At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a process for creating thin, high-quality films on a substrate. It uses the energy from a plasma, rather than high heat, to drive the chemical reactions that form the coating. This allows for deposition at significantly lower temperatures, making it a highly versatile technique.

The essential difference between PECVD and traditional methods is its energy source. Instead of relying solely on thermal energy (high heat), PECVD uses an energized plasma to break down precursor gases and deposit a superior film on even temperature-sensitive substrates.

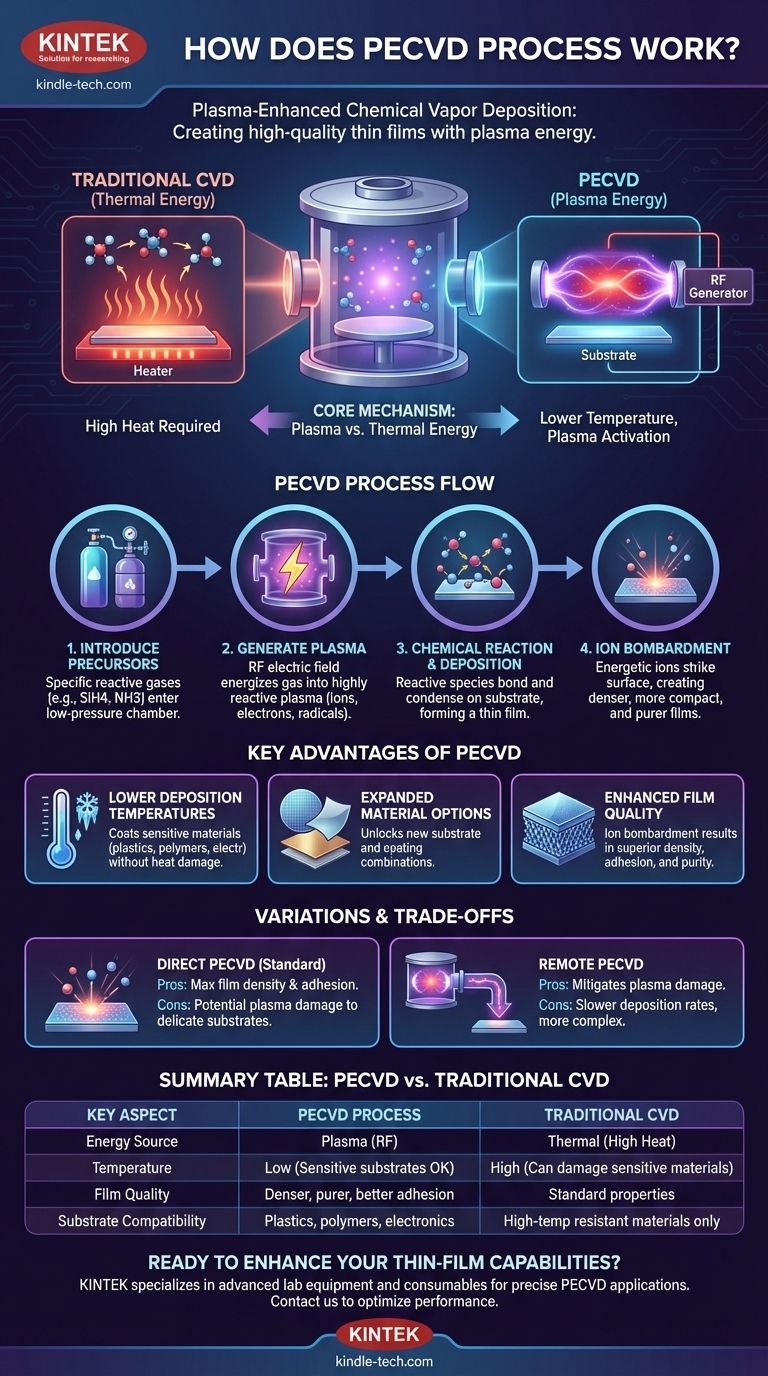

The Core Mechanism: Plasma vs. Thermal Energy

Traditional Chemical Vapor Deposition (CVD) requires heating a substrate to very high temperatures to provide the energy needed to break down gases and form a film. PECVD accomplishes this same goal using a different, more efficient energy source.

Introducing the Precursor Gases

The process begins by introducing specific reactive gases, known as precursors, into a low-pressure vacuum chamber containing the substrate. For example, to create a silicon nitride film, silane (SiH4) and ammonia (NH3) gases might be used.

Generating the Plasma

An electric field, typically Radio Frequency (RF), is applied across the gas in the chamber. This powerful field energizes the gas, stripping electrons from the atoms and creating a plasma—a highly reactive state of matter consisting of ions, electrons, and neutral radicals.

The Chemical Reaction and Deposition

These highly reactive species within the plasma readily break apart and react with each other. They then condense on the cooler surface of the substrate, building up a thin, uniform film layer by layer. The plasma provides the activation energy for this reaction, a role normally filled by intense heat.

The Role of Ion Bombardment

A key secondary benefit of the plasma is ion bombardment. The energetic ions in the plasma strike the substrate's surface during deposition. This action helps to create denser, more compact, and purer films than might be achieved otherwise.

Key Advantages of the PECVD Process

Using plasma as the primary energy driver gives the PECVD process several significant advantages over purely thermal methods.

Lower Deposition Temperatures

This is the most critical advantage. Since plasma energy drives the reaction, substrates do not need to be heated to extreme temperatures. This allows for the coating of materials like plastics, polymers, and other sensitive electronic components that would be damaged or destroyed by traditional CVD.

Expanded Material and Substrate Options

The ability to operate at low temperatures vastly expands the range of possible substrates and coatings. It unlocks material combinations that are otherwise impossible to achieve with high-temperature processes.

Enhanced Film Quality

The ion bombardment inherent in the process enhances the physical properties of the deposited film. This often results in coatings with superior density, adhesion, and purity.

Understanding the Trade-offs and Variations

While powerful, the PECVD process is not without its complexities and requires careful consideration of the application.

The Challenge of Plasma Damage

The same ion bombardment that improves film density can also be a source of damage. For extremely delicate substrates, such as sensitive semiconductor devices, the high energy of the plasma can introduce defects and harm the underlying material.

Direct vs. Remote PECVD

To mitigate the risk of plasma damage, a variation called Remote PECVD can be used. In this method, the plasma is generated in a separate chamber and the reactive species are transported to the substrate, which is kept in a plasma-free region. This separates the benefits of plasma activation from the potentially damaging effects of direct ion bombardment.

Making the Right Choice for Your Goal

Selecting the correct deposition strategy depends entirely on the material properties of your substrate and the desired characteristics of your final film.

- If your primary focus is coating heat-sensitive materials (like polymers): PECVD is the clear choice over thermal CVD due to its low-temperature operation.

- If your primary focus is achieving maximum film density and adhesion: Standard (direct) PECVD is highly effective, as ion bombardment enhances the film's physical properties.

- If your primary focus is depositing a film on an extremely delicate electronic substrate: Remote PECVD should be considered to prevent plasma-induced damage to the underlying components.

Ultimately, PECVD's ability to decouple the reaction energy from thermal heat makes it one of the most versatile and essential tools in modern materials science.

Summary Table:

| Key Aspect | PECVD Process | Traditional CVD Process |

|---|---|---|

| Energy Source | Plasma (RF) | Thermal (High Heat) |

| Temperature | Low (Suitable for sensitive substrates) | High (Can damage sensitive materials) |

| Film Quality | Denser, purer films with better adhesion | Standard film properties |

| Substrate Compatibility | Plastics, polymers, electronics | High-temperature resistant materials only |

Ready to enhance your thin-film deposition capabilities? KINTEK specializes in advanced lab equipment and consumables for precise PECVD applications. Our solutions help you achieve superior film quality on even the most temperature-sensitive substrates. Contact us today to discuss how our expertise can optimize your laboratory's performance and expand your material processing options!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings