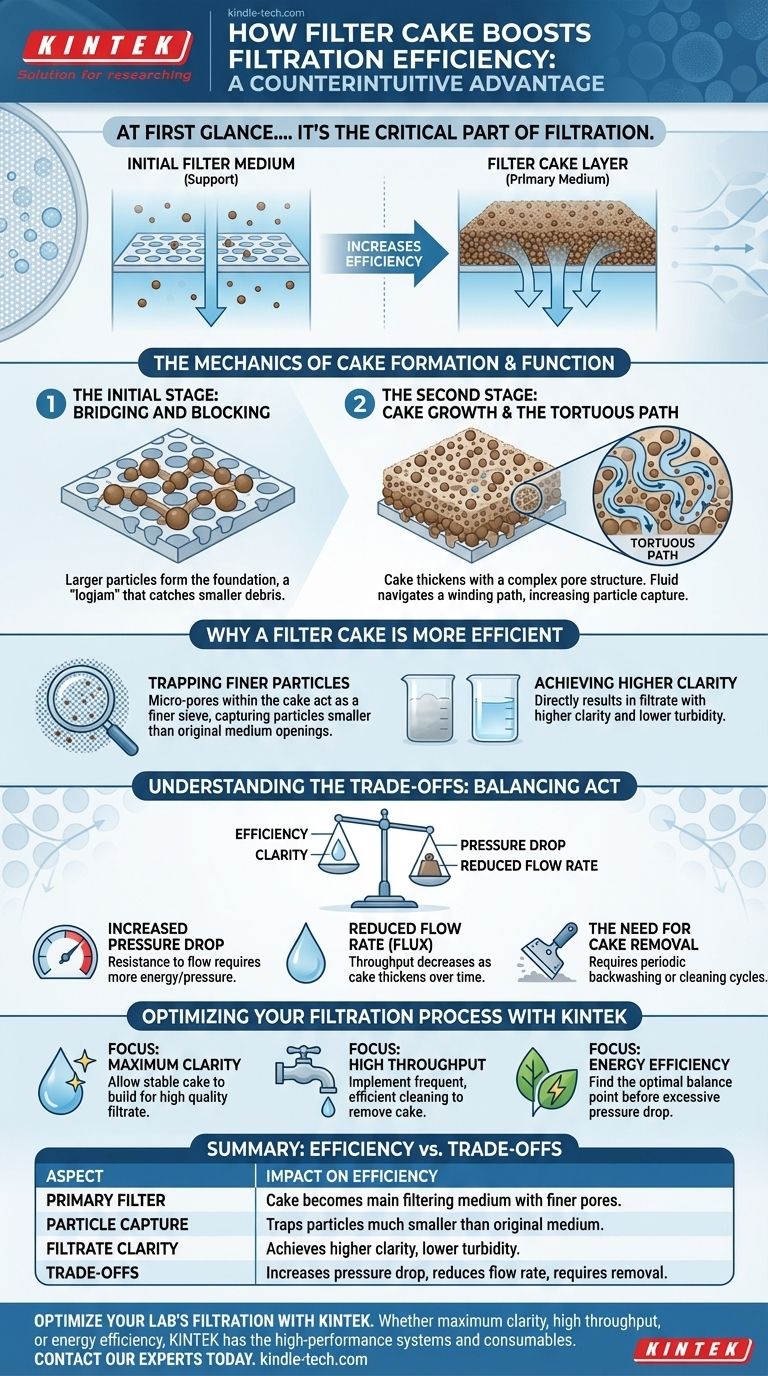

At first glance, it seems counterintuitive, but the buildup of solids on a filter is often the most critical part of the filtration process. A filter cake increases efficiency because this newly formed layer of collected particles itself becomes the primary filtering medium. The cake typically has a much finer and more complex pore structure than the underlying filter cloth or screen, enabling it to capture extremely small particles that the initial medium would otherwise let pass.

The core principle to understand is that the initial filter medium (like a cloth or screen) serves mainly as a support structure. The actual high-efficiency filtration is performed by the filter cake—the layer of solid particles that builds upon that support—which creates a denser, more intricate barrier.

The Mechanics of How a Filter Cake Works

To appreciate its efficiency, you must first understand how a filter cake forms and functions. The process is not instantaneous but evolves in distinct stages.

The Initial Stage: Bridging and Blocking

Initially, larger particles in the fluid cannot pass through the openings in the filter medium. They get stuck, forming "bridges" over the pores. This initial layer is crucial; it establishes the foundation for the rest of the cake.

Think of it like a logjam in a river. The first few large logs that get snagged create a barrier that then catches smaller branches, leaves, and silt, which couldn't have been stopped by the riverbanks alone.

The Second Stage: Cake Growth

Once this initial bridge is formed, subsequent particles no longer interact directly with the filter medium. Instead, they deposit onto the layer of already-captured solids.

This layer-by-layer growth is what builds the filter cake. The cake thickens as more fluid is passed through, and its structure becomes more complex.

How the Cake Becomes the Primary Filter

The true effectiveness of the cake comes from its tortuous path. The spaces between the collected particles are much smaller, more numerous, and more irregular than the pores of the support medium.

A fluid particle must navigate a winding, labyrinthine path to get through the cake. This greatly increases the probability that any suspended solids will collide with and adhere to the cake particles.

Why a Filter Cake Is More Efficient

The structure created during cake formation directly leads to a higher degree of separation and a cleaner output fluid (filtrate).

Trapping Finer Particles

The most significant advantage is the ability to capture particles that are orders of magnitude smaller than the openings in the original filter medium. The micro-pores within the cake act as a much finer sieve.

This is why a filter's performance often appears to improve in the initial minutes or hours of operation as the cake establishes itself.

Achieving Higher Clarity

The direct result of trapping finer particles is a filtrate with higher clarity and lower turbidity. In many industrial and chemical processes, achieving a specific level of clarity is the primary goal, making the filter cake an essential part of the process.

Understanding the Trade-offs

While highly efficient, a filter cake is not without its operational downsides. Acknowledging these trade-offs is key to managing any real-world filtration system.

Increased Pressure Drop

The most significant trade-off is resistance to flow. A thick, dense filter cake that is very good at capturing particles is also very good at obstructing the flow of fluid.

To maintain a constant flow rate, you must progressively increase the pressure, which requires more energy and puts more stress on the equipment. This is known as pressure drop.

Reduced Flow Rate (Flux)

If you operate at a constant pressure, the flow rate (or flux) will inevitably decrease as the filter cake thickens. The process slows down over time.

This creates a constant tension between achieving high filtrate quality (which requires a developed cake) and maintaining high throughput (which is hindered by the cake).

The Need for Cake Removal

A filter cake cannot build up indefinitely. Eventually, the pressure required will be too high, or the flow rate will be too low to be practical.

At this point, the filtration process must be stopped, and the cake must be removed. This is often done through backwashing, mechanical scraping, or other cleaning cycles, which represent downtime for the operation.

Optimizing Your Filtration Process

Understanding this dynamic allows you to control your filtration process based on your specific goal. The "best" approach depends entirely on what you are trying to achieve.

- If your primary focus is maximum filtrate clarity: You should allow a stable filter cake to build and operate in a mode that protects it, accepting that flow rates will be lower.

- If your primary focus is high throughput (flow rate): You must implement frequent and efficient cleaning cycles to remove the cake before its resistance becomes too high.

- If your primary focus is energy efficiency: You need to find the optimal balance point where the cake is effective enough for your quality target but is removed before the pressure drop leads to excessive energy consumption.

By treating the filter cake not as a nuisance but as a dynamic and controllable tool, you gain precise command over your filtration outcomes.

Summary Table:

| Aspect | Impact on Efficiency |

|---|---|

| Primary Filter | The cake itself becomes the main filtering medium, with finer pores than the initial support. |

| Particle Capture | Traps particles much smaller than the original filter medium's openings. |

| Filtrate Clarity | Achieves higher clarity and lower turbidity by blocking fine solids. |

| Trade-offs | Increases pressure drop and reduces flow rate over time, requiring periodic removal. |

Optimize your lab's filtration process with KINTEK. Whether you need maximum clarity, high throughput, or energy-efficient operations, the right equipment makes all the difference. KINTEK specializes in high-performance lab filtration systems and consumables designed to harness the power of filter cake dynamics. Contact our experts today to find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Versatile PTFE Solutions for Semiconductor and Medical Wafer Processing

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Laboratory CVD Boron Doped Diamond Materials

- Polyethylene Separator for Lithium Battery

People Also Ask

- What can carbon nanotubes be used for? Unlock Superior Performance in Batteries & Materials

- What instrument is used to measure vacuum? Selecting the Right Gauge for Your Pressure Range

- How do you maintain vacuum pressure? Master the balance between gas removal and gas load for stable performance.

- What are the units for vacuum pressure? Torr, mbar, and Pascal Explained

- What are the different types of ovens in the lab? A Guide to Choosing the Right Heating Equipment