In short, the environmental impact of pyrolysis is not fixed; it is a direct result of how the technology is applied. When executed responsibly, pyrolysis is a powerful tool for environmental benefit, converting waste into renewable energy and stable carbon. However, its positive potential is entirely dependent on sustainable feedstock sourcing and well-controlled operational processes.

Pyrolysis presents a significant environmental opportunity, but it is not a guaranteed solution. Its true value lies in its ability to transform low-value waste streams into high-value products like biochar for carbon sequestration. The critical challenge is ensuring the entire lifecycle—from biomass collection to final product use—is managed sustainably.

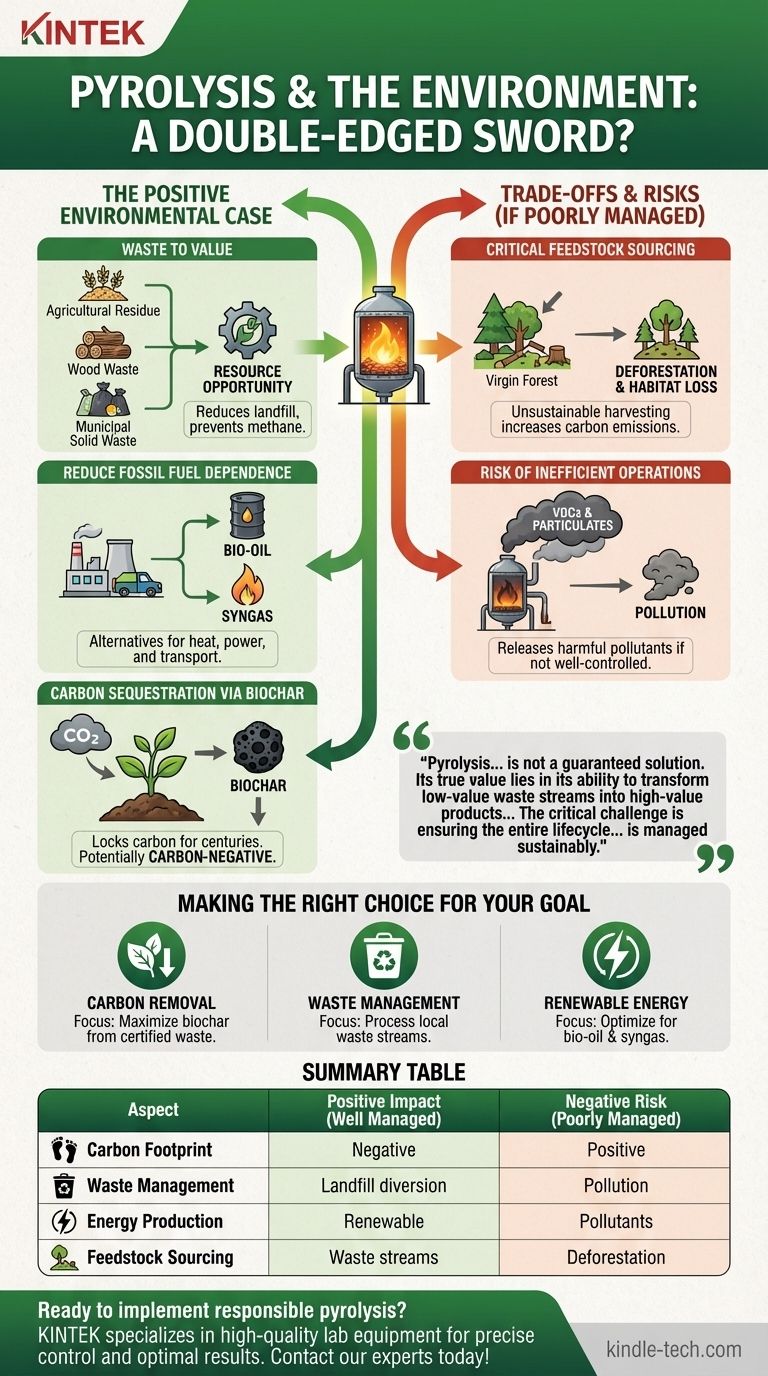

The Positive Environmental Case for Pyrolysis

Pyrolysis is a thermochemical process that heats organic materials, like biomass, at high temperatures in the absence of oxygen. This process breaks down the material into several valuable, environmentally friendly products instead of just burning it.

Converting Waste into Value

A primary benefit of pyrolysis is its ability to process materials that would otherwise end up in landfills or be openly burned. This includes agricultural residues, wood processing waste, and even certain components of municipal solid waste.

This conversion turns a disposal problem into a resource opportunity, reducing landfill burden and preventing the release of methane, a potent greenhouse gas from decomposing organic waste.

Reducing Fossil Fuel Dependence

Pyrolysis produces two key energy products: bio-oil and syngas. Bio-oil is a high-energy-density liquid that can be refined into transportation fuels or used for heat and power generation.

Syngas, a mixture of hydrogen and carbon monoxide, is a combustible gas that can be used to power the pyrolysis process itself, making it energy self-sufficient, or to generate electricity. Both products serve as direct alternatives to fossil fuels.

Carbon Sequestration via Biochar

Perhaps the most significant environmental benefit comes from biochar, a stable, carbon-rich solid similar to charcoal. When biomass grows, it absorbs atmospheric carbon dioxide (CO2).

When that biomass is converted to biochar and applied to soil, that carbon is locked away for hundreds or even thousands of years. This process, known as carbon sequestration, effectively removes CO2 from the atmosphere, making pyrolysis a potentially carbon-negative technology.

Understanding the Trade-offs and Risks

The benefits of pyrolysis are compelling, but they are not automatic. Realizing its positive potential requires careful management of significant risks that can undermine or even reverse its environmental value.

The Critical Role of Feedstock Sourcing

The entire environmental calculus of pyrolysis hinges on its input material, or feedstock. If it utilizes genuine waste streams, the benefits are clear.

However, if demand for biomass leads to the harvesting of virgin forests or the use of purpose-grown crops that displace food agriculture, the result can be deforestation, habitat destruction, and a net increase in carbon emissions. The process is only as sustainable as its source.

The Risk of Inefficient Operations

A well-designed and properly managed pyrolysis system captures and utilizes its outputs cleanly. The technology is robust and has good environmental performance characteristics.

However, a poorly controlled or inefficient process can lead to the release of harmful pollutants, such as volatile organic compounds (VOCs) and particulates. The "clean energy" label is only earned through high operational standards.

Making the Right Choice for Your Goal

To determine if pyrolysis is the right environmental strategy, you must first define your primary objective.

- If your primary focus is carbon removal: Prioritize systems designed to maximize biochar output from certified waste biomass, as this offers the most direct path to long-term carbon sequestration.

- If your primary focus is waste management: Target pyrolysis applications that can process local agricultural, forestry, or municipal waste, turning a liability into a source of energy and soil amendments.

- If your primary focus is renewable energy: Concentrate on technologies optimized for producing high-quality bio-oil and syngas to directly displace fossil fuels in heating, power, or transport.

Ultimately, pyrolysis is a technology whose environmental promise is unlocked only through deliberate and responsible implementation.

Summary Table:

| Aspect | Positive Impact (When Managed Well) | Negative Risk (When Poorly Managed) |

|---|---|---|

| Carbon Footprint | Carbon-negative via biochar sequestration | Net increase from unsustainable feedstock |

| Waste Management | Diverts biomass from landfills, reduces methane | Can create pollution from inefficient operations |

| Energy Production | Generates renewable bio-oil & syngas | Risk of releasing VOCs and particulates |

| Feedstock Sourcing | Uses genuine waste streams (e.g., agricultural residue) | Can lead to deforestation or habitat loss |

Ready to implement a responsible pyrolysis process in your laboratory? KINTEK specializes in high-quality lab equipment and consumables for pyrolysis research and development. Our reliable systems help you achieve precise control over your process, ensuring optimal biochar yield and clean energy production while minimizing environmental risks. Contact our experts today to discuss how our solutions can support your sustainable waste conversion and carbon sequestration goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Graphite Vacuum Continuous Graphitization Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the different types of pyrolysis machines? Choose the Right System for Your Output