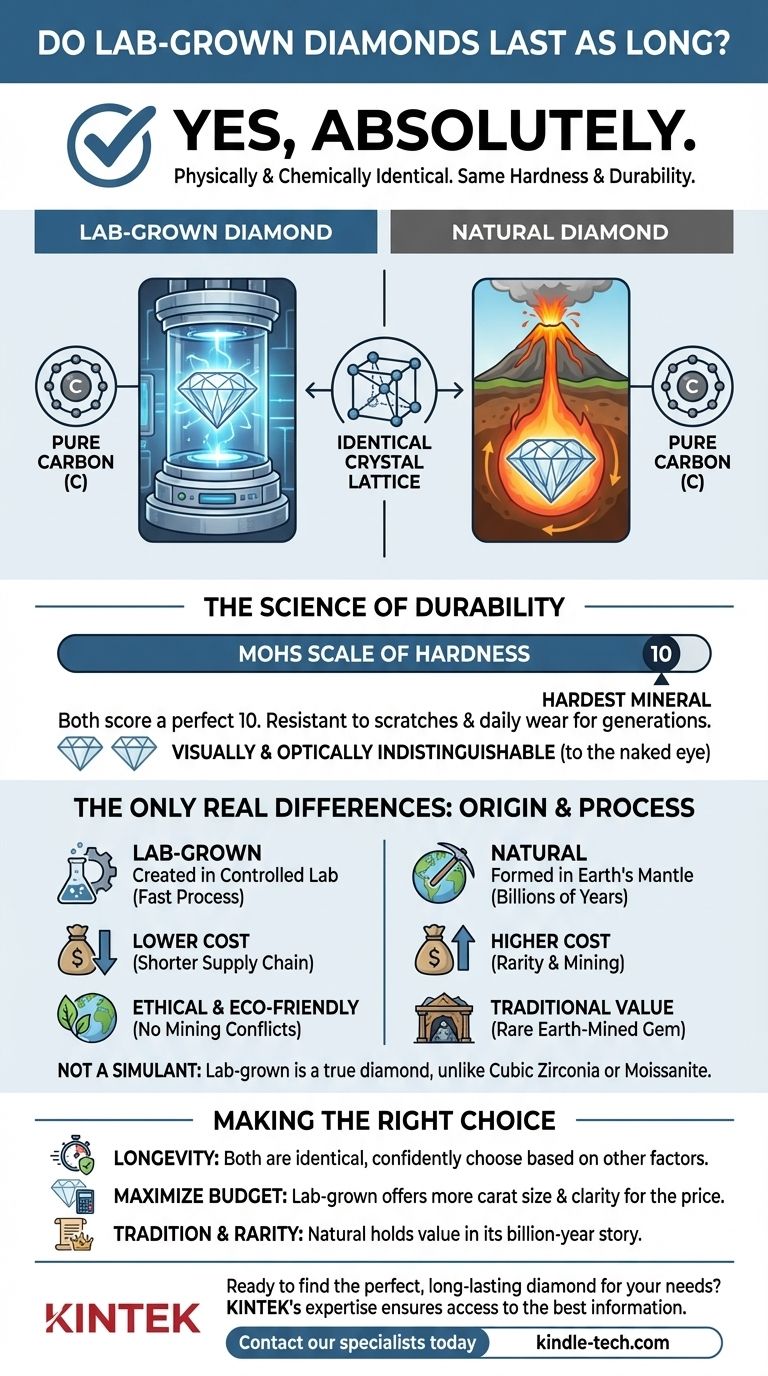

Yes, absolutely. Lab-grown diamonds last just as long as natural diamonds because they are physically and chemically identical. Both are composed of pure carbon atoms arranged in the same crystal lattice structure, giving them the exact same hardness and durability. The only difference between them is their origin.

The core takeaway is that a diamond's longevity is determined by its chemical structure and hardness, not its origin. Since lab-grown and natural diamonds are identical in these fundamental properties, their durability and lifespan are also identical.

What Determines a Diamond's Durability?

To understand why a lab-grown diamond is just as durable as a natural one, it's essential to look at what makes a diamond last in the first place.

The Identical Chemical Composition

Both natural and lab-grown diamonds are made of pure carbon. Their atoms are bonded together in an incredibly strong and rigid crystal structure.

This atomic arrangement is what defines the material as a "diamond." It’s not about where it was formed, but what it's made of and how it's structured.

The Unmatched Hardness

A material's ability to resist scratches and abrasions—its hardness—is a key factor in its longevity.

Because they share the same crystal structure, both lab-grown and natural diamonds score a perfect 10 on the Mohs scale of hardness. This makes them the hardest known natural mineral, capable of withstanding daily wear for generations.

Lab-Grown vs. Natural: The Only Real Difference

The distinction between these two types of diamonds is not one of substance, but of story and process.

A Matter of Origin, Not Material

Natural diamonds are formed deep within the Earth's mantle over billions of years under immense heat and pressure, brought to the surface by volcanic eruptions.

Lab-grown diamonds are created using technology that replicates these exact conditions in a highly controlled laboratory setting. The process is much faster, but the final product is the same.

Indistinguishable to the Naked Eye

The two are visually, physically, and optically identical. Without specialized gemological equipment, even a trained expert cannot tell them apart.

A Potential for Higher Purity

Because they are grown in a sterile, controlled environment, lab-grown diamonds often have fewer inclusions or internal blemishes than their natural counterparts. This means you can often get a visually cleaner diamond.

Understanding the Trade-offs

Choosing between a lab-grown and natural diamond isn't about choosing a "better" or "worse" stone. It's about aligning your purchase with your personal values.

The Myth of the "Fake" Diamond

It is crucial to distinguish a lab-grown diamond from a diamond simulant. A simulant, like cubic zirconia or moissanite, looks like a diamond but has a different chemical composition and is far less durable.

A lab-grown diamond is not a simulant; it is a true diamond in every scientific sense.

The Primary Trade-off: Cost

The main advantage of lab-grown diamonds is their price. Because the supply chain is shorter and less resource-intensive, they typically cost significantly less than natural diamonds of the same size and quality.

Ethical and Environmental Factors

Lab-grown diamonds bypass the environmental and ethical concerns associated with traditional mining. For many buyers, this is a significant factor in their decision.

Making the Right Choice for Your Goal

Your final decision should be based on your priorities, not on any misconception about quality or durability.

- If your primary focus is longevity and durability: Understand that both options are identical, so your choice can confidently be based on other factors.

- If your primary focus is maximizing carat size and clarity for your budget: A lab-grown diamond is the clear choice, offering more for your money without sacrificing quality.

- If your primary focus is the tradition and rarity of an Earth-mined gem: A natural diamond, with its billion-year-old story, will hold more value for you.

Ultimately, choosing a lab-grown diamond is not a compromise on quality or lifespan, but a modern choice based on technology and personal values.

Summary Table:

| Feature | Lab-Grown Diamond | Natural Diamond |

|---|---|---|

| Chemical Composition | Pure Carbon | Pure Carbon |

| Crystal Structure | Identical | Identical |

| Mohs Hardness | 10 | 10 |

| Durability & Lifespan | Identical | Identical |

| Primary Distinction | Origin (Lab-Created) | Origin (Earth-Mined) |

Ready to find the perfect, long-lasting diamond for your needs? Whether you prioritize cutting-edge technology, ethical sourcing, or maximizing your budget, KINTEK's expertise in high-quality lab equipment and materials ensures you have access to the best information. Contact our specialists today to discuss your project and discover how we support your laboratory's success with precision and reliability.

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Optical Windows for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What is the growth rate of CVD diamond? Discover the Secret to High-Purity Lab-Grown Gems

- Do jewelers have lab-grown diamonds? Discover the Ethical & Affordable Diamond Alternative

- How does chemical vapor deposition work for diamonds? Grow Lab-Created Diamonds Layer by Layer

- What are the industrial uses of CVD diamond? Unlock Extreme Performance in Your Applications

- What is the use of CVD diamond? Unlock Superior Performance in Extreme Applications

- Are CVD diamonds fake? Discover the Truth About Lab-Grown Diamonds

- What is the process for CVD diamond? Building a Diamond Atom by Atom