At its core, manufacturing a CVD diamond is a process of controlled crystallization from a gas. A small diamond "seed" is placed in a vacuum chamber, which is then heated and filled with a carbon-rich gas. By energizing this gas into a plasma, individual carbon atoms are freed and settle onto the seed, meticulously building a new, larger diamond layer by layer over several weeks.

While natural diamonds are forged by immense pressure deep within the Earth, the CVD process bypasses this brute force. It instead uses a low-pressure, high-energy plasma environment to break down simple gases and methodically stack carbon atoms onto a substrate, effectively "growing" a diamond with atomic precision.

The Foundational Principle: What is Chemical Vapor Deposition?

Chemical Vapor Deposition (CVD) is a sophisticated manufacturing technique used across many high-tech industries, from semiconductors to optical coatings. Its application to diamond growth is a masterclass in materials science.

From Gas to Solid

The term "deposition" refers to the process where atoms in a gaseous state (a vapor) transition directly into a solid state as they settle onto a surface.

Think of it like frost forming on a cold window. Water vapor in the air doesn't turn to liquid first; it crystallizes directly onto the glass. CVD operates on a similar principle, but with far more control.

The Critical Role of Plasma

Simply introducing carbon gas into a chamber isn't enough. The gas molecules, such as methane (CH4), are stable and won't readily release their carbon atoms.

To solve this, the gas is energized, typically with microwaves, creating plasma. This fourth state of matter is a superheated, ionized gas where electrons are stripped from their atoms. This high-energy environment breaks the chemical bonds in the gas molecules, liberating pure carbon atoms for growth.

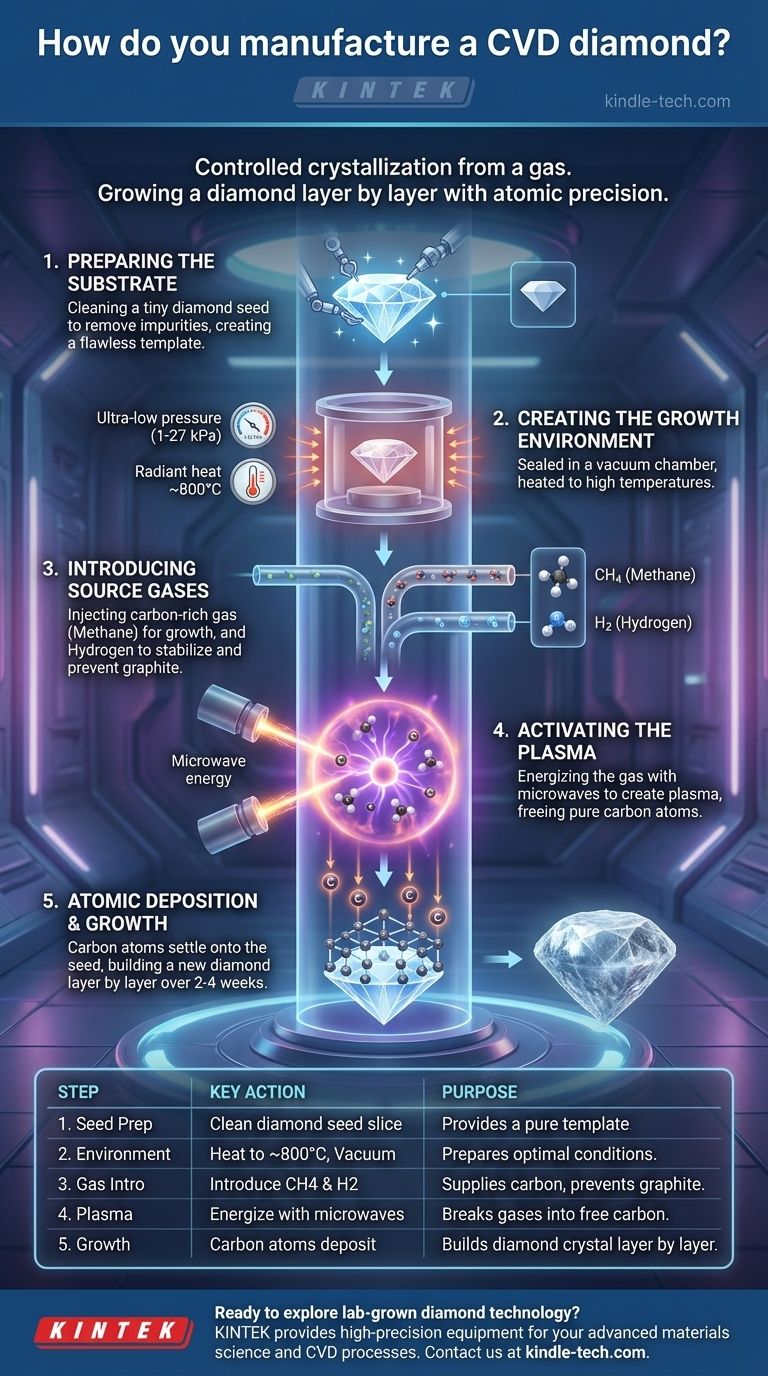

The Step-by-Step Manufacturing Process

Growing a gem-quality diamond requires a precise, multi-stage sequence. Each step is critical to ensuring the final product has the desired purity and crystal structure.

Step 1: Preparing the Substrate

The entire process begins with a diamond seed. This is a very thin, flat slice of a previously created diamond (either natural or lab-grown) that serves as the template for new growth.

The seed is meticulously cleaned to remove any microscopic contaminants. Any impurity on its surface would disrupt the crystalline growth and create a flaw in the final diamond.

Step 2: Creating the Growth Environment

The seed is placed inside a sealed vacuum chamber. The air is pumped out to create an ultra-low-pressure environment, typically between 1 and 27 kPa (a tiny fraction of normal atmospheric pressure).

The chamber is then heated to an extremely high temperature, often around 800°C. This prepares the seed and the environment for the chemical reactions to come.

Step 3: Introducing the Source Gases

A carefully controlled mixture of gases is pumped into the chamber. The primary ingredient is a carbon-rich gas, usually methane, which will provide the atoms for the new diamond.

Hydrogen gas is also introduced in large quantities. It plays a crucial dual role: it helps stabilize the growth surface and actively prevents the formation of graphite (soot), the soft, black form of carbon.

Step 4: Activating the Plasma

Microwave beams or other energy sources are directed into the chamber. This intense energy ionizes the gas mixture, igniting the plasma ball that glows above the diamond seeds.

Inside this plasma, the methane and hydrogen molecules are fractured into a chaotic mix of individual carbon atoms, hydrogen atoms, and other molecular fragments.

Step 5: Atomic Deposition and Growth

From the plasma, carbon atoms precipitate downward and are drawn to the slightly cooler diamond seed. They bond to the seed's crystal lattice, perfectly extending its structure.

This process repeats atom by atom, layer by layer. Over the course of two to four weeks, the seed slowly grows into a larger, rough diamond. A one-carat stone can be created in less than a month.

Understanding the Trade-offs and Limitations

The CVD process is highly technical and requires managing a delicate balance of competing factors to produce a high-quality gem.

Time vs. Quality

While the process is relatively fast compared to geological time, it cannot be rushed. Attempting to grow a diamond too quickly by altering the gas mixture or energy levels can introduce structural defects or inclusions, compromising the final stone's clarity and integrity.

The Battle Against Graphite

Diamond (with its sp3 carbon bonds) is only one form, or allotrope, of carbon. Under many conditions, carbon prefers to form graphite (with sp2 bonds). The precise ratio of hydrogen to methane, the exact temperature, and the pressure are all optimized to favor the formation of the strong diamond bonds and suppress graphite.

Post-Growth Processing

A diamond emerging from a CVD reactor is a rough, unfinished stone. Just like a mined diamond, it must be expertly cut and polished by a skilled lapidary to reveal its brilliance. Some CVD diamonds may also undergo post-growth treatments to enhance their color.

Interpreting the Final Product

Understanding the manufacturing process allows you to appreciate the nature of the final diamond.

- If your primary focus is chemical purity: A CVD diamond is chemically a real diamond. The process often results in Type IIa diamonds, a category defined by its exceptional carbon purity that is found in less than 2% of natural diamonds.

- If your primary focus is structural identity: The process creates a stone with the same crystal lattice, hardness, and thermal conductivity as a mined diamond. It is not a simulant like cubic zirconia; it is structurally and physically diamond.

- If your primary focus is the origin: The definitive difference is the creation story. One is a product of a controlled, human-engineered laboratory environment, while the other is a product of chaotic geological forces over billions of years.

Ultimately, the CVD process is a triumph of materials science, allowing us to engineer one of nature's most extreme materials from the atom up.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Seed Prep | Clean diamond seed slice | Provides a pure template for atomic growth |

| 2. Environment | Heat chamber to ~800°C & create vacuum | Prepares optimal low-pressure, high-temperature conditions |

| 3. Gas Intro | Introduce methane (carbon source) & hydrogen | Supplies carbon atoms; hydrogen prevents graphite formation |

| 4. Plasma | Energize gas with microwaves | Creates plasma to break gas molecules into free carbon atoms |

| 5. Growth | Carbon atoms deposit onto seed | Builds diamond layer by layer over 2-4 weeks |

Ready to explore lab-grown diamond technology for your research or application?

KINTEK specializes in providing high-precision lab equipment and consumables for advanced materials science, including CVD processes. Whether you're growing diamonds for industrial use, research, or gemological applications, our expertise and reliable equipment can help you achieve consistent, high-quality results.

Contact us today to discuss how we can support your laboratory's diamond synthesis or other advanced material needs!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Domes for Industrial and Scientific Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What are the disadvantages of chemical bath deposition? Understanding the Trade-offs for Your Lab

- What are the characteristics of carbon film? A Guide to Cost-Effective Resistors

- What is the CVD coating process? A Guide to High-Performance Thin Film Deposition

- What is the process of thin film deposition? A Guide to PVD, CVD, and Coating Techniques

- What is the synthesis of carbon nanotubes CVD? The Scalable Process for High-Purity Nanotubes

- What is coating in thin film? A Guide to Surface Engineering for Superior Material Performance

- What is chemical vapour deposition of graphene? Grow Large-Area, High-Quality Graphene Films

- What are the primary advantages of the CVD method for growing diamonds? Engineering High-Purity Gems and Components