While the provided reference materials do not contain a specific dollar value for the size of the PVD coating market, they extensively detail the underlying technology and its benefits. This information clearly explains why the market is significant by outlining the process's ability to create highly durable, high-performance coatings that are critical for modern manufacturing and engineering.

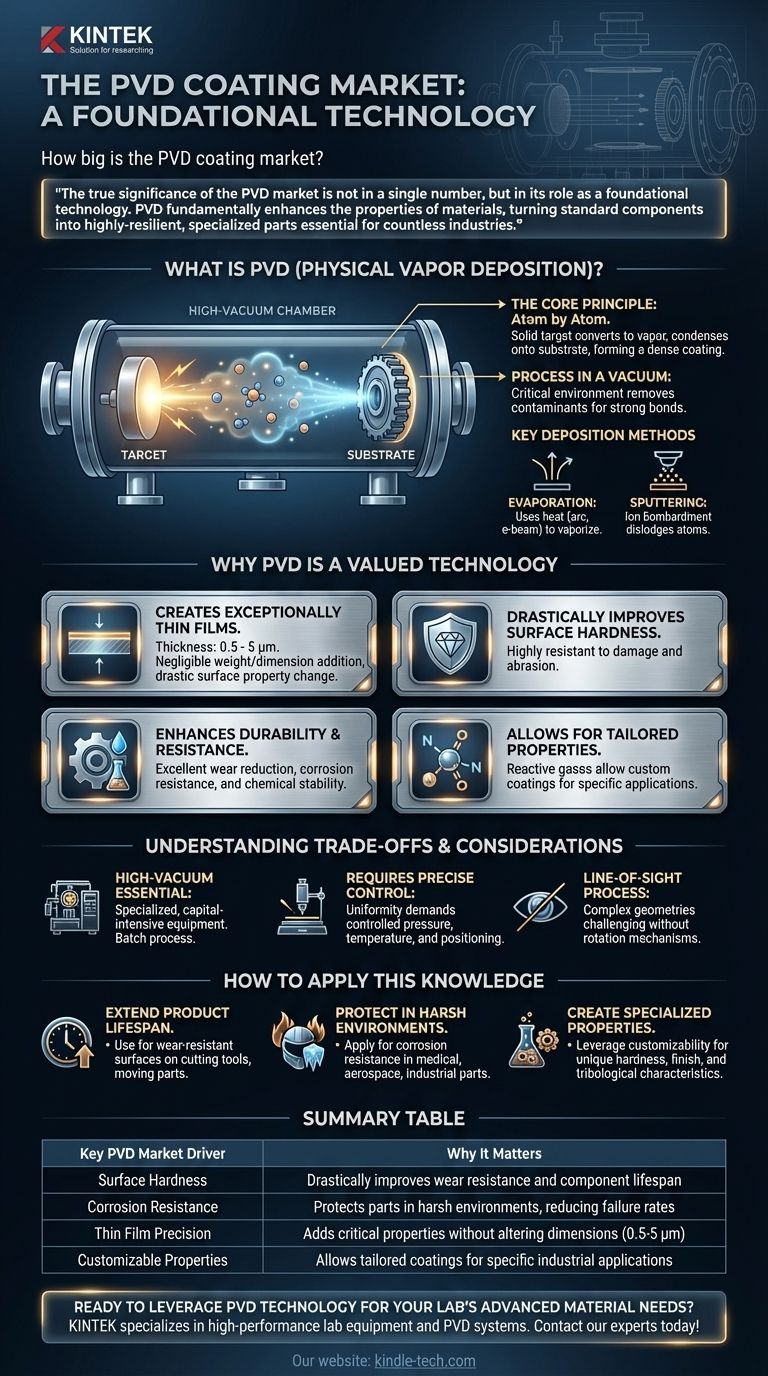

The true significance of the PVD market is not in a single number, but in its role as a foundational technology. PVD fundamentally enhances the properties of materials, turning standard components into highly-resilient, specialized parts essential for countless industries.

What is Physical Vapor Deposition (PVD)?

Physical Vapor Deposition (PVD) is a family of processes used to apply an extremely thin yet durable coating to a surface, known as a substrate. The entire process occurs within a high-vacuum chamber.

The Core Principle: Atom by Atom

At its heart, PVD is a technique for depositing a thin film, one atom or molecule at a time.

A solid source material, called the target, is converted into a vapor. This vapor then travels through the vacuum and condenses onto the substrate, forming a strong, dense, and uniform coating.

The Process in a Vacuum

The component to be coated is placed inside a vacuum chamber. This vacuum is critical, as it removes other particles that could interfere with the coating process.

The target metal is then vaporized. These vaporized atoms travel at very high speed and embed themselves into the surface of the component, creating a very strong bond.

Key Deposition Methods

The most common PVD processes are evaporation and sputtering.

Evaporation uses heat sources, such as a cathodic arc or electron beam, to vaporize the target material. Sputtering involves bombarding the target with energetic ions, which dislodges atoms that then deposit onto the substrate.

Why PVD is a Valued Technology

PVD is not just a cosmetic finish; it provides significant functional improvements to the underlying material, which drives its value and adoption across industries.

Creates Exceptionally Thin Films

PVD coatings are remarkably thin, typically between 0.5 and 5 micrometers (μm). This adds negligible weight or dimension to a component while drastically altering its surface properties.

Drastically Improves Surface Hardness

One of the primary benefits of PVD is a significant improvement in surface hardness. This makes coated parts much more resistant to damage and abrasion.

Enhances Durability and Resistance

PVD coatings provide excellent wear reduction and corrosion resistance. They also improve the chemical stability of the substrate, protecting it from harsh environments.

Allows for Tailored Properties

By introducing reactive gases like nitrogen, oxygen, or acetylene into the vacuum chamber, it's possible to create a wide variety of compound coatings. This allows engineers to tailor the physical and structural properties of the coating for a specific application.

Understanding the Trade-offs and Considerations

While powerful, the PVD process has inherent complexities that represent its primary trade-offs. The value it delivers is a direct result of this controlled, sophisticated environment.

A High-Vacuum Environment is Essential

The entire process must be performed in a vacuum chamber. This requires specialized, capital-intensive equipment and makes it a batch process, not a continuous one.

Requires Precise Control

Achieving a uniform, high-quality coating demands precise control over pressure, temperature, and component positioning. As noted in the references, the part must be carefully positioned and rotated to ensure all necessary areas are coated.

It's a Line-of-Sight Process

The vaporized atoms travel in a straight line from the source to the substrate. This means that complex geometries with deep recesses or hidden surfaces can be challenging to coat uniformly without sophisticated part-rotation mechanisms.

How to Apply This Knowledge

Based on the capabilities described, you can determine where PVD technology fits into your strategic goals.

- If your primary focus is extending product lifespan: Use PVD to create a hard, wear-resistant surface on cutting tools, moving parts, and other components subject to friction.

- If your primary focus is protecting components in harsh environments: Apply PVD coatings for their proven corrosion resistance and chemical stability, ideal for medical, aerospace, and industrial parts.

- If your primary focus is creating specialized material properties: Leverage the customizability of reactive PVD processes to develop unique coatings with tailored hardness, finish, and tribological characteristics.

Ultimately, PVD is a strategic tool for transforming standard materials into high-performance assets.

Summary Table:

| Key PVD Market Driver | Why It Matters |

|---|---|

| Surface Hardness | Drastically improves wear resistance and component lifespan |

| Corrosion Resistance | Protects parts in harsh environments, reducing failure rates |

| Thin Film Precision | Adds critical properties without altering dimensions (0.5-5 μm) |

| Customizable Properties | Allows tailored coatings for specific industrial applications |

Ready to leverage PVD technology for your lab's advanced material needs? KINTEK specializes in high-performance lab equipment and consumables, including PVD systems designed for precision and durability. Whether you're in R&D or production, our solutions help you create wear-resistant, corrosion-proof coatings that elevate your product performance. Contact our experts today to discuss how KINTEK can support your laboratory's coating challenges!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition