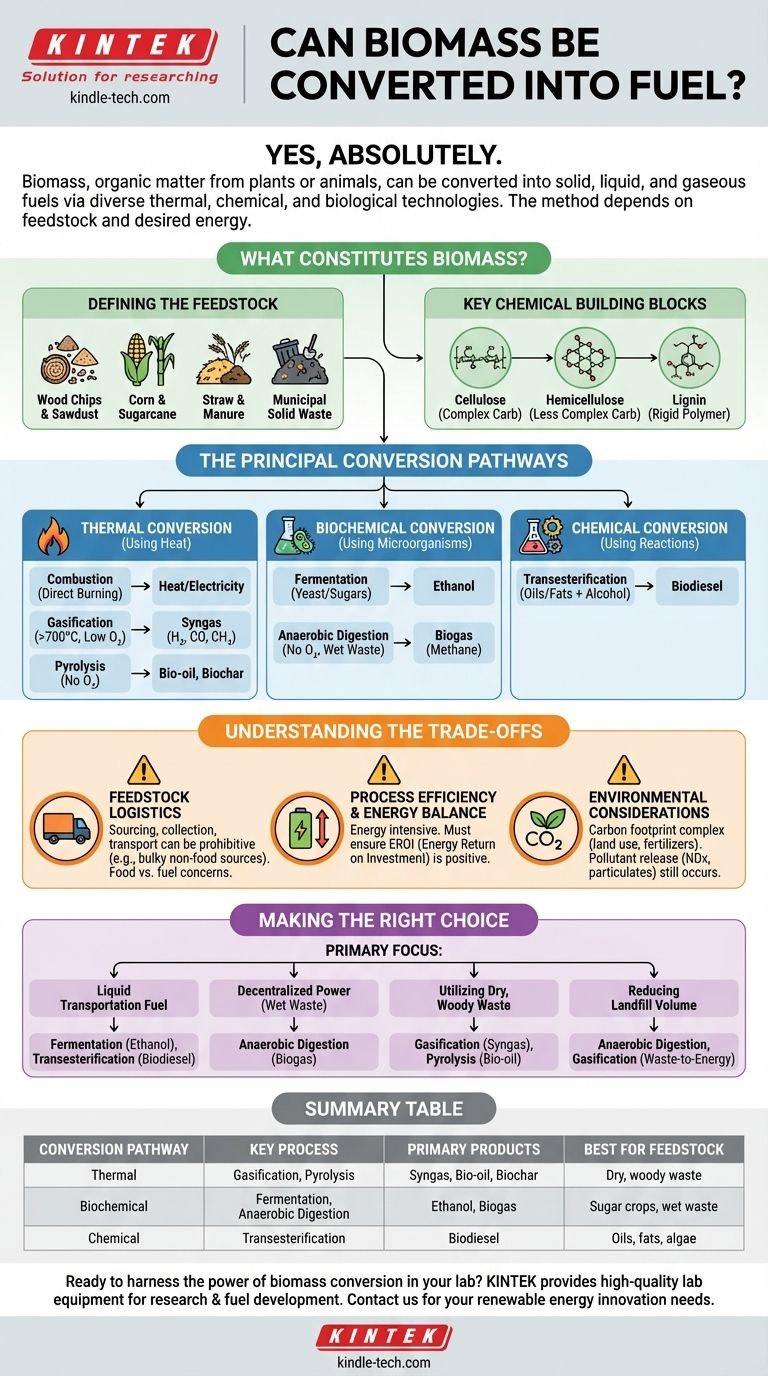

Yes, absolutely. Biomass, which is any organic matter from plants or animals, can be converted into a wide range of solid, liquid, and gaseous fuels. These biofuels can be used for transportation, heating, and electricity generation through several well-established thermal, chemical, and biological pathways.

Converting biomass into fuel is not a single process, but a diverse set of technologies. The most effective method depends entirely on the type of organic material you start with (the feedstock) and the specific type of energy you need to produce.

What Constitutes "Biomass"?

To understand how to convert it, we must first define what we are working with. Biomass is a broad term for a complex group of materials.

Defining the Feedstock

Biomass includes a vast array of organic materials. This ranges from forestry products like wood chips and sawdust to agricultural crops like corn and sugarcane. It also includes agricultural residues like straw, animal manure, and even the organic portion of municipal solid waste.

The Key Chemical Building Blocks

At a chemical level, most plant-based biomass is composed of three primary components:

- Cellulose: A complex carbohydrate that forms the main structure of plant cell walls.

- Hemicellulose: A less complex carbohydrate that surrounds the cellulose fibers.

- Lignin: A rigid organic polymer that binds cellulose and hemicellulose together, giving wood its strength.

The ratio of these components heavily influences which conversion process is most suitable.

The Principal Conversion Pathways

There are three main families of technologies used to transform raw biomass into usable fuel. Each works on a different principle and yields different products.

Thermal Conversion (Using Heat)

These methods use high temperatures to break down the biomass.

- Combustion: This is the simplest method—direct burning of biomass in the presence of oxygen. It releases heat that can be used to boil water, create steam, and turn turbines to generate electricity.

- Gasification: This process heats biomass to high temperatures (>700°C) with a very limited amount of oxygen. Instead of burning, the biomass converts into a mixture called syngas, composed primarily of hydrogen, carbon monoxide, and methane. Syngas can be burned for power or refined into liquid fuels.

- Pyrolysis: This involves heating biomass in the complete absence of oxygen. It produces a liquid known as bio-oil (or pyrolysis oil), a solid charcoal-like substance called biochar, and a synthetic gas. Bio-oil can be upgraded into transportation fuels.

Biochemical Conversion (Using Microorganisms)

These methods leverage natural biological processes to break down biomass.

- Fermentation: This is the same process used to make alcoholic beverages. Microbes, typically yeast, consume simple sugars found in crops like corn and sugarcane and convert them into ethanol, a common alcohol fuel.

- Anaerobic Digestion: In the absence of oxygen, different types of microbes break down wet organic matter like manure or food waste. This process produces biogas, which is mostly methane and can be used for heating or electricity generation.

Chemical Conversion (Using Chemical Reactions)

This category involves chemical reactions to convert specific components of biomass.

- Transesterification: This is the primary process used to make biodiesel. It takes oils and fats—from sources like vegetable oil, animal fat, or algae—and reacts them with an alcohol (like methanol) in the presence of a catalyst. The reaction creates biodiesel and a glycerol byproduct.

Understanding the Trade-offs

While biomass is a promising renewable resource, its conversion to fuel is not without significant challenges and considerations.

Feedstock Sourcing and Logistics

The type of biomass matters immensely. First-generation biofuels from food crops (like corn ethanol) raise concerns about competition with the food supply and land use.

Second- and third-generation biofuels focus on non-food sources like grasses, wood waste, and algae, but collecting, drying, and transporting this bulky material to a processing facility can be economically prohibitive.

Process Efficiency and Energy Balance

Some conversion processes are energy-intensive. If it takes more energy to grow, harvest, transport, and convert the biomass than the resulting fuel provides, the process is not sustainable. This "Energy Return on Investment" (EROI) is a critical metric.

Environmental Considerations

While often called "carbon neutral," the true carbon footprint of biofuels is complex. Factors like deforestation for crop planting, fertilizer use, water consumption, and energy used during conversion must be accounted for.

Furthermore, burning any fuel, including biofuels, still releases pollutants like nitrogen oxides and particulates, though often at different levels than fossil fuels.

Making the Right Choice for Your Goal

The best biomass conversion strategy is directly tied to your available resources and desired outcome.

- If your primary focus is liquid transportation fuel: Fermentation to produce ethanol from sugar/starch crops and transesterification to produce biodiesel from oils are the most mature technologies.

- If your primary focus is decentralized power from wet waste: Anaerobic digestion is an excellent choice for farms, wastewater treatment plants, or communities to convert manure and food waste into biogas for heat and electricity.

- If your primary focus is utilizing dry, woody waste: Gasification to produce syngas for power generation or pyrolysis to create bio-oil and biochar are the leading thermal options.

- If your primary focus is reducing landfill volume: Both anaerobic digestion (for organic waste) and thermal processes like gasification (for mixed solid waste) are powerful waste-to-energy solutions.

Understanding these distinct pathways and their associated trade-offs is the first step toward effectively harnessing the energy stored within organic matter.

Summary Table:

| Conversion Pathway | Key Process | Primary Products | Best For Feedstock |

|---|---|---|---|

| Thermal | Gasification, Pyrolysis | Syngas, Bio-oil, Biochar | Dry, woody waste |

| Biochemical | Fermentation, Anaerobic Digestion | Ethanol, Biogas | Sugar crops, wet waste |

| Chemical | Transesterification | Biodiesel | Oils, fats, algae |

Ready to harness the power of biomass conversion in your lab? KINTEK specializes in providing high-quality lab equipment and consumables essential for biomass research and biofuel development. Whether you're analyzing feedstock, optimizing conversion processes, or testing fuel quality, our reliable tools help you achieve accurate and efficient results. Contact us today to discuss how we can support your laboratory's specific needs in renewable energy innovation.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products