eddy currents within the steel, generating internal heat (Joule heating). |

| Melting Temperature | Achieves 1370-1540°C (2500-2800°F), sufficient for steel. |

| Ideal For | Ferrous metals like steel; magnetic properties enhance efficiency. |

| Primary Components | Power supply, water-cooled copper coil, and a ceramic/graphite crucible. |

| Scale | From small hobbyist units to large industrial furnaces melting tons of metal. |

Ready to integrate precise, efficient induction heating into your lab or production line? KINTEK specializes in high-performance lab equipment and consumables, including induction heating systems designed for reliability and control. Whether you're developing new alloys or need precise melting capabilities, our solutions are tailored to meet rigorous laboratory and industrial demands. Contact our experts today to discuss how we can support your specific project goals.

Visual Guide

Related Products

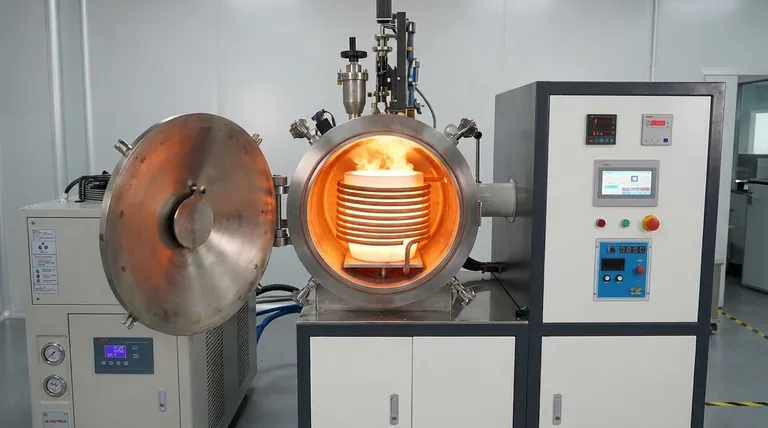

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Three-dimensional electromagnetic sieving instrument

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision