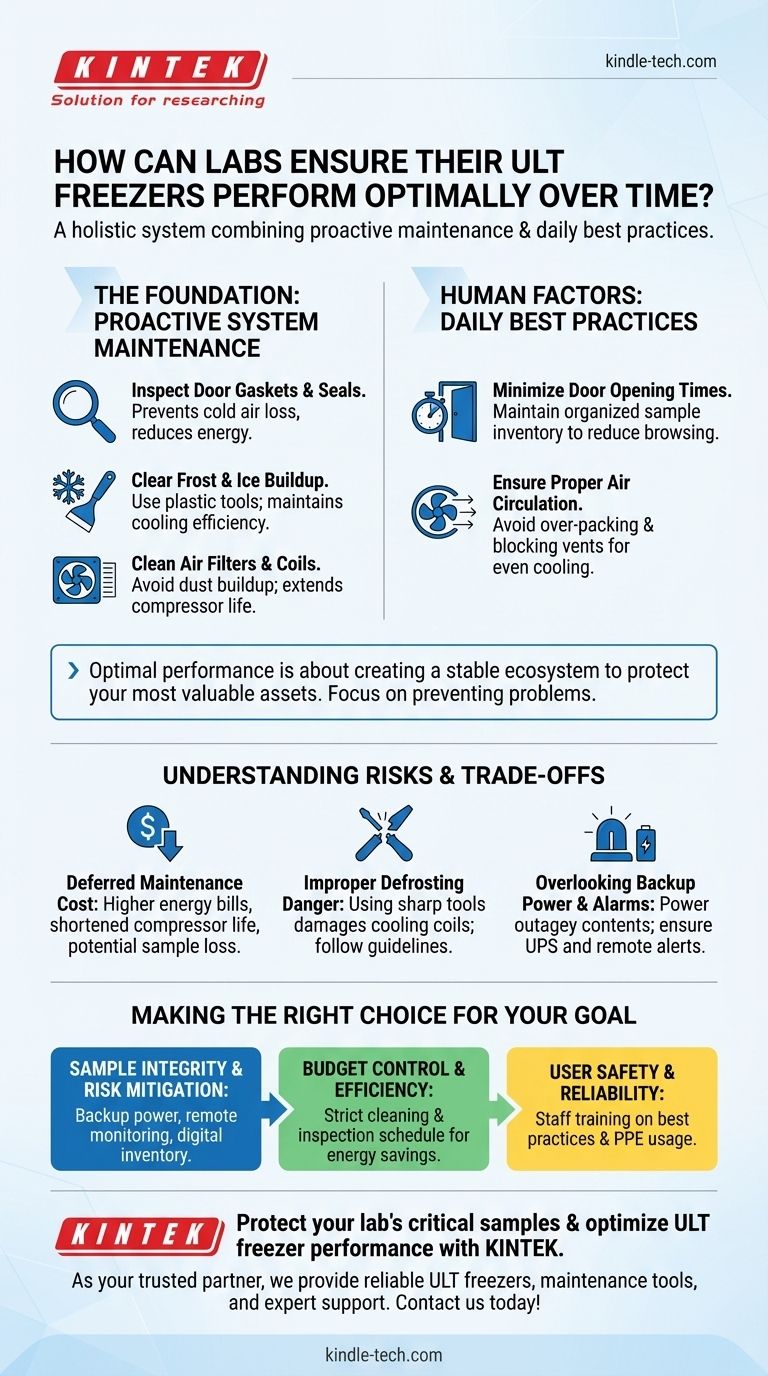

To ensure optimal, long-term performance from a ULT freezer, labs must implement a holistic system that combines proactive physical maintenance with disciplined daily user practices. This approach moves beyond simple repairs and focuses on creating a stable, predictable environment that guarantees the integrity of its contents. Regular inspection of seals, consistent frost removal, and mindful usage are the cornerstones of this system.

Optimal freezer performance is not merely about maintaining the equipment; it is about creating a stable ecosystem to protect your most valuable and often irreplaceable assets. This requires shifting from a reactive mindset of fixing problems to a proactive one of preventing them entirely.

The Foundation: Proactive System Maintenance

A ULT freezer is a high-performance machine operating under extreme stress. Just like any complex equipment, it requires routine checks to prevent cascading failures that compromise its core function.

Inspecting Door Gaskets and Seals

The gasket is the primary barrier between the -80°C interior and the ambient room temperature. The references note that ULT freezers use tight-fitting gaskets to seal inner and outer doors.

Even a minor tear or loss of pliability in a gasket allows warm, moist air to enter the freezer. This forces the compressor to work harder to maintain temperature, increasing energy consumption and frost buildup.

Clearing Frost and Ice Buildup

Frost is an insulator. When it builds up on interior doors, shelves, and around samples, it forces the cooling system to expend more energy to penetrate that insulating layer.

Regularly scraping away excess frost with a plastic or rubber scraper prevents this efficiency loss. A well-sealed freezer (see above) will dramatically slow the rate of new frost formation.

Cleaning Air Filters and Coils

The refrigeration system's condenser coils and air filter are its lungs. They dissipate heat drawn from the freezer cabinet into the surrounding room.

A clogged filter or dusty coils trap heat, forcing the compressor to run longer and hotter. This is a leading cause of premature compressor failure, the most expensive and catastrophic freezer malfunction.

Human Factors: Daily Best Practices

How users interact with the freezer has a direct and significant impact on its performance and lifespan. Simple habits, adopted across the lab, are as critical as any maintenance schedule.

Minimize Door Opening Times

Every time the outer door is opened, the heavy, dense cold air inside spills out, replaced by lighter, warmer, and more humid room air. The double-door system mentioned in the references helps, but disciplined use is still key.

Maintaining an organized sample inventory is the best way to minimize door opening times. Knowing exactly where a sample is located before opening the door reduces "browsing" time and preserves the cold internal environment.

Ensure Proper Air Circulation

ULT freezers require adequate ventilation to expel heat. Placing a unit too close to a wall or another piece of heat-generating equipment can trap this heat, forcing the system to overwork.

Internally, avoid over-packing the freezer. Blocking air vents with boxes prevents cold air from circulating evenly, creating warm spots that can compromise sample integrity and trigger alarms.

Understanding the Trade-offs and Risks

Ignoring maintenance or best practices introduces significant operational risks and financial costs that extend far beyond the initial price of the freezer.

The Cost of Deferred Maintenance

Failing to clean filters or inspect gaskets may seem like a time-saver, but it leads directly to higher electricity bills as the freezer's efficiency drops.

More importantly, it drastically shortens the lifespan of the compressor. The cost of an emergency compressor replacement, coupled with the potential loss of samples during the downtime, far exceeds the cost of routine preventive maintenance.

The Danger of Improper Defrosting

While necessary, defrosting is a high-risk procedure if done improperly. Using sharp metal tools to chip away ice can easily puncture the freezer's interior lining, permanently damaging the cooling coils embedded within the walls.

Always follow the manufacturer's guidelines, use only approved tools (like plastic scrapers), and allocate sufficient time for the process to avoid causing catastrophic damage.

Overlooking Backup Power and Alarms

A freezer can be perfectly maintained, but a simple power outage can destroy its entire contents. A reliable backup power source, such as a generator or uninterruptible power supply (UPS), is non-negotiable for valuable samples.

Furthermore, ensuring the freezer's alarm system is functional and connected to a remote notification service provides the critical early warning needed to respond to a failure before temperatures rise to catastrophic levels.

Making the Right Choice for Your Goal

Your strategy should align with your lab's specific priorities, balancing risk, budget, and operational workflow.

- If your primary focus is sample integrity and risk mitigation: Prioritize investing in a robust backup power system, remote temperature monitoring, and a meticulous digital sample inventory.

- If your primary focus is budget control and operational efficiency: Focus on creating a strict schedule for cleaning air filters and inspecting door gaskets, as these actions provide the highest return on investment for reducing energy costs.

- If your primary focus is user safety and long-term reliability: Emphasize training all lab personnel on best practices, such as minimizing door openings and using proper personal protective equipment (PPE).

A well-maintained ULT freezer is not an expense; it is the physical insurance policy for your most critical scientific assets.

Summary Table:

| Key Maintenance Area | Action Required | Benefit |

|---|---|---|

| Door Gaskets & Seals | Regular inspection for tears/pliability | Prevents cold air loss, reduces energy use |

| Frost & Ice Buildup | Scrape with plastic/rubber tools | Maintains cooling efficiency, prevents insulation |

| Air Filters & Coils | Clean routinely to avoid dust buildup | Extends compressor life, prevents overheating |

| User Practices | Minimize door openings, ensure ventilation | Preserves temperature stability, protects samples |

Protect your lab’s critical samples and optimize ULT freezer performance with KINTEK. As your trusted partner in laboratory equipment and consumables, we provide reliable ULT freezers, maintenance tools, and expert support to ensure your unit operates efficiently for years. Don’t leave sample integrity to chance—contact us today to learn how our solutions can meet your lab’s unique needs!

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

- 608L Essential Laboratory Ultra Low Temperature Freezer For Critical Sample Preservation

People Also Ask

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- What features do ultra-low temperature freezers typically include? Ensuring Absolute Sample Security

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- What is the role of an ultra-low temperature (ULT) freezer in the freeze-thaw synthesis of hydrogel nanocomposites?