To achieve a high deposition rate in PECVD at a low temperature, you must increase the density of reactive chemical species within the plasma without transferring excessive thermal energy to the substrate. This is accomplished by strategically manipulating parameters like RF power and frequency, optimizing precursor gas flow, and, in some cases, utilizing more reactive chemistries. The goal is to make the chemical reaction itself more efficient, bypassing the need for high substrate temperatures.

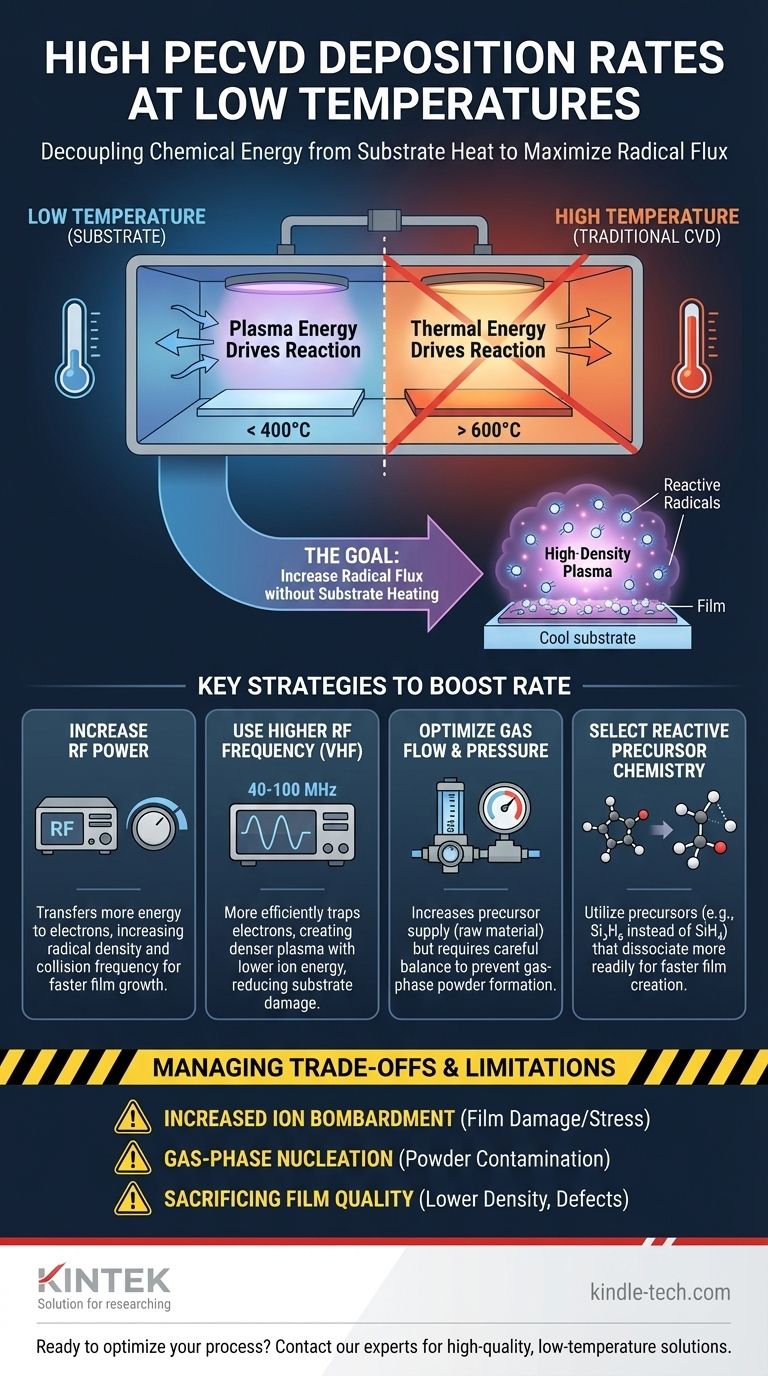

The central challenge is to decouple the energy required for chemical reactions from the thermal energy delivered to the substrate. PECVD's primary advantage is its ability to do this by using plasma to energize precursor gases. The most effective strategies involve creating a very dense, reactive plasma while simultaneously keeping the energy of ions striking the surface low, thereby maximizing deposition rate while minimizing heat and damage.

The Fundamental Principle: Energizing the Gas, Not the Surface

To optimize the process, it's crucial to understand why PECVD works at low temperatures in the first place. This knowledge forms the basis for every adjustment you make.

How Plasma Replaces Heat

In traditional Chemical Vapor Deposition (CVD), high substrate temperatures (often >600°C) provide the thermal energy needed to break down precursor gas molecules and drive surface reactions.

PECVD creates a different environment. An electrical field (usually radio frequency, or RF) energizes free electrons, creating a plasma. These high-energy electrons collide with the precursor gas molecules, breaking them apart into highly reactive fragments called radicals.

These radicals are chemically "primed" to react and form a film on the substrate surface, even at low temperatures (typically <400°C). The energy for the reaction comes from the plasma, not from heating the substrate.

Defining Deposition Rate

The deposition rate is fundamentally determined by the flux of film-forming radicals arriving at the substrate surface. To increase the rate, you must increase this flux.

Key Levers for Increasing Deposition Rate

Several process parameters directly influence the density of reactive radicals in the plasma, allowing you to increase the deposition rate without raising the temperature.

Increasing RF Power

This is the most direct control. Higher RF power transfers more energy to the electrons in the plasma. This results in more frequent and energetic collisions with precursor gas molecules, leading to a higher density of reactive radicals and a faster deposition rate.

The Critical Role of RF Frequency

Standard PECVD systems use a 13.56 MHz frequency. However, moving to Very High Frequency (VHF) sources (e.g., 40-100 MHz) is a powerful technique for high-rate, low-temperature deposition.

Higher frequencies are more efficient at trapping and energizing electrons. This creates a denser, more dissociated plasma at a lower plasma voltage, which means the ions striking the substrate have lower energy. The result is a higher deposition rate with less potential for film damage or substrate heating.

Optimizing Gas Flow and Pressure

Increasing the flow rate of the precursor gas provides more "raw material" for the reaction, which can increase the deposition rate up to a point.

However, pressure must be carefully managed. Too much pressure can lead to undesirable gas-phase reactions where particles form in the plasma itself, not on the substrate. This is a common source of film defects.

Selecting Precursor Chemistry

The choice of precursor gas can have a significant impact. Some molecules dissociate more easily or create more efficient film-forming radicals. For example, when depositing silicon films, disilane (Si₂H₆) is often used to achieve higher deposition rates at low temperatures compared to standard silane (SiH₄) because it breaks down more readily.

Understanding the Trade-offs and Limitations

Pushing for the maximum deposition rate is not without consequences. An expert advisor must help you anticipate and manage the potential downsides.

The Risk of Increased Ion Bombardment

While increasing RF power boosts the deposition rate, it also increases the energy of ions bombarding the substrate. This can be beneficial for creating dense films, but excessive bombardment can introduce compressive stress, create defects, or damage sensitive substrates. This is precisely why higher frequency plasmas are so advantageous—they mitigate this trade-off.

Gas-Phase Nucleation (Powder Formation)

At very high power and pressure, the density of radicals can become so high that they begin to react with each other in the gas phase. This creates dust or powder that can contaminate the chamber and ruin the deposited film. This often defines the upper limit of a stable process window.

Sacrificing Film Quality for Speed

Rapid deposition can sometimes "trap" unwanted elements (like hydrogen in silicon nitride films) or create films with lower density and poorer structural quality. There is often a direct trade-off between the rate of deposition and the final material properties of the film.

Making the Right Choice for Your Goal

The optimal approach depends on the specific constraints of your film and substrate. Your strategy should be tailored to balance the need for speed with the required film quality and substrate integrity.

- If your primary focus is maximizing rate on a robust substrate: Focus first on increasing RF power and precursor flow, as the substrate can tolerate some additional ion energy.

- If your primary focus is depositing high-quality films on a sensitive substrate (e.g., a polymer or organic electronic device): Prioritize using a higher frequency source (VHF or microwave) to create a high-density, low-ion-energy plasma.

- If you are facing film defects or powder formation at high rates: Carefully reduce gas pressure or experiment with plasma pulsing to interrupt gas-phase reactions before they become problematic.

Ultimately, controlling the plasma's energy and density is the key to unlocking fast, high-quality, low-temperature deposition.

Summary Table:

| Strategy | Key Parameter | Effect on Deposition Rate |

|---|---|---|

| Increase Plasma Density | Higher RF Power | Directly increases radical flux and rate |

| Enhance Electron Trapping | Higher RF Frequency (VHF) | Creates denser plasma with lower ion energy |

| Provide More Precursors | Optimized Gas Flow/Pressure | Increases raw material, but risk of powder formation |

| Use Reactive Chemistry | Precursor Selection (e.g., Si₂H₆) | Easier dissociation for faster film growth |

Ready to optimize your PECVD process for high-speed, low-temperature deposition? KINTEK specializes in lab equipment and consumables, providing the expertise and solutions to help you achieve superior film quality on even the most sensitive substrates. Contact our experts today to discuss how we can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What are the technical advantages of using PECVD for nitrogen-doped cobalt catalysts? Enhance OER Reaction Kinetics

- How durable is DLC coating? An Ultra-Hard, Low-Friction Shield for Your Components

- How do pole plate spacing and reaction chamber size affect PECVD? Optimize Your Film Uniformity and Throughput

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- How is diamond-like coating applied? A Guide to PVD vs. PACVD Methods

- What is plasma enhanced chemical vapour deposition PECVD used for? Enable Low-Temp Thin Films for Electronics & Solar

- What is the benefit of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the role of RF-PECVD in VFG preparation? Mastering Vertical Growth and Surface Functionality