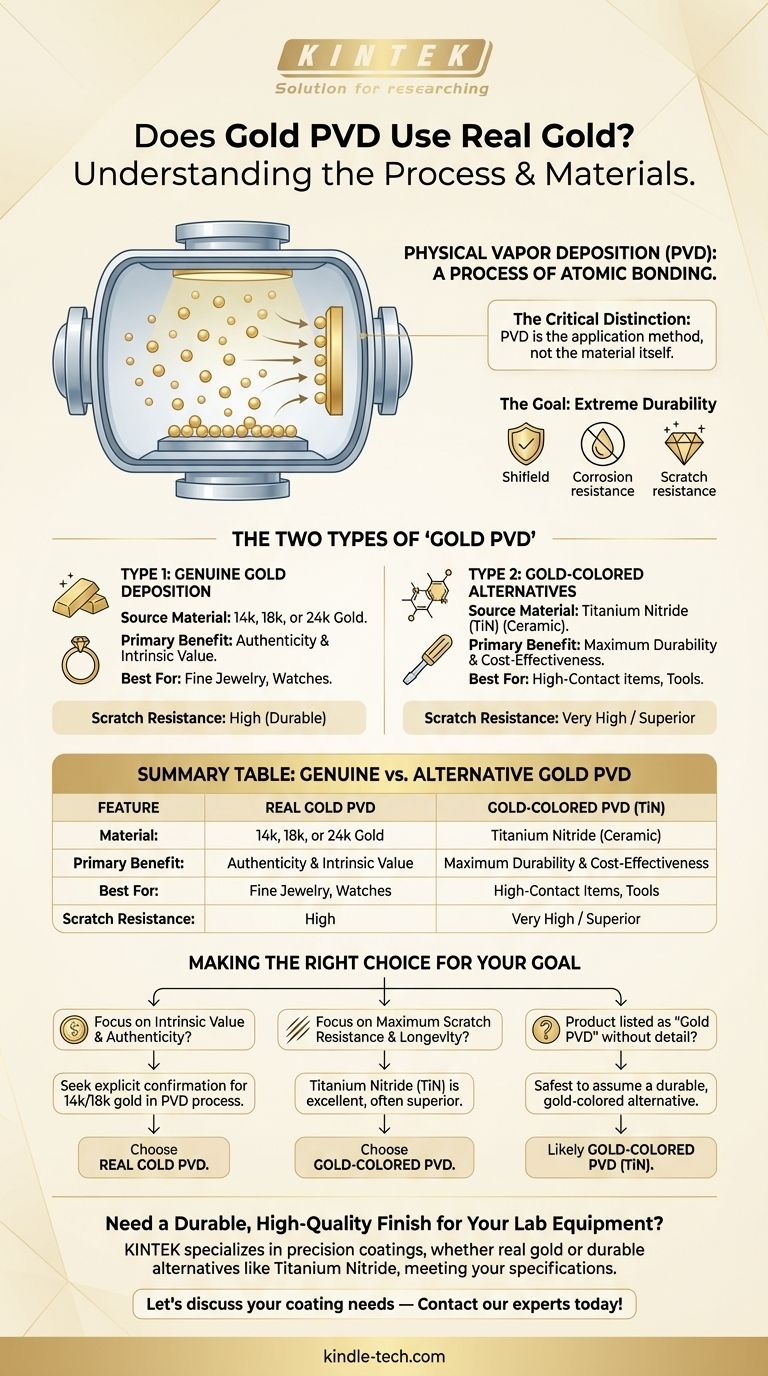

Yes, PVD coatings can use real gold, but they don't always. The term "gold PVD" refers to the Physical Vapor Deposition process used to create a gold-colored finish. That finish can be achieved by depositing a thin layer of genuine gold (like 14k or 18k) or by using a different, highly durable material like Titanium Nitride that has a gold-like appearance.

The critical distinction is that PVD is the application method, not the material itself. Understanding this difference is key to evaluating the quality, durability, and true value of a PVD-coated product.

What is PVD and Why Is It Used?

A Process of Atomic Bonding

Physical Vapor Deposition (PVD) is a high-tech vacuum coating process. Inside a vacuum chamber, a solid source material is vaporized into a plasma of atoms or molecules. This vapor is then deposited, atom by atom, onto the surface of the object being coated.

This method creates an incredibly thin, hard, and durable layer that is molecularly bonded to the base material.

The Goal: Extreme Durability

The primary advantage of PVD is not about applying gold, but about creating a finish that is vastly superior to traditional electroplating.

A PVD finish is exceptionally resistant to corrosion, tarnishing, and abrasion. It creates a protective barrier that is much harder and longer-lasting than a simple plated layer.

The Two Types of "Gold PVD"

Because PVD is a versatile process, the term "gold PVD" can describe two very different outcomes.

Type 1: Genuine Gold Deposition

In this application, real gold—often 14k, 18k, or even 24k—is the source material vaporized in the PVD chamber.

This process bonds a layer of genuine gold to the surface. You get the authentic color and intrinsic value of gold, combined with the superior adhesion and durability of the PVD method.

Type 2: Gold-Colored Alternatives

More commonly, a ceramic material like Titanium Nitride (TiN) is used as the source material. TiN is an extremely hard compound with a brilliant, gold-like color.

When applied via PVD, TiN creates a finish that is often even more scratch-resistant than a real gold PVD coating. It is used for its exceptional durability and lower cost while providing a near-identical aesthetic.

Understanding the Trade-offs

The lack of clarity in product descriptions is the main challenge. A manufacturer might simply say "gold PVD" without specifying the material used.

The Case for Real Gold PVD

The primary benefit here is authenticity. The product contains a layer of real, chemical gold. This is important for fine jewelry or watches where intrinsic value is a key factor.

The Case for Gold-Colored PVD (like TiN)

The benefits are maximum durability and cost-effectiveness. A Titanium Nitride coating is exceptionally hard and wear-resistant, making it ideal for high-contact items. For many applications, its performance surpasses that of a real gold PVD finish.

The Problem of Vague Marketing

Because PVD is seen as a premium feature, brands may not differentiate between using real gold or a gold-colored ceramic. If the material is not explicitly stated, it is often a durable alternative like TiN.

Making the Right Choice for Your Goal

To navigate this, you must determine what you value most in the product.

- If your primary focus is intrinsic value and authenticity: Seek explicit confirmation from the manufacturer that they use real 14k or 18k gold in their PVD process.

- If your primary focus is maximum scratch resistance and longevity: A finish using Titanium Nitride (TiN) or a similar ceramic is an excellent, and often superior, choice.

- If a product is simply listed as "gold PVD" without detail: It is safest to assume the finish is a durable, gold-colored alternative rather than genuine gold, especially if the price seems low.

Ultimately, PVD is a sign of a high-quality, durable finish, but it's your job to ask what material was used to achieve it.

Summary Table:

| Feature | Real Gold PVD | Gold-Colored PVD (e.g., TiN) |

|---|---|---|

| Material | 14k, 18k, or 24k Gold | Titanium Nitride (Ceramic) |

| Primary Benefit | Authenticity & Intrinsic Value | Maximum Durability & Cost-Effectiveness |

| Best For | Fine Jewelry, Watches | High-Contact Items, Tools |

| Scratch Resistance | High | Very High / Superior |

Need a Durable, High-Quality Finish for Your Lab Equipment or Components?

At KINTEK, we specialize in precision coatings for laboratory equipment and consumables. Whether your project requires the authenticity of real gold PVD or the extreme durability of ceramic alternatives like Titanium Nitride, our expertise ensures a finish that meets your exact specifications for performance and longevity.

Let's discuss your coating needs — Contact our experts today to enhance your lab's capabilities!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Tungsten Evaporation Boat for Thin Film Deposition

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications