Yes, sintering time critically affects the marginal fit of zirconia copings. The duration of the sintering cycle directly governs the material's final shrinkage. If the time is too short or too long relative to the manufacturer's validated protocol, the restoration will not shrink to the precise dimensions anticipated by the design software, resulting in a compromised marginal fit.

The core issue is not time itself, but the consistency between the sintering cycle used and the specific material's requirements. Any deviation from the zirconia manufacturer's validated protocol—whether shortening or lengthening the time—introduces a high risk of dimensional inaccuracy that directly compromises the final fit.

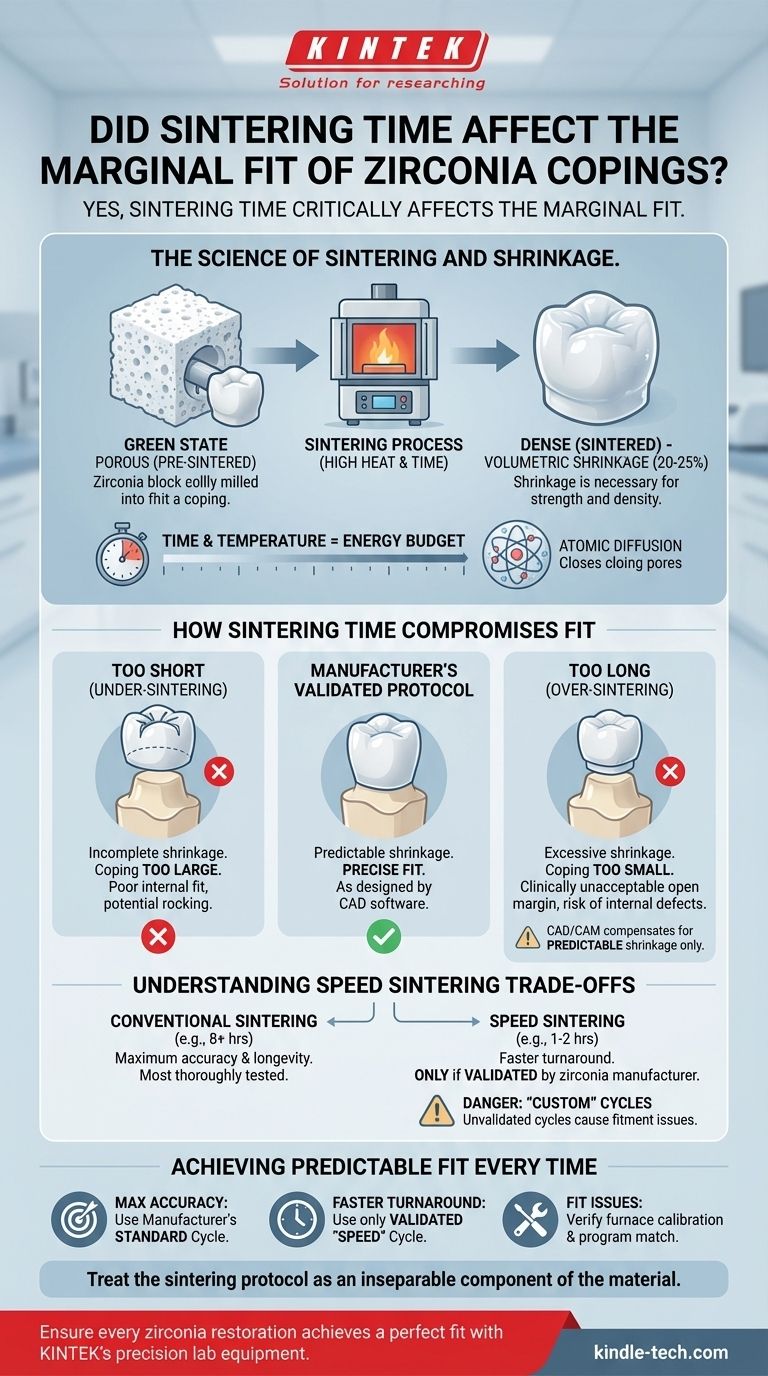

The Science of Sintering and Shrinkage

To understand how time impacts fit, we must first understand the fundamental transformation that occurs during sintering.

From Porous to Dense

A zirconia coping is first milled from a pre-sintered, chalk-like block. In this "green state," it is porous and relatively weak. To achieve its final strength, it must be sintered in a high-temperature furnace.

This process eliminates porosity and dramatically increases the material's density. The result is a hard, strong restoration suitable for the demanding environment of the oral cavity.

Why Shrinkage Is Necessary

This increase in density is achieved through volumetric shrinkage, which can be as much as 20-25%. During sintering, the individual zirconia particles fuse together, closing the gaps and pores between them.

This shrinkage is not a defect; it is an essential and planned part of the manufacturing process that gives zirconia its exceptional strength.

The Role of Time and Temperature

Sintering is a process of atomic diffusion that requires a specific amount of energy (heat) applied over a specific duration (time). The manufacturer’s instructions create a precise "energy budget" to achieve complete and uniform densification without causing material degradation.

How Sintering Time Compromises Fit

The entire CAD/CAM process is built around compensating for this predictable shrinkage. The problem arises when the actual shrinkage deviates from the plan.

The Digital Compensation Factor

When a restoration is designed, the CAD software automatically enlarges the dimensions based on a known shrinkage factor. This factor is provided by the zirconia manufacturer and is only accurate if their specific, validated sintering cycle is followed precisely.

The Risk of Under-Sintering (Cycle Too Short)

If the sintering time is cut short, the material does not have enough time to complete its diffusion process. Shrinkage will be incomplete.

The resulting coping will be too large. While this may not always produce a visible open margin, the internal fit will be poor, potentially leading to a rocking restoration and a thicker, weaker cement layer.

The Risk of Over-Sintering (Cycle Too Long)

If the sintering time is too long, the material can effectively over-shrink, making the coping too small. This will prevent it from seating completely on the die, creating a clinically unacceptable open margin.

Furthermore, excessive time at high temperatures can lead to abnormal grain growth. As seen in other advanced ceramics, this can create internal defects and paradoxically decrease the material's hardness and fracture resistance.

Understanding the Trade-offs: Speed vs. Accuracy

The demand for faster turnaround has led to the development of "speed sintering" cycles, creating a critical decision point for dental laboratories.

The Appeal of "Speed Sintering"

Conventional sintering cycles can take 8 hours or more. Speed sintering cycles promise a similar outcome in a fraction of that time, sometimes as little as 1-2 hours, significantly improving lab efficiency.

The Non-Negotiable Requirement

These accelerated cycles are only viable if they have been specifically developed and validated by the zirconia manufacturer for that exact material. Manufacturers achieve this by adjusting temperature profiles to deliver the required energy in a shorter window.

The Danger of "Custom" Cycles

Never use a speed sintering cycle from one brand of furnace or zirconia on a different material. The compensation factor in the software is calibrated for a specific time-and-temperature protocol. Using an unvalidated cycle is the primary cause of fitment issues, as the actual shrinkage will not match the predicted shrinkage.

Achieving Predictable Fit Every Time

Your approach to sintering should be dictated by your clinical and business priorities, but it must always be guided by the manufacturer's science.

- If your primary focus is maximum accuracy and longevity: Use the manufacturer's standard, conventional sintering cycle, as this protocol is the most thoroughly tested and reliable.

- If your primary focus is reducing turnaround time: Only use a "speed" or "fast" sintering cycle that is explicitly approved and validated by the manufacturer for the specific zirconia you are using.

- If you are experiencing fit issues: First, verify your furnace is calibrated. Then, confirm that the selected sintering program exactly matches the zirconia manufacturer's instructions for that specific material batch.

By treating the sintering protocol as an inseparable component of the material itself, you can ensure consistent, precise results and eliminate fit-related failures.

Summary Table:

| Sintering Time Effect | Impact on Zirconia Coping | Result on Marginal Fit |

|---|---|---|

| Too Short (Under-Sintering) | Incomplete shrinkage | Coping too large; poor internal fit |

| Too Long (Over-Sintering) | Excessive shrinkage | Coping too small; open margin |

| Manufacturer's Protocol | Predictable shrinkage | Precise fit as designed |

Ensure every zirconia restoration achieves a perfect fit with KINTEK's precision lab equipment.

As a leading provider of laboratory equipment and consumables, KINTEK understands that consistent, accurate sintering is non-negotiable for dental labs. Our reliable sintering furnaces are designed to deliver the precise temperature control and cycle consistency required to adhere to zirconia manufacturers' protocols, eliminating fit-related failures.

We help you:

- Achieve predictable shrinkage and perfect marginal fit for every coping.

- Increase lab efficiency without compromising on restoration quality.

- Eliminate costly remakes due to dimensional inaccuracies.

Ready to optimize your sintering process and ensure flawless results? Contact our experts today to find the ideal furnace for your laboratory's needs and materials.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics