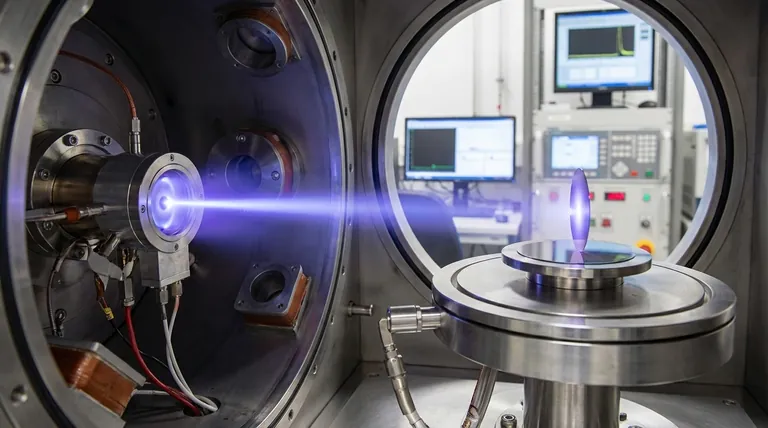

At its core, an ion beam is a highly controlled stream of charged atoms or molecules. These particles, called ions, are generated, accelerated to high energy by electric fields, and then directed as a focused beam toward a target. This technology allows us to manipulate materials with atomic-level precision, essentially acting as a subatomic chisel or paintbrush.

The true significance of an ion beam is not just its power, but its precision. By independently controlling the energy and direction of individual ions, we gain the ability to precisely remove, add, or alter materials in ways that are impossible with conventional methods.

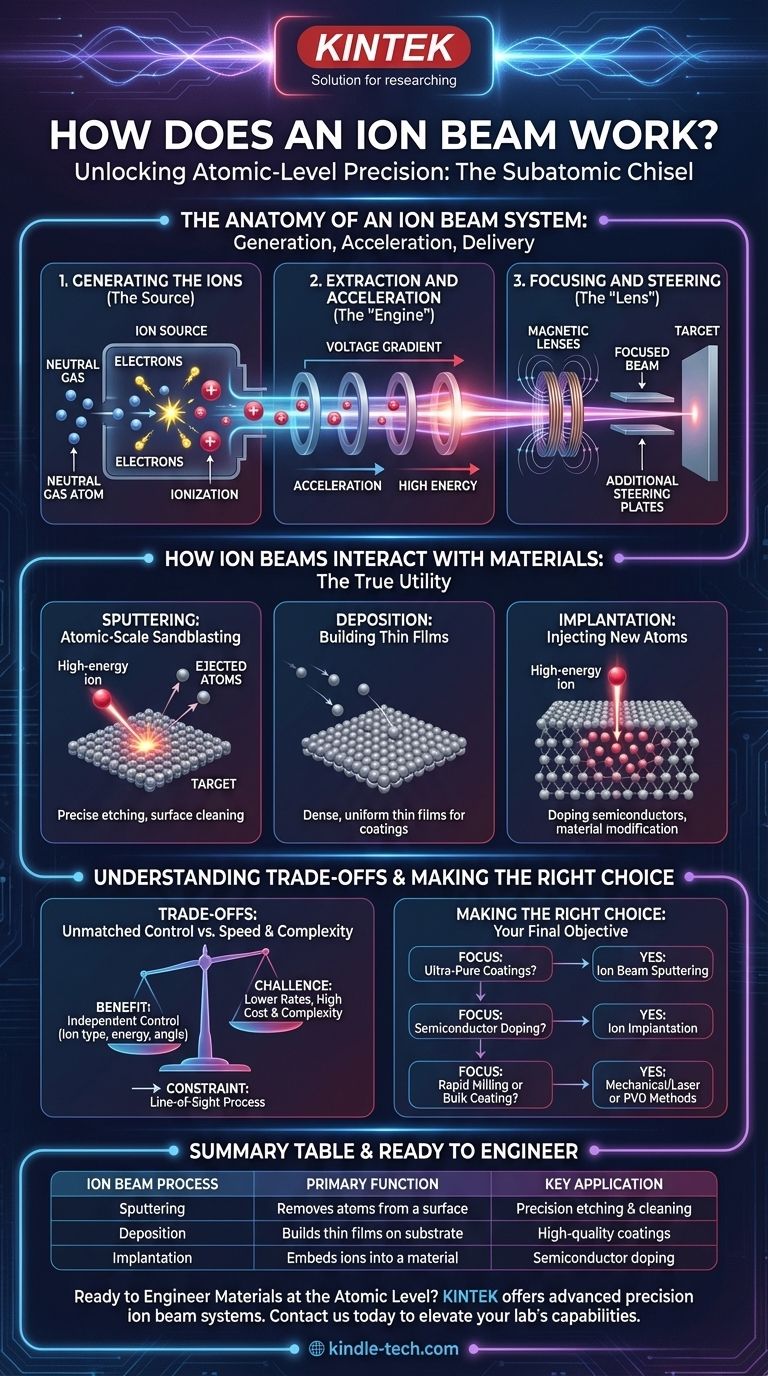

The Anatomy of an Ion Beam System

To understand how an ion beam works, it's best to break the system down into its three fundamental stages: generation, acceleration, and delivery.

Step 1: Generating the Ions (The Source)

It all begins by creating the ions. This typically happens inside an ion source, where a neutral gas, like argon, is introduced.

Energy is then added to this gas—often by bombarding it with electrons—which knocks other electrons off the neutral gas atoms. This process, called ionization, leaves the atoms with a net positive charge, turning them into ions.

Step 2: Extraction and Acceleration (The "Engine")

Once created, the positively charged ions are pulled out of the source using a strong electric field, a process called extraction.

They are then accelerated through a series of electrodes with carefully controlled voltages. Think of it like a ball rolling down an increasingly steep series of hills; the electric fields provide the "gravity" that accelerates the ions to a specific, high-energy state. The final energy is a critical, tunable parameter.

Step 3: Focusing and Steering (The "Lens")

After acceleration, the stream of ions forms the "beam." This beam is often too wide for precise work.

Magnetic or electrostatic lenses are used to focus the beam down to a very fine point, much like an optical lens focuses light. Additional fields can then be used to steer or scan this focused beam across the surface of a target with incredible accuracy.

How Ion Beams Interact with Materials

The true utility of an ion beam becomes clear when it hits a target. The high energy of the ions enables several distinct interactions.

Sputtering: Atomic-Scale Sandblasting

When a high-energy ion strikes a solid target, it transfers its momentum to the atoms on the surface. This collision can eject target atoms, a process known as sputtering.

This is a highly controlled method of erosion. It can be used to precisely etch patterns into a material or to clean a surface with atomic-level purity before another process.

Deposition: Building Thin Films

The atoms ejected during sputtering don't just disappear. They can be directed to land on a nearby object, called a substrate.

This process, ion beam deposition, builds up an exceptionally high-quality thin film on the substrate. Because the sputtered atoms have high kinetic energy, they form films that are denser and more uniform than those made by other methods.

Implantation: Injecting New Atoms

In some cases, the goal is not to remove atoms from the target but to embed the beam's ions directly into it. This is ion implantation.

By controlling the beam's energy, we can precisely control the depth at which the ions come to rest inside the target material. This is the foundational technology used to "dope" semiconductors, changing their electrical properties to create the transistors that power all modern electronics.

Understanding the Trade-offs

While powerful, ion beam technology is not a universal solution. Its precision comes with specific trade-offs.

The Benefit: Unmatched Control

The primary advantage of an ion beam is the independent control over all beam parameters: ion type, energy, current, and angle. This allows for the engineering of material properties and the creation of films with superior density, purity, and adhesion.

The Challenge: Speed and Complexity

Ion beam systems are highly complex and expensive. Deposition and etching rates are typically much lower than for less-controlled techniques like magnetron sputtering. This makes ion beams best suited for high-value applications where quality is more important than throughput.

The Constraint: Line-of-Sight Process

An ion beam travels in a straight line. This means the process is "line-of-sight," making it difficult to uniformly coat or etch complex, three-dimensional shapes without sophisticated part manipulation.

Making the Right Choice for Your Goal

Deciding whether to use an ion beam depends entirely on your final objective and the level of precision required.

- If your primary focus is creating ultra-pure, dense optical coatings: Ion beam sputtering is an ideal choice due to the high quality of the resulting film.

- If your primary focus is modifying the electrical properties of a semiconductor: Ion implantation is the industry-standard method for precise and repeatable doping.

- If your primary focus is rapidly milling a large feature or pattern: A mechanical or laser-based method would likely be far more efficient.

- If your primary focus is high-speed, bulk coating of simple parts: A less complex PVD method like thermal evaporation or magnetron sputtering may be more cost-effective.

Understanding an ion beam moves you from thinking about materials to actively engineering them at the atomic level.

Summary Table:

| Ion Beam Process | Primary Function | Key Application |

|---|---|---|

| Sputtering | Removes atoms from a surface | Precision etching and surface cleaning |

| Deposition | Builds thin films on a substrate | High-quality optical and electronic coatings |

| Implantation | Embeds ions into a material | Semiconductor doping and material modification |

Ready to Engineer Materials at the Atomic Level?

At KINTEK, we specialize in providing advanced laboratory equipment, including precision ion beam systems, to help you achieve unparalleled control in material science. Whether you're developing next-generation semiconductors, creating high-performance optical coatings, or conducting cutting-edge research, our solutions deliver the accuracy and reliability your work demands.

Contact us today to discuss how our ion beam technology can elevate your lab's capabilities and drive your innovations forward. Get in touch now!

Visual Guide

Related Products

- Anion Exchange Membrane for Laboratory Use

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

People Also Ask

- What are the units for deposition rate? Mastering Thickness and Mass Metrics for Your Process

- What are the benefits of diamond-like carbon coating? Boost Component Life with Extreme Hardness & Low Friction

- What is CVD processing? Build High-Performance Thin Films with Chemical Vapor Deposition

- What are the advantages and applications of Low Pressure Chemical Vapour Deposition (LPCVD)? Expert Guide

- What is DC reactive sputtering technique? A Guide to Creating High-Quality Compound Thin Films

- How do Mass Flow Controllers (MFCs) influence LDIP properties during CVD? Achieve Precise Isotropic Carbon Synthesis

- What is the purpose of CVD? Grow High-Performance Thin Films with Atomic Precision

- What is CVD in MEMS? The Foundational Process for Building Micro-Scale Devices