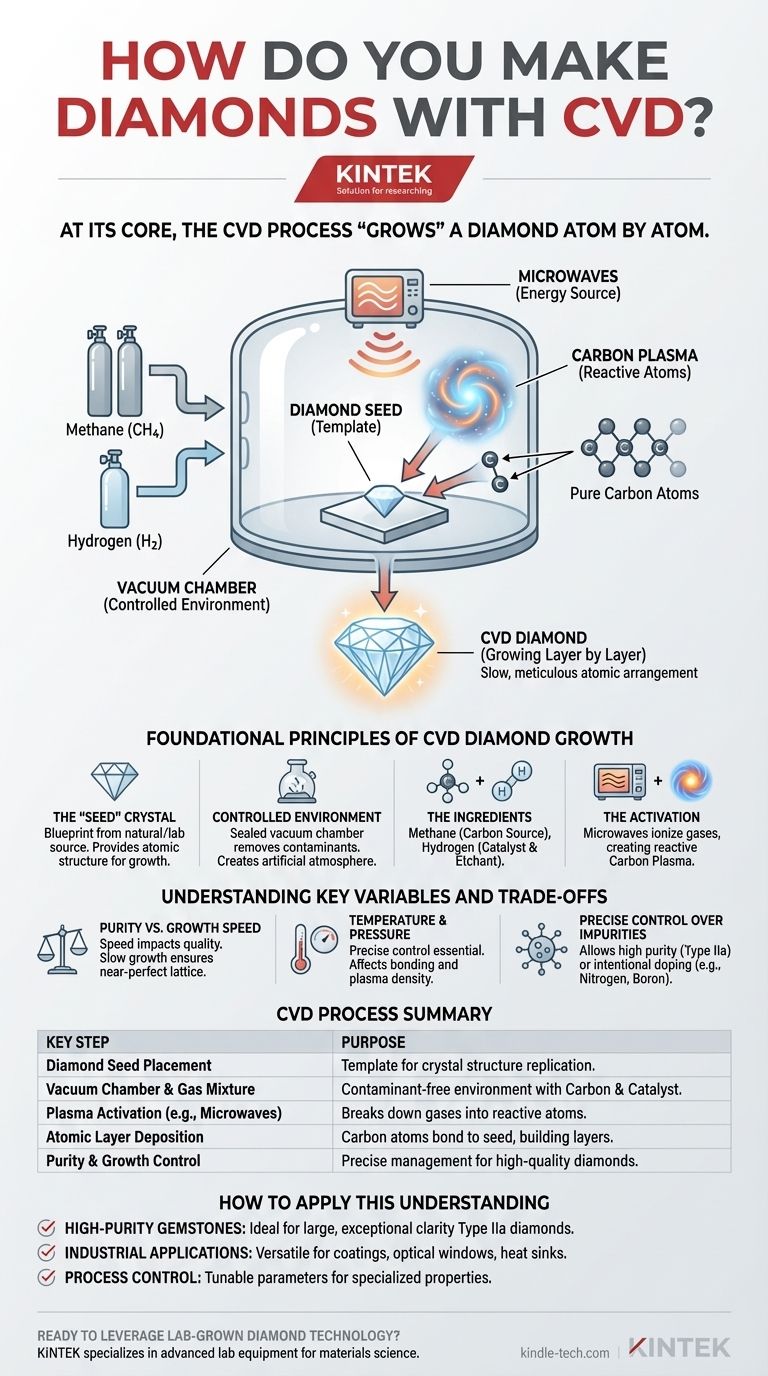

At its core, the CVD process "grows" a diamond atom by atom. This method involves placing a small diamond "seed" into a vacuum chamber, heating it to high temperatures, and introducing a specific mixture of carbon-rich gases. Energy is then used to break down these gases, allowing pure carbon atoms to deposit onto the seed crystal and replicate its perfect lattice structure, slowly building a new, larger diamond.

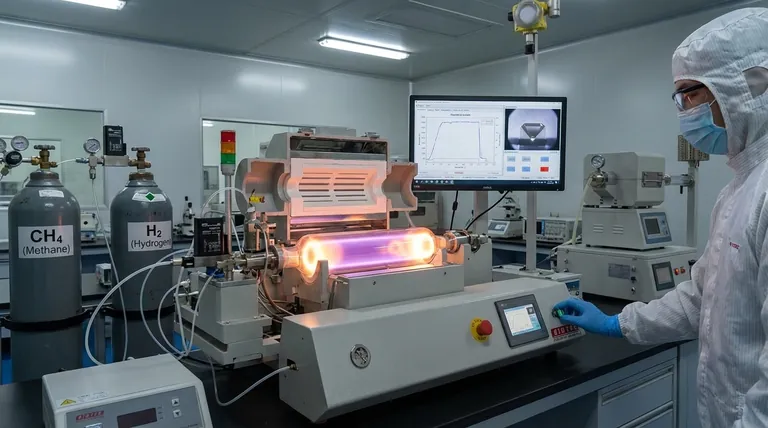

Chemical Vapor Deposition (CVD) is not merely a manufacturing technique; it is a highly controlled chemical engineering process. It succeeds by creating a super-heated, low-pressure environment where simple gases like methane are precisely deconstructed, allowing carbon atoms to settle and bond into the flawless crystalline structure of a diamond.

The Foundational Principles of CVD Diamond Growth

To truly understand how CVD works, you must see it as a sequence of controlled chemical events, each building upon the last to achieve a highly specific outcome: a pure, single-crystal diamond.

The 'Seed' Crystal: A Diamond's Blueprint

The entire process begins with a substrate, typically a very thin slice of a pre-existing diamond. This diamond seed, which can be from either a natural or lab-grown source, acts as the foundational template. Its existing crystal lattice provides the perfect atomic structure for new carbon atoms to bond to, ensuring the new growth continues the diamond's pattern.

The Controlled Environment: The Vacuum Chamber

The growth occurs inside a sealed vacuum chamber. Creating a vacuum is a critical first step, as it removes any atmospheric gases or contaminants that could introduce impurities into the diamond's structure. Once evacuated, the chamber is backfilled with a precise mixture of gases at very low pressures, creating a highly controlled artificial atmosphere.

The Ingredients: Carbon and a Catalyst Gas

The primary gases used are typically methane (CH4) and hydrogen (H2). Methane serves as the source of carbon—the building block of the diamond. Hydrogen plays a crucial dual role: it helps strip carbon atoms from the methane molecules and, just as importantly, it selectively etches away any non-diamond forms of carbon (like graphite) that might try to form on the seed, ensuring the final product is pure diamond.

The Activation: Creating a Carbon Plasma

Heating the chamber to around 800°C is not enough on its own. An energy source, most commonly microwaves, is used to ionize the gases and create a plasma. This super-heated cloud of gas contains fragmented molecules and reactive carbon atoms, which are now chemically active and ready to bond.

The Growth: Atomic Layer by Layer

Within the plasma, the free carbon atoms are drawn to the diamond seed. They bond to its surface, extending the crystal lattice one atom at a time. This process is slow and meticulous, gradually building up layers and causing the diamond to grow in size over a period of weeks. The final result is a rough diamond that is chemically, physically, and optically identical to a mined diamond.

Understanding the Key Variables and Trade-offs

The quality of a CVD diamond is not guaranteed; it is the direct result of managing a delicate balance of competing factors. The process is as much an art as it is a science.

Purity vs. Growth Speed

There is a fundamental trade-off between the speed at which the diamond grows and its final quality. Attempting to accelerate the process by increasing carbon concentration or altering gas flows can lead to inclusions or structural defects in the crystal lattice. The highest-quality diamonds are often grown very slowly to ensure near-perfect atomic arrangement.

The Critical Role of Temperature and Pressure

The temperature and pressure inside the chamber must be maintained with extreme precision. Minor fluctuations can dramatically impact the outcome. The temperature affects how readily carbon atoms bond to the seed, while pressure influences the density and behavior of the plasma. These parameters are constantly monitored and adjusted to maintain the ideal growth environment.

Precise Control Over Impurities

One of CVD's greatest strengths is the ability to control the diamond's chemical purity. By maintaining a clean environment, technicians can produce exceptionally pure diamonds (Type IIa), which are rare in nature. Conversely, they can intentionally introduce specific gases, like nitrogen or boron, during growth to create predictable and consistent fancy-colored yellow or blue diamonds.

How to Apply This Understanding

Understanding the principles of CVD helps clarify why it is chosen for specific goals, from creating large gemstones to developing advanced industrial materials.

- If your primary focus is large, high-purity gemstones: CVD is the ideal method because its slow, layer-by-layer growth in a controlled environment allows for the creation of large, Type IIa diamonds with exceptional clarity.

- If your primary focus is scientific or industrial application: CVD's versatility allows for growing diamond films on various non-diamond substrates, making it perfect for creating ultra-hard coatings, optical windows, or high-performance heat sinks.

- If your primary focus is process control and repeatability: CVD offers more tunable parameters (gas mixture, temperature, power) than other methods, giving producers fine-grained control over the final diamond's properties for specialized applications.

Ultimately, creating a diamond with CVD is a masterful act of turning simple gas into one of the most perfectly ordered and durable materials known to science.

Summary Table:

| Key CVD Diamond Growth Step | Purpose |

|---|---|

| Diamond Seed Placement | Provides a template for carbon atoms to bond to and replicate the crystal structure. |

| Vacuum Chamber & Gas Mixture | Creates a contaminant-free environment with carbon source (methane) and catalyst (hydrogen). |

| Plasma Activation (e.g., Microwaves) | Breaks down gases into reactive carbon atoms ready for deposition. |

| Atomic Layer Deposition | Carbon atoms slowly bond to the seed, building the diamond layer by layer over weeks. |

| Purity & Growth Control | Precise management of temperature, pressure, and gas flow ensures high-quality, defect-free diamonds. |

Ready to leverage lab-grown diamond technology for your research or production? KINTEK specializes in providing advanced lab equipment and consumables tailored to materials science and engineering applications. Whether you're developing CVD processes for gemstones, industrial coatings, or high-performance components, our expertise can help you achieve precise, repeatable results. Contact our specialists today to discuss how our solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What are the applications of metal thin films? Powering Modern Tech from Chips to Solar Cells

- What is the thin film deposition method? A Guide to PVD & CVD Techniques

- How does the Hot Filament Chemical Vapour Deposition (HFCVD) process work? Master High-Quality Diamond Synthesis

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- What is the CVD process of diamond? How Lab-Grown Diamonds Are Created

- What is the mechanism of CVD deposition? A Guide to Surface-Controlled Film Growth

- Is chemical vapor deposition fast? Achieve High-Quality, Uniform Coatings at Industrial Pace

- Waveguide & Slot Antenna Functions in MW-SWP CVD: Achieving High-Density Plasma & Uniform Large-Area Film Deposition