Pyrolysis of scrap tires can indeed be profitable, provided that certain conditions are met. The process involves breaking down the tires at high temperatures in the absence of oxygen, resulting in the production of valuable by-products such as oil, gas, and carbon black. These by-products can be sold or used as fuel, reducing operational costs. Additionally, pyrolysis helps in the degradation of toxic components and pathogens, reduces water volume, and limits the need for external fuel by utilizing the gases produced during the process. However, profitability depends on factors such as the scale of operation, market demand for by-products, initial investment, and operational efficiency.

Key Points Explained:

-

By-Products and Their Market Value:

- Oil: The oil produced from pyrolysis can be used as a fuel or further refined into higher-value products. Its market value depends on the quality and the prevailing market prices for crude oil.

- Gas: The gases produced, such as methane and hydrogen, can be used to power the pyrolysis process itself, reducing the need for external fuel and lowering operational costs.

- Carbon Black: This is a valuable material used in the manufacture of tires, inks, and other industrial products. The quality and market demand for carbon black can significantly impact profitability.

-

Operational Efficiency:

- Scale of Operation: Larger-scale operations tend to be more profitable due to economies of scale. The initial investment is high, but the cost per unit of output decreases as the scale increases.

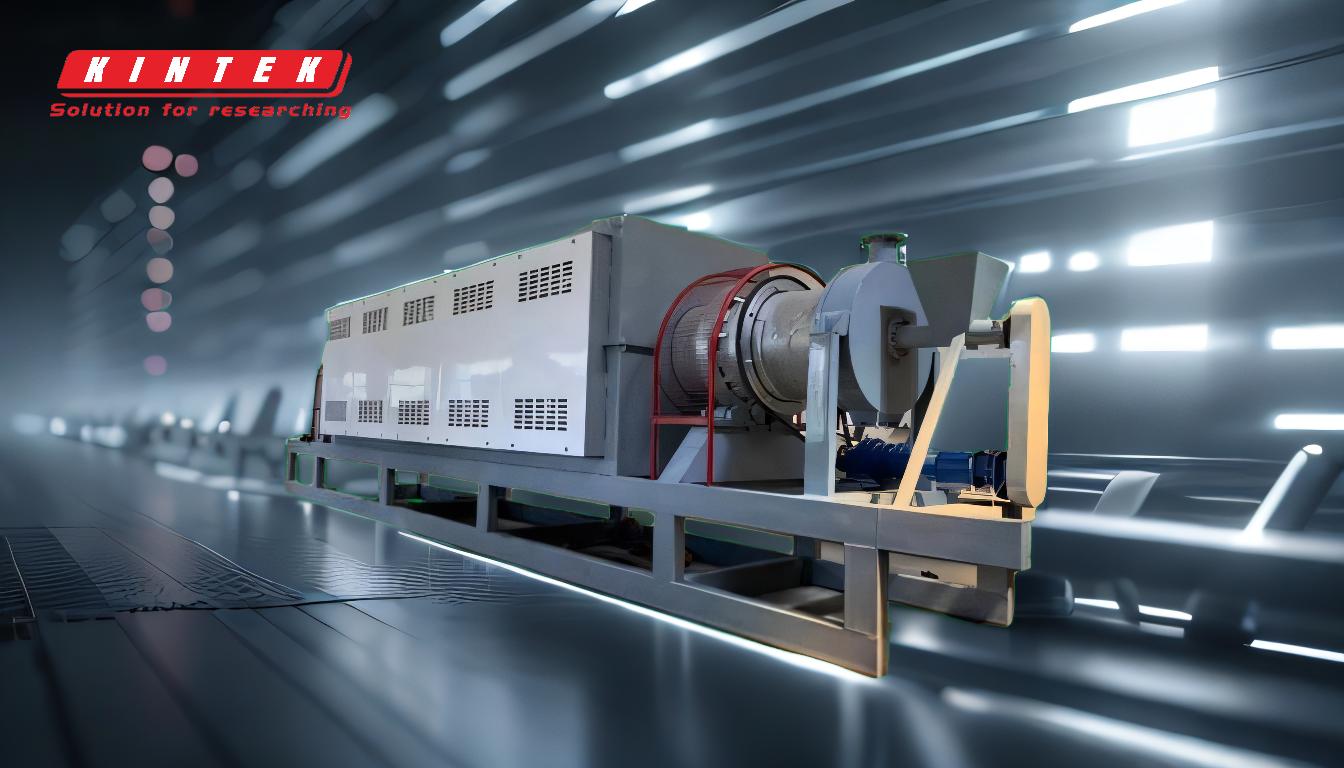

- Technology and Equipment: Advanced pyrolysis technology can improve yield and reduce waste, enhancing profitability. Investing in high-quality equipment can lead to more efficient operations and higher-quality by-products.

-

Environmental and Regulatory Considerations:

- Compliance: Adhering to environmental regulations can incur costs, but it also opens up opportunities for subsidies and incentives for waste management and recycling projects.

- Public Perception: Companies that engage in environmentally friendly practices can benefit from positive public perception, potentially leading to increased market share and higher prices for their by-products.

-

Market Demand and Competition:

- Demand for By-Products: The profitability of pyrolysis is heavily dependent on the market demand for its by-products. Fluctuations in the prices of oil, gas, and carbon black can impact revenue.

- Competition: The presence of competitors can drive down prices, but it can also stimulate innovation and efficiency improvements.

-

Initial Investment and Financing:

- Capital Costs: The initial investment required for setting up a pyrolysis plant can be substantial. Securing financing at favorable terms is crucial for ensuring profitability.

- Operational Costs: Ongoing costs include labor, maintenance, and raw material procurement. Efficient management of these costs is essential for maintaining profitability.

-

Risk Management:

- Market Risks: Fluctuations in the prices of by-products and raw materials can pose risks. Diversifying the product portfolio and securing long-term contracts can mitigate these risks.

- Operational Risks: Equipment failure and process inefficiencies can lead to downtime and increased costs. Regular maintenance and process optimization are key to minimizing these risks.

In conclusion, while pyrolysis of scrap tires has the potential to be profitable, it requires careful planning, efficient operation, and a thorough understanding of market dynamics. By focusing on the quality and marketability of by-products, optimizing operational efficiency, and managing risks, businesses can enhance their chances of achieving profitability in this sector.

Summary Table:

| Key Factor | Impact on Profitability |

|---|---|

| By-Products | Oil, gas, and carbon black can be sold or used as fuel, reducing costs and increasing revenue. |

| Operational Efficiency | Larger scale and advanced technology improve yield and reduce costs. |

| Market Demand | Fluctuating prices of by-products and competition influence profitability. |

| Initial Investment | High capital costs require favorable financing terms to ensure profitability. |

| Environmental Compliance | Adhering to regulations can lead to subsidies and positive public perception. |

| Risk Management | Diversifying products and optimizing processes mitigate market and operational risks. |

Ready to explore the profitability of pyrolysis for your business? Contact us today to learn more!