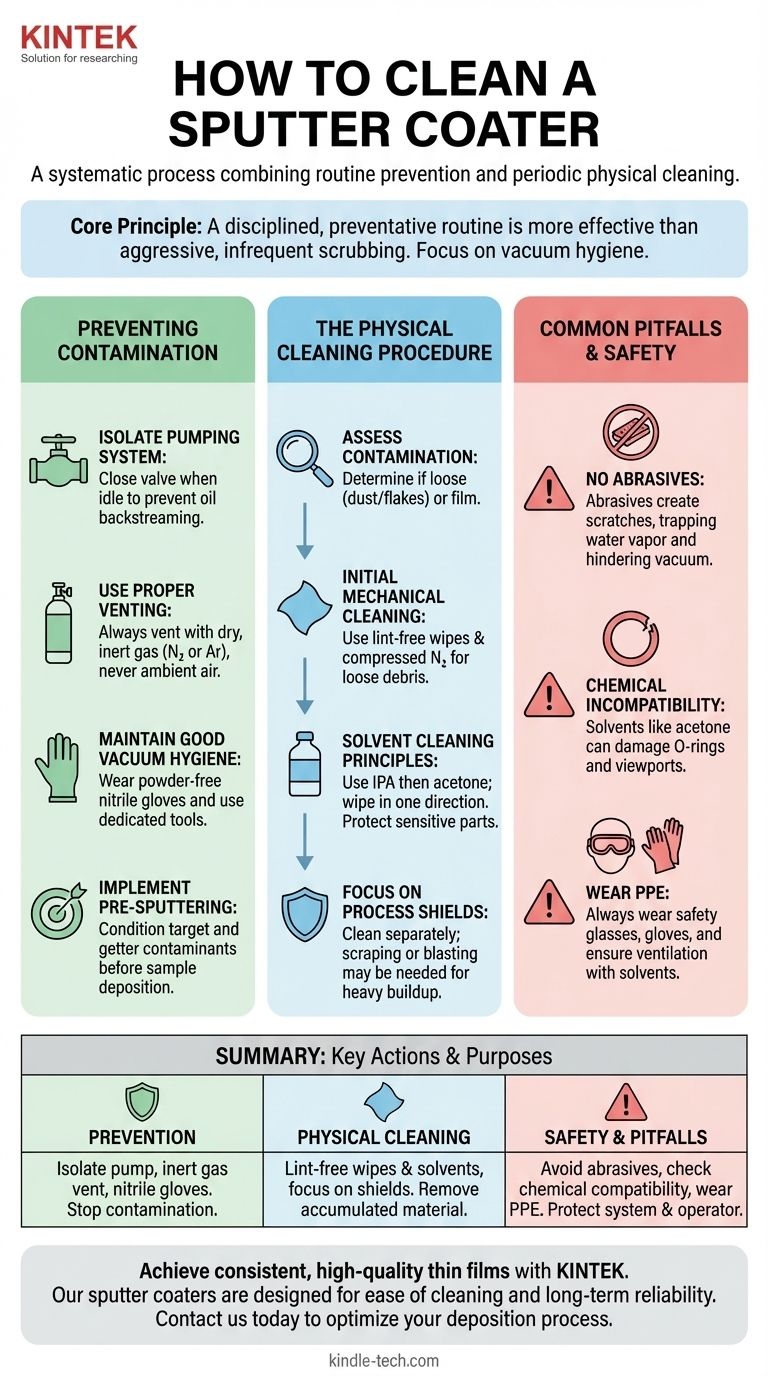

Cleaning a sputter coater is a systematic process that involves two distinct but equally important activities: routine preventative measures to stop contamination before it starts, and periodic physical cleaning of the chamber and its components. The most common source of contamination is hydrocarbon-based pump oil backstreaming into the chamber, which is why isolating the roughing pump when the system is idle is a critical first step in maintaining cleanliness.

The core principle of sputter coater maintenance is not about aggressive, infrequent scrubbing. It is about a disciplined, preventative routine focused on vacuum hygiene, supplemented by targeted, methodical cleaning only when necessary to remove accumulated material.

The Foundation: Preventing Contamination

The most effective way to "clean" a sputter coater is to never let it get dirty in the first place. Contamination is the primary cause of poor film adhesion, hazy coatings, and inconsistent results. A few disciplined habits will solve the majority of problems.

Isolate the Pumping System

As noted, a primary contamination vector is oil from the roughing pump. When the system is not in use but left under vacuum, always close the valve that isolates the roughing pump from the main chamber. This simple action prevents oil vapor from slowly migrating back into the clean environment.

Use Proper Venting Procedures

Never vent the chamber to atmosphere using ambient room air. Room air contains moisture, dust, and aerosols that will immediately contaminate the internal surfaces. Always vent the chamber with a dry, inert gas, such as nitrogen (N₂) or argon (Ar), to maintain a clean and dry interior.

Maintain Good Vacuum Hygiene

Human interaction is a major source of contamination. Always wear powder-free nitrile gloves when handling anything that will go inside the chamber. Oils and particulates from your hands can easily ruin a deposition process. Use clean, dedicated tools that never leave the vacuum area.

Implement Pre-Sputtering (Target Conditioning)

Before depositing onto your actual sample, it is standard practice to sputter onto a shutter for several minutes. This "pre-sputter" process cleans the target surface by removing any oxide layer or contaminants that have settled on it. It also helps to getter (capture) any stray water vapor or other contaminants remaining in the chamber.

The Physical Cleaning Procedure

When preventative measures are not enough or you are restoring an older system, a physical cleaning is required. This must be done methodically.

Assess the Contamination

First, determine the nature of the problem. Are you dealing with loose flakes and dust, or a uniform, hard-to-remove film? The type of contamination dictates the cleaning method.

Initial Mechanical Cleaning

Start with the least aggressive method. Use lint-free wipes (such as Kimwipes) and compressed dry nitrogen to remove any loose dust or flakes from the chamber walls, sample stage, and especially the deposition shields.

Solvent Cleaning Principles

If a film of material or oil remains, you will need to use solvents. Begin with a mild solvent like isopropyl alcohol (IPA) applied to a lint-free wipe. If that is insufficient, you can proceed to a stronger solvent like acetone. Always wipe in one direction to avoid redepositing contaminants.

Focus on the Process Shields

The removable metal shields surrounding the target and chamber are designed to catch the vast majority of sputtered material. These should be removed and cleaned separately. For heavy buildup, mechanical scraping or bead blasting may be necessary, but this should be done with care to avoid damaging the shield surface.

Common Pitfalls and Safety

Mistakes during cleaning can cause more harm than the original contamination. Understanding the trade-offs and risks is essential for any operator.

Abrasives Are a Last Resort

Never use abrasive pads (like Scotch-Brite) or sandpaper on the interior surfaces of the main chamber. These create microscopic scratches that dramatically increase the surface area, trapping more water vapor and making it much harder to achieve a good vacuum in the future.

Chemical Incompatibility

Be aware of the materials in your system. Solvents like acetone can damage or destroy rubber O-rings and acrylic viewports. Always check for compatibility or remove sensitive components before performing a solvent wipe-down.

Personal Protective Equipment (PPE)

When working with solvents, always wear appropriate safety glasses and gloves. Ensure the area is well-ventilated to avoid inhaling fumes. Safety is a non-negotiable aspect of system maintenance.

Making the Right Choice for Your Goal

Your cleaning strategy should be tailored to your operational needs. The goal is not a sterile environment, but a consistently clean one that produces reliable results.

- If your primary focus is routine, high-quality film deposition: Your efforts should be 90% focused on preventative measures like proper venting, pre-sputtering, and glove usage.

- If your primary focus is restoring a heavily contaminated system: Follow a systematic process from least aggressive (dry wipe) to most aggressive (solvent cleaning), ensuring you protect sensitive components.

A disciplined approach to both prevention and cleaning is the key to reliable and repeatable sputter deposition.

Summary Table:

| Cleaning Aspect | Key Action | Purpose |

|---|---|---|

| Prevention | Isolate roughing pump; vent with inert gas; wear nitrile gloves | Stop contamination before it starts |

| Physical Cleaning | Use lint-free wipes & solvents (IPA/acetone); focus on process shields | Remove accumulated material and films |

| Safety & Pitfalls | Avoid abrasives; check chemical compatibility; wear PPE | Protect the system and operator from damage |

Achieve consistent, high-quality thin films with reliable sputter coating equipment from KINTEK.

Proper maintenance is key to performance, and KINTEK specializes in lab equipment and consumables designed for ease of cleaning and long-term reliability. Our sputter coaters are built with vacuum hygiene in mind, helping you prevent contamination and achieve precise results.

Let our experts help you optimize your deposition process. Contact us today to discuss your laboratory's specific needs!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is the pressure in a sputter coater? Master Base vs. Working Pressure for Superior Coatings

- What is the impregnation method of catalyst preparation? Achieve High Dispersion & Activity

- How thick is magnetron sputtering? Achieve Precise Thin-Film Control from Nanometers to Micrometers

- How does a heat treatment work? Master the Process to Engineer Superior Material Properties

- What is direct current pulse magnetron sputtering? Achieve Superior Thin Film Deposition for Insulating Materials

- What are the stages of melting metal? Mastering the 3-Step Process from Solid to Liquid

- How can we reduce plastic waste using technology? Leverage AI, Chemical Recycling & Bioplastics

- What temp is required for brazing? A Guide to Perfect Filler Metal Flow & Strong Joints