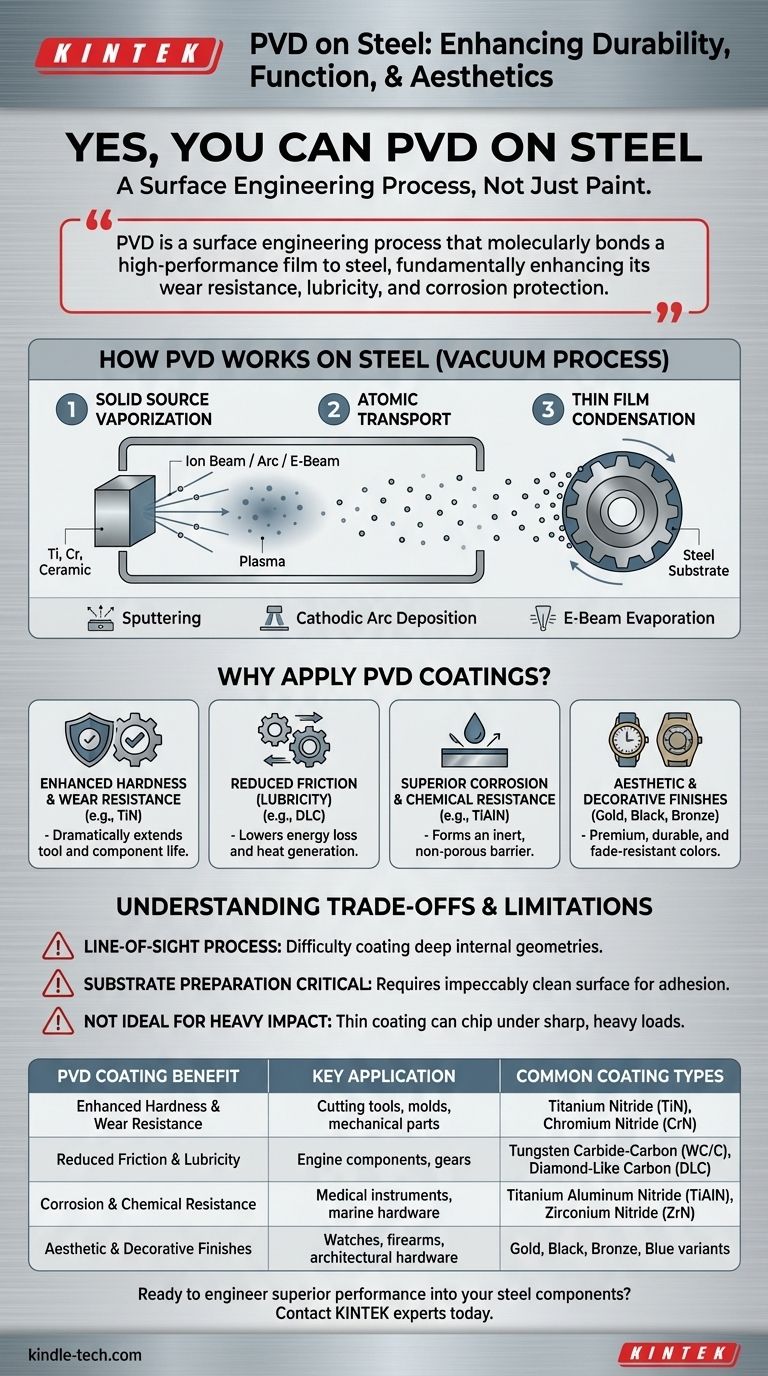

Yes, you can absolutely apply PVD coatings to steel. In fact, steel is one of the most common and ideal substrates for the Physical Vapor Deposition (PVD) process. This technique is widely used to deposit a thin, bonded film of metal or ceramic onto steel surfaces, fundamentally enhancing their durability, function, and appearance for countless industrial and consumer applications.

While the answer is a definitive yes, the more critical understanding is that PVD is not merely a paint. It is a surface engineering process that molecularly bonds a high-performance film to steel, fundamentally enhancing its wear resistance, lubricity, and corrosion protection.

What is PVD and How Does It Work on Steel?

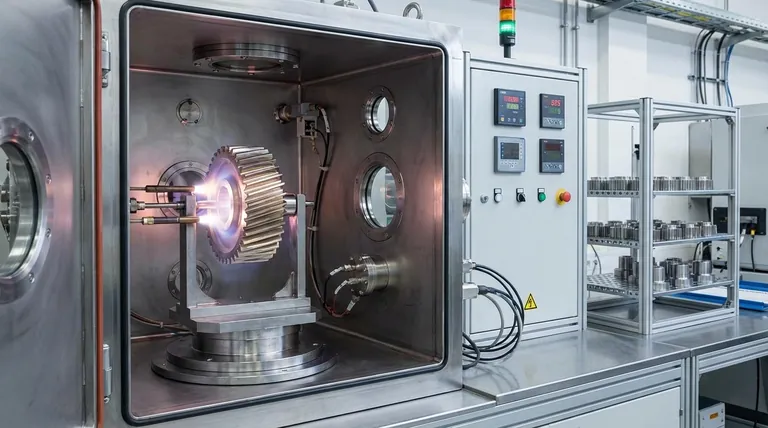

Physical Vapor Deposition is a group of vacuum-based processes used to create a very thin, yet extremely durable, coating on a substrate. The entire process takes place within a high-vacuum chamber to ensure purity and prevent unwanted chemical reactions.

The Core Principle: Atomic Deposition

Think of PVD as a form of atomic-level spray painting. First, a solid source material—such as titanium, chromium, or a specialized ceramic—is vaporized into a plasma or gas inside the vacuum chamber.

These vaporized atoms are then transported across the chamber and condense onto the steel parts, forming a thin, dense, and highly-adherent film on the surface.

From Solid Source to Thin Film

The process transforms a solid material into a vapor and then back into a solid film, all without ever entering a liquid state. This allows for precise control over the coating's thickness, structure, and properties, which are monitored in real-time.

Key PVD Methods Used for Steel

While PVD is a general term, several specific methods are commonly used for coating steel, each with unique advantages.

- Sputtering: An ion beam bombards the source material, "sputtering" atoms off, which then deposit onto the steel. This method offers excellent uniformity.

- Cathodic Arc Deposition: A high-current electric arc moves across the source material, vaporizing it into a highly ionized plasma. This creates exceptionally dense and hard coatings, ideal for cutting tools.

- Electron Beam (E-Beam) Evaporation: A focused beam of electrons heats and vaporizes the source material. It allows for very high deposition rates.

Why Apply PVD Coatings to Steel Parts?

Engineers and designers choose to PVD coat steel not just to cover it, but to impart new and superior properties to the component's surface.

Enhanced Hardness and Wear Resistance

PVD ceramic coatings, like Titanium Nitride (TiN), are significantly harder than any steel. This creates a surface that is highly resistant to abrasion, erosion, and wear, dramatically extending the life of cutting tools, molds, and mechanical components.

Reduced Friction (Increased Lubricity)

Certain PVD coatings have a very low coefficient of friction. Applying them to moving steel parts, such as engine components or gears, reduces energy loss, minimizes heat generation, and can allow for operation with less lubrication.

Superior Corrosion and Chemical Resistance

The deposited film is fully dense and non-porous, creating an inert barrier between the steel substrate and its environment. This provides outstanding protection against rust, oxidation, and attack from various chemicals.

Aesthetic and Decorative Finishes

PVD coatings can be produced in a wide variety of colors (gold, black, bronze, blue, etc.) with a premium, metallic finish. Unlike paint or traditional plating, these colors are extremely durable and resistant to fading, tarnishing, and scratching, making them ideal for watches, hardware, and firearms.

Understanding the Trade-offs and Limitations

While powerful, PVD is not a universal solution. Understanding its limitations is key to using it effectively.

It's a Line-of-Sight Process

Because the vaporized material travels in a straight line, PVD has difficulty coating the inside of deep, narrow bores or complex internal geometries. Parts must often be rotated on complex fixtures to ensure even coverage on all exposed surfaces.

Substrate Preparation is Critical

The final coating is only as good as the surface underneath it. The steel part must be impeccably clean and have a smooth, consistent surface finish. Any contamination, oil, or surface imperfection will result in poor adhesion and potential coating failure.

Not Ideal for Heavy Impact

PVD coatings are extremely hard but also very thin (typically a few microns). While they excel against abrasive wear, they can be chipped or fractured by a sharp, heavy impact. The underlying toughness of the steel substrate remains the limiting factor for impact resistance.

Making the Right Choice for Your Steel Application

Choosing PVD is about matching the technology's strengths to your specific goal.

- If your primary focus is maximizing wear resistance for tools or components: PVD provides an exceptionally hard surface layer that can dramatically extend the life of the part.

- If your primary focus is combining corrosion protection with a premium decorative finish: PVD offers a durable, tarnish-resistant coating in a wide range of colors that is far superior to traditional plating or paint.

- If your primary focus is reducing friction in moving assemblies: Specific PVD coatings are engineered for a low coefficient of friction, improving efficiency and reducing wear.

Ultimately, PVD coating allows you to transform a standard steel surface into a high-performance material engineered for a specific purpose.

Summary Table:

| PVD Coating Benefit | Key Application | Common Coating Types |

|---|---|---|

| Enhanced Hardness & Wear Resistance | Cutting tools, molds, mechanical parts | Titanium Nitride (TiN), Chromium Nitride (CrN) |

| Reduced Friction & Lubricity | Engine components, gears | Tungsten Carbide-Carbon (WC/C), Diamond-Like Carbon (DLC) |

| Corrosion & Chemical Resistance | Medical instruments, marine hardware | Titanium Aluminum Nitride (TiAlN), Zirconium Nitride (ZrN) |

| Aesthetic & Decorative Finishes | Watches, firearms, architectural hardware | Gold, Black, Bronze, Blue variants |

Ready to engineer superior performance into your steel components? KINTEK specializes in advanced PVD coating solutions for laboratory and industrial equipment. Our expertise ensures your steel parts gain maximum durability, reduced friction, and lasting aesthetic appeal. Contact our experts today to discuss how our PVD coatings can transform your products!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What is hot press forging? Creating Complex, High-Strength Metal Components

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts

- What is the main function of hot press forming? Achieve Superior Strength & Precision in Manufacturing