In short, no. Silicon carbide is a non-porous ceramic material renowned for its exceptional chemical stability. Due to its dense atomic structure and inert nature, it does not absorb water or suffer degradation from moisture. Its properties make it fundamentally resistant to water in liquid or vapor form.

The core issue isn't just about absorption, but whether moisture compromises silicon carbide's performance. Because SiC is chemically inert and physically dense, it is fundamentally unaffected by water, making it a highly reliable material for applications in humid or aqueous environments.

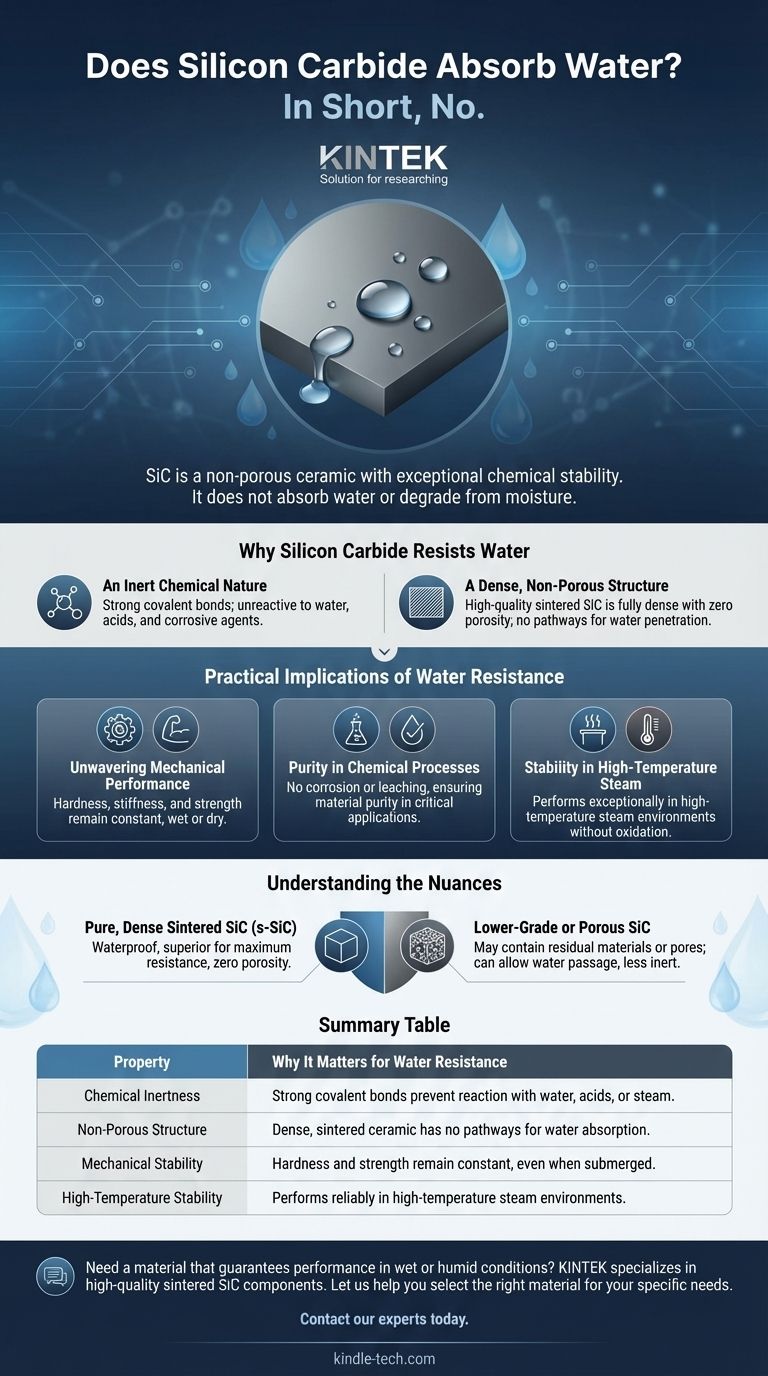

Why Silicon Carbide Resists Water

The resistance of silicon carbide (SiC) to water is not an accidental feature; it is a direct result of its fundamental chemical and physical structure. This makes its performance predictable and reliable.

An Inert Chemical Nature

Silicon carbide is held together by extremely strong covalent bonds. This stable structure makes it highly unreactive.

The material is noted for its resistance to strong acids and other corrosive agents. Given that water is a neutral, far less reactive compound, SiC does not react with it, corrode, or degrade in its presence.

A Dense, Non-Porous Structure

Water absorption in materials typically occurs when there are pores or voids for the liquid to penetrate. High-quality, sintered silicon carbide is manufactured to be fully dense with virtually zero porosity.

Without any pathways into the material's bulk, water molecules cannot be absorbed. The water simply remains on the surface without penetrating the ceramic body.

Practical Implications of Water Resistance

This inherent immunity to water has critical, real-world benefits across various applications.

Unwavering Mechanical Performance

Because SiC does not absorb water, it is not subject to swelling, softening, or internal frost damage that can plague porous materials. Its world-class hardness, stiffness, and strength remain constant whether it is dry or fully submerged.

Purity in Chemical Processes

In industries like semiconductor manufacturing or chemical processing, material purity is paramount. SiC’s inertness means it will not corrode or leach ions into high-purity water or other solutions, preventing contamination.

Stability in High-Temperature Steam

This stability extends beyond liquid water. Silicon carbide performs exceptionally well in environments with high-temperature steam, where more reactive materials would quickly oxidize and fail.

Understanding the Nuances

While pure, dense SiC is waterproof, it's important to understand the distinctions between different grades of the material. Not all "silicon carbide" is identical.

The Role of Binders and Manufacturing

Some forms of SiC, like reaction-bonded silicon carbide, may contain a small amount of residual silicon or other materials from the manufacturing process. While still highly resistant, these secondary phases are technically less inert than pure SiC. For maximum resistance, sintered silicon carbide (s-SiC) is the superior choice.

Porosity in Lower-Grade Materials

Very low-quality or specialized porous SiC (used for filters) is, by design, not dense. In these specific cases, the material will allow water to pass through it, but the SiC ceramic itself does not react with or get damaged by the water.

Surface Wetting vs. Bulk Absorption

It is critical to distinguish between water sitting on a surface and being absorbed by it. Water can wet the surface of SiC, but this is a surface phenomenon that does not affect the material's internal structure or properties.

Making the Right Choice for Your Application

Your specific goal will determine which considerations are most important.

- If your primary focus is general environmental stability: Standard-grade silicon carbide is an excellent choice, as it is fundamentally unaffected by humidity, rain, or immersion.

- If your primary focus is high-purity processing: You must specify high-purity, sintered silicon carbide (s-SiC) to guarantee zero porosity and eliminate any risk of material leaching.

- If your primary focus is structural integrity under load: Any dense form of SiC will maintain its mechanical properties without compromise, as its strength is not affected by moisture.

Ultimately, silicon carbide's inherent chemical stability makes it a definitive choice for applications where water resistance is non-negotiable.

Summary Table:

| Property | Why It Matters for Water Resistance |

|---|---|

| Chemical Inertness | Strong covalent bonds prevent reaction with water, acids, or steam. |

| Non-Porous Structure | Dense, sintered ceramic has no pathways for water absorption. |

| Mechanical Stability | Hardness and strength remain constant, even when submerged. |

| High-Temperature Stability | Performs reliably in high-temperature steam environments. |

Need a material that guarantees performance in wet or humid conditions?

Silicon carbide's inherent resistance to water absorption makes it a superior choice for applications where moisture would compromise other materials. At KINTEK, we specialize in providing high-quality lab equipment and consumables, including sintered silicon carbide components, designed for reliability in the most demanding environments.

Let us help you select the right material for your specific needs. Contact our experts today to discuss how SiC can solve your application challenges.

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Domes for Industrial and Scientific Applications

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- Which is harder silicon carbide or tungsten carbide? Discover the Key to Material Selection

- What are the characteristics of SiC? Unlock High-Temp, Hard, and Chemically Inert Performance

- What is the resistivity of silicon carbide? It's a tunable property from <0.1 ohm-cm to highly resistive.

- What are the properties of SiC? Unlock High-Temperature, High-Frequency Performance

- What is the thermal expansion of SiC? Master Its Low CTE for Superior High-Temp Performance