At its core, a flat die pellet mill works by using pressure and extrusion. Raw material is fed onto a perforated metal disc, called a flat die. A set of rollers then travels across the die's surface, compressing the material and forcing it through the holes to form dense, uniform pellets.

While the mechanics are straightforward, the true challenge lies in understanding the key design variables and operational trade-offs. This knowledge is what separates a successful small-scale production setup from one plagued by inefficiency and high operating costs.

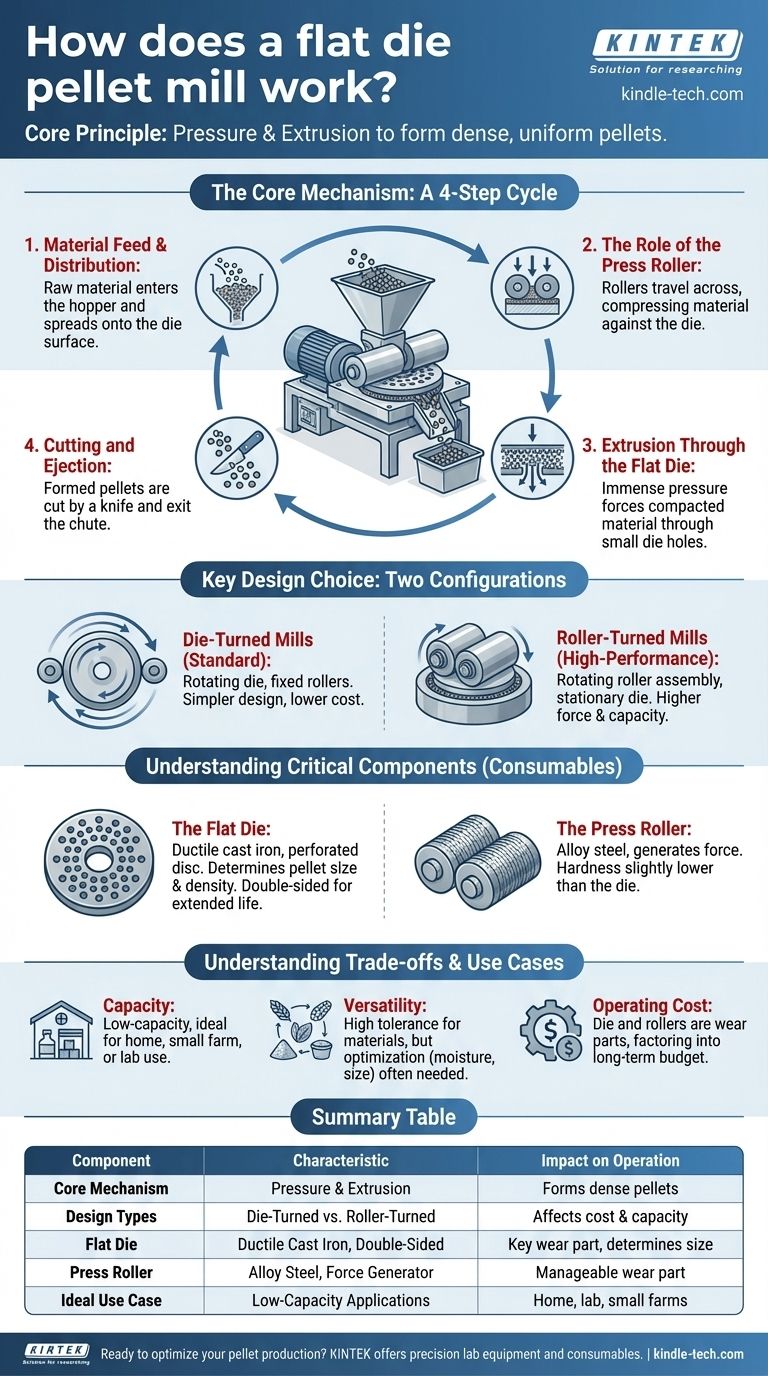

The Core Mechanism: From Raw Material to Pellet

The entire process is a continuous cycle of feeding, compressing, and extruding material. Each stage is critical to the final quality of the pellets.

Step 1: Material Feed and Distribution

Raw material, such as animal feed mash or biomass, is loaded into a feed hopper. From there, it drops into the pelletizing chamber, where it is distributed evenly across the face of the stationary or rotating flat die.

Step 2: The Role of the Press Roller

As the machine operates, the press rollers make contact with the raw material. The immense force generated between the rollers and the die surface compresses the material, creating the necessary pressure for pellet formation.

Step 3: Extrusion Through the Flat Die

This pressure forces the compacted material through the small, cylindrical holes in the flat die. As the material passes through these holes, it is molded into a solid, dense pellet.

Step 4: Cutting and Ejection

As the newly formed pellets are extruded from the other side of the die, they are typically cut to a uniform length by a fixed knife or simply break off due to mechanical stress. They then exit the machine through an outlet chute.

Key Design Choice: Die-Turned vs. Roller-Turned

Not all flat die mills operate identically. The primary design difference lies in which main component rotates, a choice that directly impacts performance, complexity, and cost.

Die-Turned Mills: The Simple Standard

In this design, the flat die rotates while the press rollers remain in a fixed position. Material is carried under the rollers by the spinning die. This is generally a simpler and more common design, often associated with lower cost and easier maintenance.

Roller-Turned Mills: The High-Performance Option

Here, the die remains stationary while the roller assembly rotates. This configuration often involves a more robust gearbox and power transmission system, allowing for higher rotational force and greater production capacity. This increased performance typically comes with a higher initial cost.

Understanding the Critical Components

The quality and lifespan of your pellet mill depend entirely on two core parts: the die and the rollers.

The Flat Die: The Heart of Pellet Formation

The die is a heavy disc, typically made of ductile cast iron, perforated with holes. Its specifications are critical. The hole diameter directly determines the diameter of your pellets. The thickness of the die influences the density and durability of the finished product.

Crucially, the flat die is a wearing part. To mitigate this, many dies are designed to be used on both sides, effectively doubling their operational lifespan before needing replacement.

The Press Roller: The Source of Force

The rollers are made from a superior alloy steel and are responsible for generating the compressive force. Their hardness is engineered to be slightly lower than the die's, ensuring they are a manageable wear component.

A larger roller diameter increases the "grabbing force" on the raw material, allowing the mill to process a thicker layer of feedstock and thus improve overall production capacity.

Understanding the Trade-offs

While simple and effective, flat die mills are not a universal solution. Understanding their limitations is key to using them successfully.

Capacity Limitations

By their very nature, flat die mills are designed for low-capacity applications. Their simple structure and small footprint make them ideal for home use, small farms, or lab-scale testing, but they are not suitable for large, industrial-scale production.

Material Versatility vs. Optimization

Although flat die mills have a high tolerance for a variety of raw materials, achieving optimal results with a specific feedstock may require experimentation. Adjusting moisture content, particle size, and binder additives is often necessary to produce high-quality pellets.

Wear and Tear as an Operating Cost

The press rollers and the flat die are consumables. Their replacement should be factored into your operating budget. The double-sided nature of the die helps reduce this cost, but it remains an unavoidable aspect of long-term operation.

Making the Right Choice for Your Goal

Selecting the right mill configuration depends entirely on your specific production objective.

- If your primary focus is simplicity and low-cost entry for home use: A die-turned model is your most direct and economical solution.

- If your primary focus is maximizing output for a small commercial operation: The higher capacity and efficiency of a roller-turned model may justify its increased cost.

- If your primary focus is versatility across different materials: Choose a model with a robust power source (either a powerful electric motor or a diesel engine) and the ability to easily swap out dies.

By understanding these core principles, you can confidently select and operate a flat die pellet mill that aligns precisely with your production needs.

Summary Table:

| Component/Feature | Key Characteristic | Impact on Operation |

|---|---|---|

| Core Mechanism | Pressure & Extrusion | Forms dense, uniform pellets from raw material |

| Design Types | Die-Turned vs. Roller-Turned | Affects simplicity, cost, and production capacity |

| Flat Die | Ductile cast iron, double-sided | Determines pellet size/density; key wear part |

| Press Roller | Alloy steel, softer than die | Generates compressive force; manageable wear part |

| Ideal Use Case | Low-capacity applications | Best for home use, small farms, or lab testing |

| Key Consideration | Wear parts are consumables | Replacement cost is part of long-term operation |

Ready to optimize your small-scale pellet production? KINTEK specializes in lab equipment and consumables, serving your laboratory needs with precision and reliability. Whether you're setting up a new operation or looking to improve an existing one, our expertise in pellet mill technology can help you achieve efficient, consistent results. Contact us today to discuss your specific requirements and discover the right solution for your project!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

People Also Ask

- What is a punch tablet press? Precision Tableting for R&D and Small Batches

- What is the pressed pellet technique? A Guide to Creating Uniform Solid Samples from Powder

- What are advantages of single punch tablet press machine? Maximize R&D Efficiency with Minimal Material

- What are the advantages of press working operation? Unlock High-Speed, Low-Cost Mass Production

- What are the different parts of a single punch tablet machine? The Core Components Explained