At its core, an incubator heats itself using a simple electrical resistance heater, but the true technology lies in how that heat is controlled and distributed. These devices don't just produce warmth; they create a highly stable and uniform thermal environment through a sophisticated feedback loop involving a heating element, a temperature sensor, and a digital controller. This system works in unison to maintain a precise temperature setpoint, which is the absolute priority for any application, from cell cultures to neonatal care.

The critical insight is not the heating element itself, but the complete thermal regulation system. An incubator's value comes from its ability to precisely sense, control, and distribute heat to create a stable environment, compensating for any external fluctuations or heat loss.

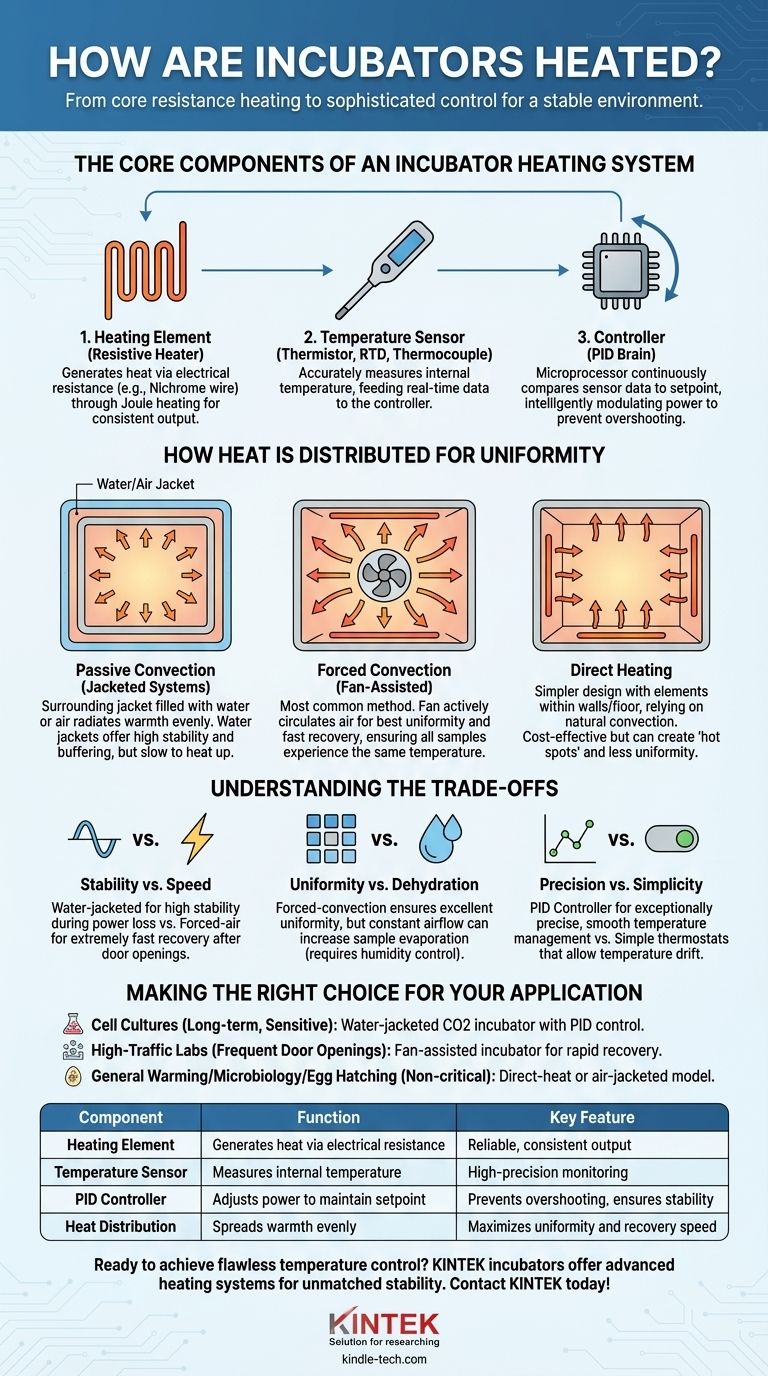

The Core Components of an Incubator Heating System

An incubator's heating system is a closed-loop system, where each component has a distinct role in achieving thermal stability. Understanding these three parts is key to understanding the whole.

The Heating Element

The source of warmth is almost always a resistive heater. This can be a coiled wire (often made of a Nichrome alloy) or a flexible silicone pad bonded to a surface.

When electricity passes through this resistive material, it generates heat—a principle known as Joule heating. These elements are chosen for their reliability and ability to produce consistent heat output.

The Temperature Sensor

To control the heat, the incubator must first accurately measure its internal temperature. This is the job of a high-precision temperature sensor.

Common sensor types include thermistors, RTDs (Resistance Temperature Detectors), or thermocouples. This sensor is placed in a representative location within the chamber to constantly feed real-time temperature data back to the controller.

The Controller (The "Brain")

The controller is a microprocessor that acts as the system's brain. It continuously compares the temperature reported by the sensor to the user's desired setpoint.

Most modern incubators use a PID (Proportional-Integral-Derivative) controller. Unlike a simple thermostat that just turns the heater fully on or off, a PID controller intelligently modulates the power to the heater. It learns the thermal behavior of the incubator to anticipate heat loss and prevent overshooting the target temperature, resulting in exceptionally smooth and stable control.

How Heat is Distributed for Uniformity

Generating heat is only half the battle. Distributing it evenly throughout the chamber is what separates a high-performance incubator from a simple heated box. There are three primary methods.

Passive Convection (Jacketed Systems)

In this design, the main chamber is surrounded by a separate compartment, or "jacket," filled with either water or air. The heating element warms the jacket, which then slowly and evenly radiates heat into the inner chamber from all sides.

Water-jacketed incubators offer superior temperature stability because water holds a large amount of heat. They are excellent at buffering against ambient temperature swings and power outages, but they are heavy and take a long time to heat up.

Forced Convection (Fan-Assisted)

This is the most common method in modern lab incubators. A fan actively circulates air within the chamber, typically drawing it past the heating element and distributing it evenly.

Forced-air systems provide the best temperature uniformity and the fastest recovery time after a door opening. The constant airflow ensures that all samples, whether on the top or bottom shelf, experience the same temperature.

Direct Heating

In simpler or more specialized designs, heating elements are placed directly within the chamber walls or floor. This method relies on natural convection (hot air rising) and radiation to distribute heat.

While cost-effective, direct heating systems are more prone to creating "hot spots" near the element and can have less uniform temperature distribution compared to jacketed or fan-assisted models.

Understanding the Trade-offs

No single design is perfect for every task. Choosing an incubator involves balancing key performance characteristics.

Stability vs. Speed

A water-jacketed incubator is the champion of stability, holding its temperature for hours even during a power loss. However, it is slow to respond to setpoint changes.

A forced-air (fan-assisted) incubator recovers temperature extremely quickly after a door opening but is more susceptible to rapid temperature changes if the power is lost.

Uniformity vs. Dehydration

The fan in a forced-convection system ensures excellent temperature uniformity, which is critical for reproducible results. However, this constant airflow can increase the evaporation of media from cell cultures or moisture from eggs.

This effect is why high-quality CO2 incubators, used for cell culture, also have sophisticated humidity control systems to counteract the drying effect of the fan.

Precision vs. Simplicity

A PID controller provides exceptionally precise temperature management by making small, constant adjustments. This prevents the temperature swings seen with a simple on/off thermostat, which allows the temperature to drift above and below the setpoint. For sensitive biological applications, PID control is non-negotiable.

Making the Right Choice for Your Application

Your specific goal determines which heating technology is most appropriate for your work.

- If your primary focus is ultimate temperature stability for sensitive, long-term cell cultures: A water-jacketed CO2 incubator with PID control is the gold standard.

- If your primary focus is a high-traffic lab with frequent door openings: A fan-assisted (forced convection) incubator will provide the rapid temperature recovery you need to protect your samples.

- If your primary focus is general warming, microbiology, or non-critical applications like egg hatching: A more affordable direct-heat or air-jacketed model is often perfectly sufficient.

Understanding how your incubator creates and manages its environment empowers you to achieve more reliable and repeatable results.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Heating Element | Generates heat via electrical resistance | Reliable, consistent output |

| Temperature Sensor | Measures internal temperature (e.g., thermistor, RTD) | High-precision monitoring |

| PID Controller | Adjusts power to maintain setpoint | Prevents overshooting, ensures stability |

| Heat Distribution | Spreads warmth evenly (e.g., forced convection, water-jacket) | Maximizes uniformity and recovery speed |

Ready to achieve flawless temperature control in your lab? KINTEK's incubators are engineered with advanced heating systems—including PID controllers and forced convection—to deliver unmatched stability and uniformity for your cell cultures, microbiology, and research applications. Let our experts help you select the perfect incubator for your needs. Contact KINTEK today to enhance your lab's performance and reliability!

Visual Guide

Related Products

- Shaking Incubators for Diverse Laboratory Applications

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- What role does a constant temperature orbital shaker play in biomass processing? Maximize Your Fermentation Yields

- What role does a laboratory constant temperature shaker play in the fungal strain cultivation stage? Boost Mycelium Growth

- What is the purpose of a constant temperature incubator shaker? Master Quercetin Adsorption on Nanocomposites

- How does a constant temperature incubator shaker facilitate the enzymatic hydrolysis of lignocellulosic materials?

- What critical reaction conditions does a shaking incubator provide? Optimize Cassava Cellulose Enzymatic Hydrolysis