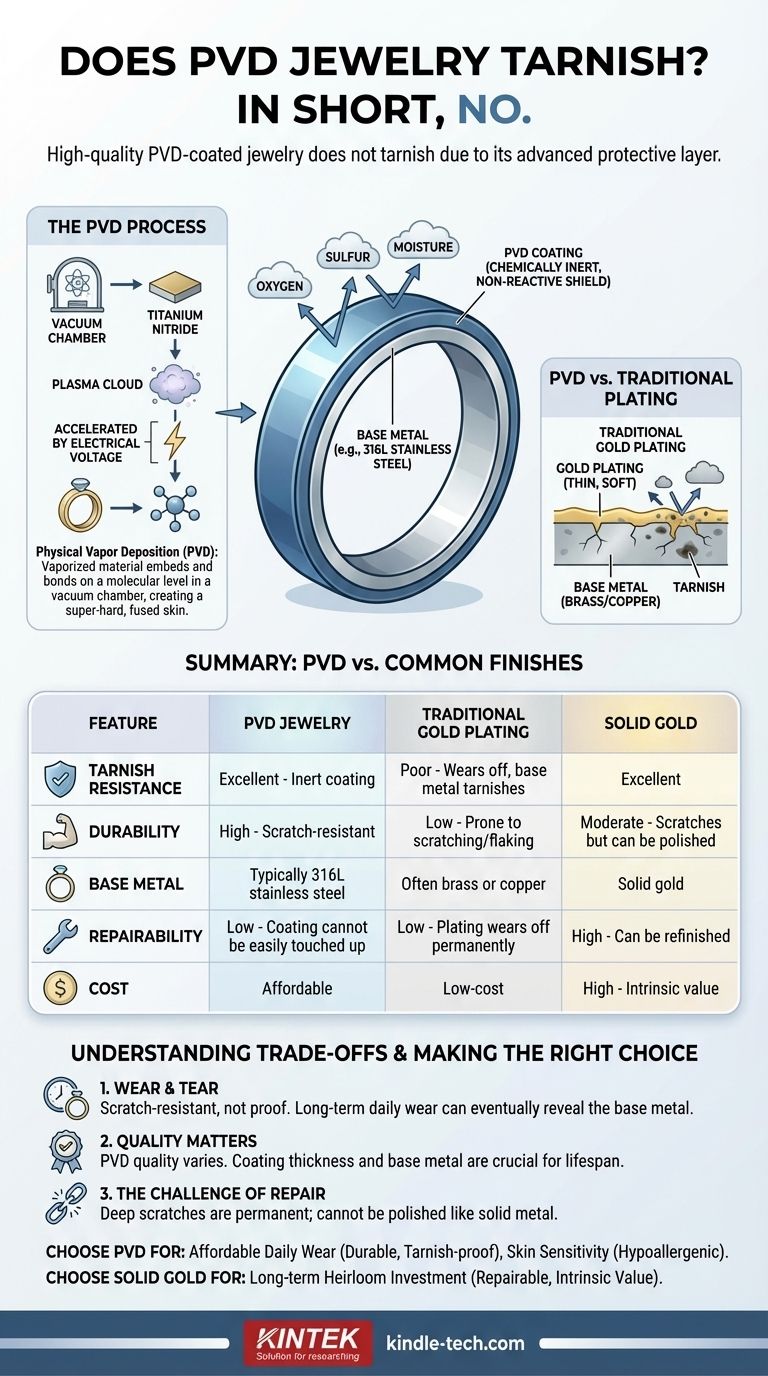

In short, no. High-quality PVD-coated jewelry does not tarnish. The PVD (Physical Vapor Deposition) process creates a protective, inert layer over the base metal, preventing the chemical reaction with air and moisture that causes traditional tarnish on metals like silver or brass.

The core takeaway is that PVD is not a material itself, but an advanced coating process. Its remarkable resistance to tarnish and corrosion comes from this bonded top layer, but the jewelry's ultimate longevity still depends on the quality of both the coating's application and the base metal beneath it.

What Is PVD and Why Doesn't It Tarnish?

To understand its durability, you must first understand the process. PVD is fundamentally different from traditional electroplating.

The Science of Physical Vapor Deposition

Physical Vapor Deposition is a process conducted in a high-tech vacuum chamber. A solid material, often a durable ceramic like titanium nitride, is vaporized into a plasma of atoms. An electrical voltage then accelerates these atoms, causing them to embed and bond on a molecular level with the surface of the jewelry.

Think of it as fusing a new, super-hard skin onto the base metal, rather than simply painting it with a thin layer like traditional plating.

The Protective, Non-Reactive Shield

Tarnish is the result of a chemical reaction, primarily oxidation. Silver reacts with sulfur in the air, and copper or brass react with oxygen.

The materials used for PVD coatings are chosen specifically for being chemically inert. They do not react with oxygen, moisture, or common chemicals. This bonded layer acts as an impenetrable shield, sealing the reactive base metal away from the elements that would cause it to tarnish or corrode.

The Importance of the Base Metal

The most common base metal for high-quality PVD jewelry is 316L surgical-grade stainless steel. This is a crucial detail.

Stainless steel is already highly resistant to rust and corrosion. When you add a PVD coating on top, you get a double layer of protection, making the piece exceptionally durable and hypoallergenic for most people.

PVD vs. Other Common Jewelry Finishes

Understanding how PVD compares to other options clarifies its value proposition.

PVD vs. Traditional Gold Plating

Traditional gold plating involves using an electrical current to deposit a very thin layer of gold onto a base metal (often brass or copper). This layer is soft, measures mere microns thick, and is prone to scratching, flaking, and wearing off quickly with daily use. Once it wears away, the reactive base metal is exposed and will tarnish.

PVD coatings are significantly harder, more durable, and more resistant to abrasion and sweat than any standard plating.

PVD vs. Solid Gold

This is a critical distinction. PVD jewelry is coated, not solid. Its value lies in its durability and affordable appearance.

Solid gold will not tarnish, but it is a relatively soft metal prone to scratching and denting. However, scratches on solid gold can be polished out, and its value is intrinsic to the material itself. A PVD piece cannot be easily repaired if the coating is severely damaged.

Understanding the Trade-offs and Limitations

While PVD is a superior coating technology, it is not invincible. Understanding its limitations is key to managing expectations.

"Wear and Tear" Still Exists

A PVD coating is scratch-resistant, not scratch-proof. Over many years of daily wear, especially on high-contact items like rings, the coating can eventually be worn down or compromised by deep scratches, revealing the base metal underneath.

Quality Varies Dramatically

The term "PVD" is not a guarantee of quality on its own. The thickness of the coating, the quality of the application process, and the choice of base metal all have a massive impact on the final product's lifespan. An extremely cheap PVD piece from an unknown brand will not perform like one from a reputable manufacturer.

The Challenge of Repair

A PVD coating cannot be "touched up" or polished in the traditional sense. If a deep scratch exposes the steel beneath, that spot is permanent. This is the primary trade-off compared to a solid precious metal, which can be refinished throughout its life.

Making the Right Choice for Your Goal

Use this knowledge to select jewelry that aligns with your needs and budget.

- If your primary focus is affordable daily wear: Jewelry with a PVD coating on a stainless steel base is the most durable, tarnish-proof, and practical choice available.

- If your primary focus is a long-term, heirloom investment: Solid gold or platinum remains the standard, as its value is inherent and it can be repaired and refinished indefinitely.

- If your primary focus is avoiding skin sensitivity: Look for PVD coatings on a high-quality, hypoallergenic base metal like surgical-grade stainless steel or titanium.

By understanding the technology, you can confidently choose jewelry that perfectly matches your lifestyle and expectations.

Summary Table:

| Feature | PVD Jewelry | Traditional Gold Plating | Solid Gold |

|---|---|---|---|

| Tarnish Resistance | Excellent (Inert coating) | Poor (Wears off, base metal tarnishes) | Excellent |

| Durability | High (Scratch-resistant) | Low (Prone to scratching/flaking) | Moderate (Scratches but can be polished) |

| Base Metal | Typically 316L stainless steel | Often brass or copper | Solid gold |

| Repairability | Low (Coating cannot be easily touched up) | Low (Plating wears off permanently) | High (Can be refinished) |

| Cost | Affordable | Low-cost | High (Intrinsic value) |

Upgrade your lab's capabilities with KINTEK's precision equipment. Whether you're researching advanced coatings like PVD or developing new materials, our durable lab furnaces, vacuum systems, and consumables ensure accurate, repeatable results. We specialize in serving laboratories that demand reliability for cutting-edge work. Contact our experts today to find the perfect solution for your research needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Platinum Auxiliary Electrode for Laboratory Use

- Custom PTFE Teflon Parts Manufacturer for Magnetic Stirring Bar

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition