Yes, absolutely. A diamond created through Chemical Vapor Deposition (CVD) is chemically, physically, and optically identical to a mined diamond. Therefore, it will pass all standard tests designed to confirm a stone is a genuine diamond by measuring its thermal and electrical conductivity.

The question is not whether a CVD diamond is "real"—it is. The critical distinction is its origin: one is grown in a lab, and the other is extracted from the earth. Both are structurally identical diamonds, and standard testers cannot tell them apart.

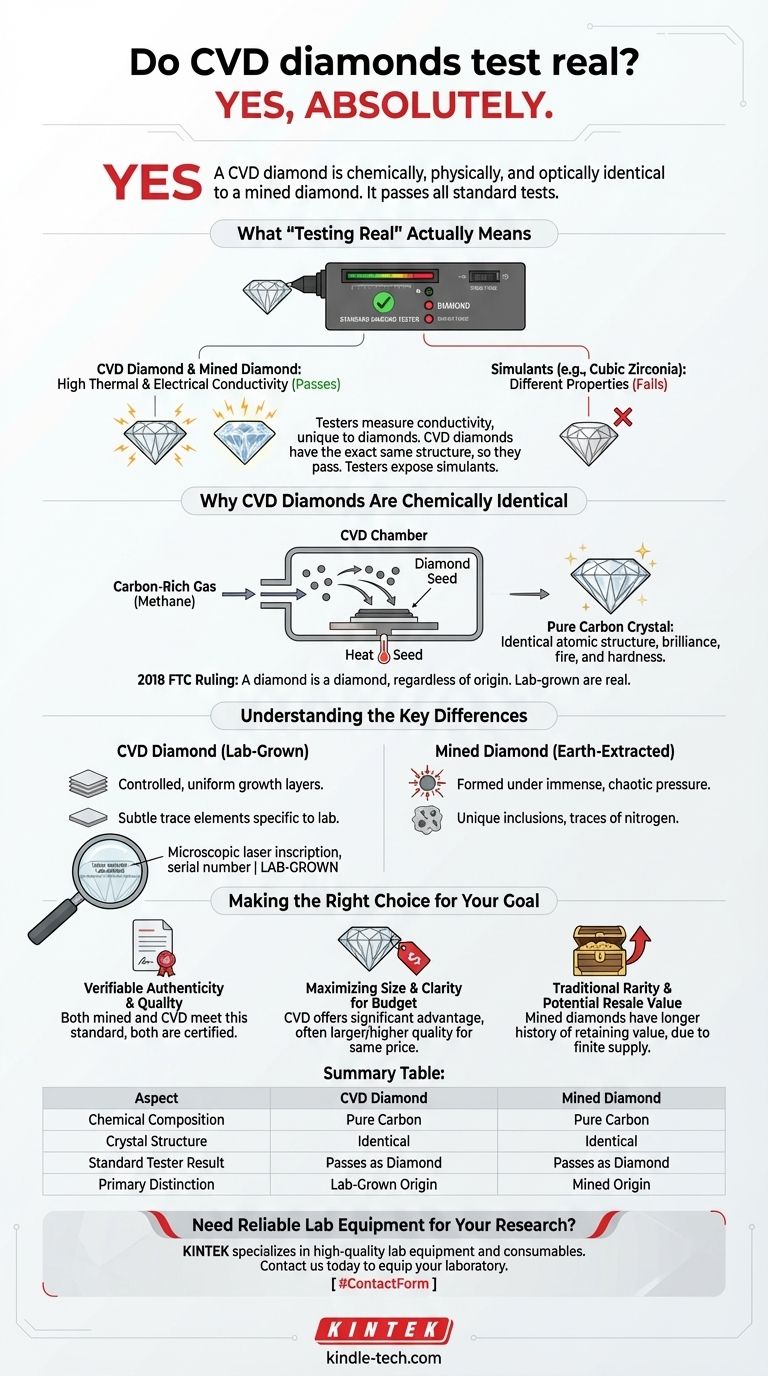

What "Testing Real" Actually Means

To understand why CVD diamonds pass, you must first understand what a standard diamond tester is designed to detect. Its purpose is not to distinguish a lab-grown diamond from a mined one.

The Standard Diamond Tester

Most jewelers use a handheld device that measures how quickly heat or electricity moves through a stone. This property, known as thermal and electrical conductivity, is exceptionally high and unique in diamonds.

Because a CVD diamond is made of pure carbon organized in the same crystal lattice structure as a mined diamond, it has the exact same conductive properties. The tester correctly identifies it as a diamond.

The "Fake Diamond" Distinction

These testers are built to expose simulants—stones that look like diamonds but have a different chemical makeup. This includes materials like cubic zirconia, moissanite, or glass.

These imitations have different thermal and electrical properties and will fail the test, immediately identifying them as "not a diamond."

Why CVD Diamonds Are Chemically Identical

The term "lab-grown" can be misleading. It does not mean "imitation." The process simply replicates the natural diamond-forming environment in a controlled setting.

The CVD Creation Process

CVD stands for Chemical Vapor Deposition. The process begins with a small, flat diamond "seed." This seed is placed into a vacuum chamber filled with carbon-rich gases (like methane).

When heated to high temperatures, these gases break down, and the carbon atoms deposit onto the diamond seed, growing a new diamond layer by layer.

The Result: A Pure Carbon Crystal

The final product is not a look-alike; it is a genuine diamond. It has the same atomic structure, brilliance, fire, and hardness as one formed deep within the Earth.

In 2018, the U.S. Federal Trade Commission (FTC) amended its Jewelry Guides to state that a diamond is a diamond, regardless of its origin. This ruling officially classifies lab-grown diamonds as real diamonds.

Understanding the Key Differences

While a standard tester sees no difference, specialized gemological laboratories can distinguish between a CVD and a mined diamond. The distinction lies in their growth patterns and trace elements, not in their core identity.

Growth Structure and Inclusions

Mined diamonds form under immense, chaotic pressure, resulting in unique internal characteristics and often containing traces of nitrogen.

CVD diamonds grow in controlled, uniform layers. This can result in different growth patterns and, while they typically lack nitrogen, may contain other trace elements specific to the lab environment. These subtle clues are only detectable with advanced scientific equipment.

Microscopic Laser Inscriptions

As a measure of transparency, reputable producers of CVD diamonds often laser-inscribe a unique serial number on the stone's girdle.

This inscription is invisible to the naked eye but confirms the diamond's origin as lab-created. This is not a mark of inferiority but a commitment to clear disclosure.

Making the Right Choice for Your Goal

Ultimately, the choice between a mined and a CVD diamond is a matter of personal priorities. Both are authentic diamonds that will pass standard tests.

- If your primary focus is verifiable authenticity and quality: Both mined and CVD diamonds meet this standard, as both are structurally identical and certified.

- If your primary focus is maximizing size and clarity for your budget: CVD diamonds offer a significant advantage, often providing a larger, higher-quality stone for the same price as a smaller mined diamond.

- If your primary focus is traditional rarity and potential resale value: Mined diamonds, due to their finite supply, have a longer history of retaining value, though all diamond markets are subject to fluctuation.

Your decision should be based on an informed understanding of what matters most to you, not a simple label of "mined" versus "lab-grown."

Summary Table:

| Aspect | CVD Diamond | Mined Diamond |

|---|---|---|

| Chemical Composition | Pure Carbon | Pure Carbon |

| Crystal Structure | Identical | Identical |

| Standard Tester Result | Passes as Diamond | Passes as Diamond |

| Primary Distinction | Lab-Grown Origin | Mined Origin |

Need Reliable Lab Equipment for Your Research?

Understanding the precise properties of materials like CVD diamonds requires accurate and dependable laboratory equipment. At KINTEK, we specialize in supplying high-quality lab equipment and consumables to support your research and quality control processes.

Whether you are developing new materials or verifying the properties of gemstones, our products are designed to deliver the precision and reliability you need.

Contact us today using the form below to discuss how KINTEK can equip your laboratory for success.

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What are the applications of thin-film in renewable energy? Beyond Solar Panels to Energy Storage & Hydrogen

- What are sputtering targets made of? From Pure Metals to Ceramics for Your Thin Film

- What are the advantages of chemical bath deposition? A Low-Cost, Scalable Thin Film Solution

- What are some common materials synthesized using CVD? Explore Nanostructures, Coatings, and High-Purity Films

- What is the process of thin film making? A Guide to Controlled Deposition Techniques

- How are carbon nanotubes conductive? Unlocking Their Metallic or Semiconducting Nature

- What is the effect of thickness of thin film? Master Optical, Electrical, and Mechanical Properties

- What are the categories of carbon nanotubes? Understand SWCNT vs. MWCNT for Your Application