At its core, a heating element fails when the special wire inside it breaks. This break, which stops the flow of electricity and heat production, is almost always the result of a gradual process of degradation caused by factors like high heat, electrical stress, or physical damage.

The failure of a heating element is rarely a sudden event. It's the final outcome of a slow breakdown, where the resistive material is progressively weakened by oxidation, power fluctuations, and repeated thermal cycles until it can no longer withstand the electrical current.

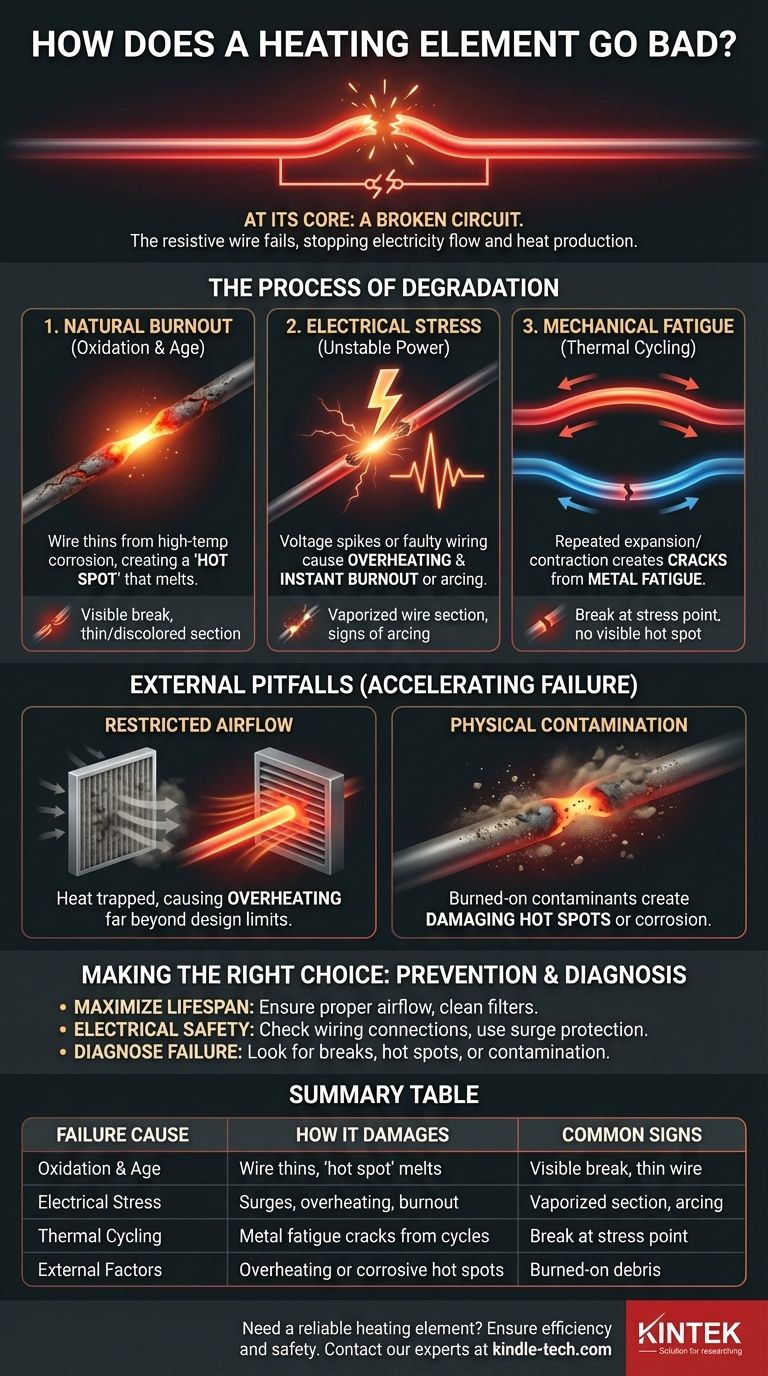

The Core Failure Mechanism: A Broken Circuit

To understand failure, we must first understand the function. A heating element is a simple but effective device designed to operate under extreme conditions.

How a Heating Element Works

A heating element is essentially a controlled resistor. When a high electrical current is forced through its resistive wire (often made of a nickel-chromium alloy called nichrome), the resistance converts that electrical energy directly into heat.

This process is incredibly demanding. The element glows red hot, reaching extreme temperatures by design, and is expected to do so repeatedly for years.

The Point of Failure

Every failure ultimately comes down to a single point: the resistive wire can no longer form a complete electrical circuit. This physical break means electricity stops flowing, and no more heat can be generated. The reasons for that break are what truly define the element's failure.

Primary Causes of Element Degradation

Several forces are constantly working to weaken the resistive wire. Over time, one or more of these will lead to a break in the circuit.

Natural Burnout: Oxidation and Age

The most common failure mode is simple burnout from old age, driven by oxidation. When the element heats up, the metal reacts with oxygen in the air. This process slowly corrodes the wire, making it thinner and more brittle.

As a section of the wire thins, its electrical resistance at that specific spot increases. This creates a "hot spot" that gets even hotter than the rest of the element, accelerating the oxidation process there. Eventually, this spot becomes so thin and hot that it simply melts or vaporizes, breaking the circuit.

Electrical Stress: The Impact of Unstable Power

The electrical supply itself can be a source of failure. This isn't about "inadequate power," but rather about instability.

A voltage spike or power surge can send a massive, instantaneous current through the element, far exceeding its design limits. This can vaporize a weak point in the wire instantly. Similarly, faulty or loose wiring can cause arcing and intermittent power, which creates repeated, intense thermal shocks that fatigue the metal.

Mechanical Fatigue: The Toll of Heating and Cooling

Every time the element turns on, it gets extremely hot and expands. When it turns off, it cools and contracts. This endless cycle of expansion and contraction is known as thermal cycling.

Over thousands of cycles, this repeated mechanical stress can create microscopic cracks in the resistive wire. Over time, these cracks grow until the wire breaks from simple metal fatigue.

Common Pitfalls: External Factors That Accelerate Failure

While every element will eventually fail, certain external conditions can drastically shorten its operational lifespan. These are often related to system maintenance.

The Danger of Restricted Airflow

In forced-air systems like a furnace or clothes dryer, a steady flow of air is required to carry heat away from the element. If a filter becomes clogged or a vent is blocked, air cannot flow freely.

The heat generated by the element has nowhere to go, causing the element to overheat far beyond its designed operating temperature. This extreme heat rapidly accelerates oxidation and leads to a much faster burnout.

The Effect of Physical Contamination

Dust, lint, moisture, or other debris can settle on a heating element. When the element heats up, this contamination can burn onto the surface.

This can either trap heat against the wire, creating a damaging hot spot, or cause a chemical reaction that corrodes the material. In either case, the contamination creates a point of weakness that becomes the eventual point of failure.

Making the Right Choice for Your Goal

Understanding why an element fails empowers you to diagnose issues and extend the life of your equipment through proper maintenance.

- If your primary focus is maximizing lifespan: Ensure proper airflow by regularly cleaning or replacing filters and keeping vents clear.

- If your primary focus is electrical safety: Periodically check for secure wiring connections to the appliance and consider surge protection for high-value equipment.

- If you are diagnosing a failed element: Look for visible signs of a break, thin or discolored hot spots, or signs of external contamination to understand the root cause of the failure.

By recognizing that failure is a process, not an event, you can take simple steps to ensure your systems operate safely and reliably for years to come.

Summary Table:

| Failure Cause | How It Damages the Element | Common Signs |

|---|---|---|

| Oxidation & Age | Wire thins and weakens from high-temperature corrosion, creating a 'hot spot' that melts. | Visible break, thin/discolored wire section. |

| Electrical Stress | Power surges or faulty wiring cause overheating and instant burnout or metal fatigue. | Vaporized wire section, signs of arcing. |

| Thermal Cycling | Repeated expansion and contraction from on/off cycles creates cracks from metal fatigue. | Break at a stress point, no visible hot spot. |

| External Factors | Blocked airflow causes overheating; contamination creates corrosive hot spots. | Burned-on debris, element overheating the appliance. |

Need a reliable heating element for your lab equipment? The right element is critical for consistent results and safety. KINTEK specializes in high-performance lab equipment and consumables, offering durable, precision-engineered heating elements designed for longevity. Ensure your lab's efficiency and safety — contact our experts today for a consultation!

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- What is the material used in high temperature furnace element? Choose the Right Element for Your Application

- How are heating elements made? The Science of Self-Regulating PTC Ceramic Heaters

- What are the high temperature furnace elements to be used in oxidizing environments? Select the Right Element for Your Lab

- Can a heating element overheat? The Critical Causes and Safety Risks Explained

- What is the advantage of a quartz heater? Get Instant, Targeted Warmth for Maximum Efficiency

- How does the placement of K-type or R-type thermocouples affect temperature control? Ensure Precise Pyrolysis Results

- What is the purpose of using a Pt-Rh thermocouple in magnesium experiments? Ensure Precise Vapor Collection

- Which metal works best as a heating element? Choose the Right Alloy for Your Temperature & Environment