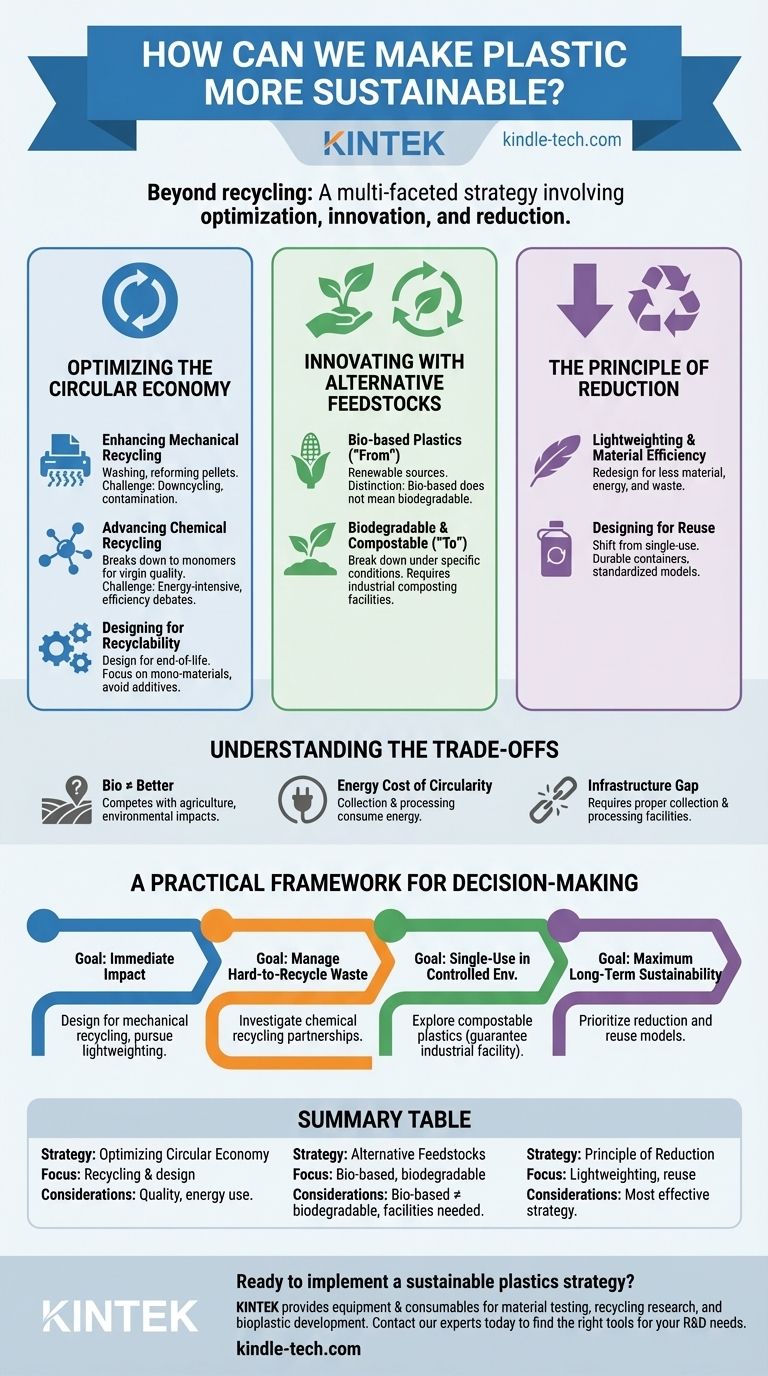

To make plastic more sustainable, we must move beyond a single-minded focus on recycling and embrace a multi-faceted strategy. This involves optimizing the circular economy for existing materials, innovating with alternative feedstocks like bio-based and biodegradable plastics, and, most critically, implementing aggressive reduction and reuse models. The right approach depends entirely on the specific application and its end-of-life context.

The pursuit of sustainable plastic is not about finding a single perfect material. It is about strategically applying a combination of approaches—recycling, bioplastics, and reduction—based on the specific application and its real-world end-of-life pathway.

The Three Pillars of Sustainable Plastics

True progress requires a holistic view that integrates three core strategies. Treating these as isolated solutions often leads to unintended negative consequences. Instead, they should be seen as interconnected tools in a larger system.

Pillar 1: Optimizing the Circular Economy

Before replacing conventional plastics, the first priority is to improve the system for the vast quantities that already exist.

Enhancing Mechanical Recycling Mechanical recycling involves washing, shredding, melting, and reforming plastic into new pellets. This is the most common form of recycling today.

While effective, it often results in downcycling, where the material quality degrades with each cycle, limiting its use in high-performance applications. Contamination is a major challenge.

Advancing Chemical Recycling Chemical recycling, or advanced recycling, breaks plastics down to their original molecular building blocks (monomers). These can then be used to create new plastics of virgin-like quality.

This method can handle mixed or contaminated plastic waste that mechanical recycling cannot. However, it is currently more energy-intensive and less mature, with ongoing debates about its efficiency and environmental footprint.

Designing for Recyclability Sustainability begins at the design phase. Products should be created with their end-of-life in mind.

This means using single materials (mono-materials) whenever possible, avoiding problematic additives or colorants, and using labels and adhesives that can be easily separated during the recycling process.

Pillar 2: Innovating with Alternative Feedstocks

This pillar focuses on changing the fundamental origin and end-of-life properties of plastic.

Bio-based Plastics (The "From" Question) Bio-based plastics are made in whole or in part from renewable biological sources like corn, sugarcane, or cellulose, rather than from petroleum.

A critical distinction is that bio-based does not automatically mean biodegradable. A bio-based PET bottle, for example, is chemically identical to a fossil-fuel-based PET bottle and should be recycled accordingly.

Biodegradable & Compostable Plastics (The "To" Question) These plastics are designed to break down into natural elements under specific environmental conditions.

It is crucial to understand that most require the high heat and moisture of an industrial composting facility. They do not simply disappear in a landfill or the ocean, and they act as a contaminant in traditional recycling streams.

Pillar 3: The Principle of Reduction

The most sustainable plastic is the one that is never created. This principle is the most effective but often the most challenging to implement.

Lightweighting and Material Efficiency This involves redesigning products and packaging to perform the same function with significantly less material. It's a direct way to reduce resource consumption, energy use, and waste generation from the outset.

Designing for Reuse The ultimate goal is to shift from a single-use, disposable mindset to a model built on reuse.

This includes creating durable, refillable containers for consumer products or standardized, reusable shipping crates within a business-to-business supply chain.

Understanding the Trade-offs

There is no "perfect" sustainable plastic. Every choice involves a series of trade-offs that must be carefully evaluated.

"Bio" Does Not Always Equal "Better"

Bio-based plastics compete with agriculture for land, water, and fertilizers, which have their own environmental impacts. Biodegradable plastics can generate methane—a potent greenhouse gas—in landfills if they break down anaerobically, or cause harm to ecosystems if they don't break down as intended.

The Energy Cost of Circularity

Recycling is not an energy-free process. Collection, transportation, sorting, and reprocessing all consume significant energy. While almost always better than producing virgin material, the efficiency of these systems is a critical factor.

The Infrastructure Gap

A perfectly recyclable or compostable product is useless without the infrastructure to process it. Many communities lack access to industrial composting facilities, and recycling capabilities vary dramatically by region. A material choice must align with the available end-of-life infrastructure.

A Practical Framework for Decision-Making

To apply these principles, you must first define your primary goal. Different objectives demand different strategies.

- If your primary focus is immediate impact on existing products: Prioritize designing for mechanical recycling and aggressively pursuing lightweighting opportunities.

- If your primary focus is managing hard-to-recycle waste streams: Investigate chemical recycling partnerships for complex or contaminated plastics that currently go to landfill.

- If your primary focus is single-use items in a controlled environment: Explore compostable plastics, but only if you can guarantee collection and processing in an industrial composting facility.

- If your primary focus is maximum long-term sustainability: Make reduction and reuse models your highest priority, treating material substitution as a secondary option.

True sustainability in plastics comes not from a single solution, but from a deliberate, informed strategy that matches the right approach to the right problem.

Summary Table:

| Strategy | Key Focus | Key Considerations |

|---|---|---|

| Optimizing the Circular Economy | Enhancing mechanical & chemical recycling; designing for recyclability. | Quality degradation in mechanical recycling; energy use in chemical recycling. |

| Innovating with Alternative Feedstocks | Using bio-based materials; developing biodegradable/compostable plastics. | Bio-based ≠ biodegradable; requires specific industrial composting facilities. |

| The Principle of Reduction | Lightweighting, material efficiency, and designing for reuse. | The most effective strategy for long-term sustainability. |

Ready to implement a sustainable plastics strategy in your lab or production process? KINTEK specializes in providing the equipment and consumables needed for advanced material testing, recycling research, and bioplastic development. Whether you're exploring chemical recycling processes or testing the properties of new bio-based polymers, our solutions can help you achieve your sustainability goals. Contact our experts today to find the right tools for your research and development needs.

Visual Guide

Related Products

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Cleaning Racks

- Lab Infrared Press Mold

- No Demolding Lab Infrared Press Mold for Laboratory Applications

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- How should an appropriate PTFE cleaning basket be selected? A Guide to Efficient and Safe Lab Cleaning

- What maintenance procedures are recommended for a PTFE cleaning basket? Extend Equipment Life & Ensure Process Purity

- What is the maximum operating temperature for a PTFE cleaning basket? Avoid Catastrophic Failure at 260°C

- What is the correct way to place items into a PTFE cleaning basket? Master the Art of Perfect, Repeatable Cleaning

- What should be monitored during the cleaning process when using a PTFE cleaning basket? Ensure Reliable Results & Prevent Damage