Vacuum calibration is the process of comparing a vacuum gauge's reading to a known, highly accurate reference standard. This procedure verifies that the gauge is measuring pressure correctly across its operational range, ensuring the accuracy, reliability, and repeatability of your entire vacuum system. It is a critical step in any process where specific vacuum levels must be achieved and maintained.

The core purpose of vacuum calibration is to establish a chain of trust. It ensures that the pressure reading on your screen is a true and defensible representation of the physical conditions within your system, traceable back to a national or international standard.

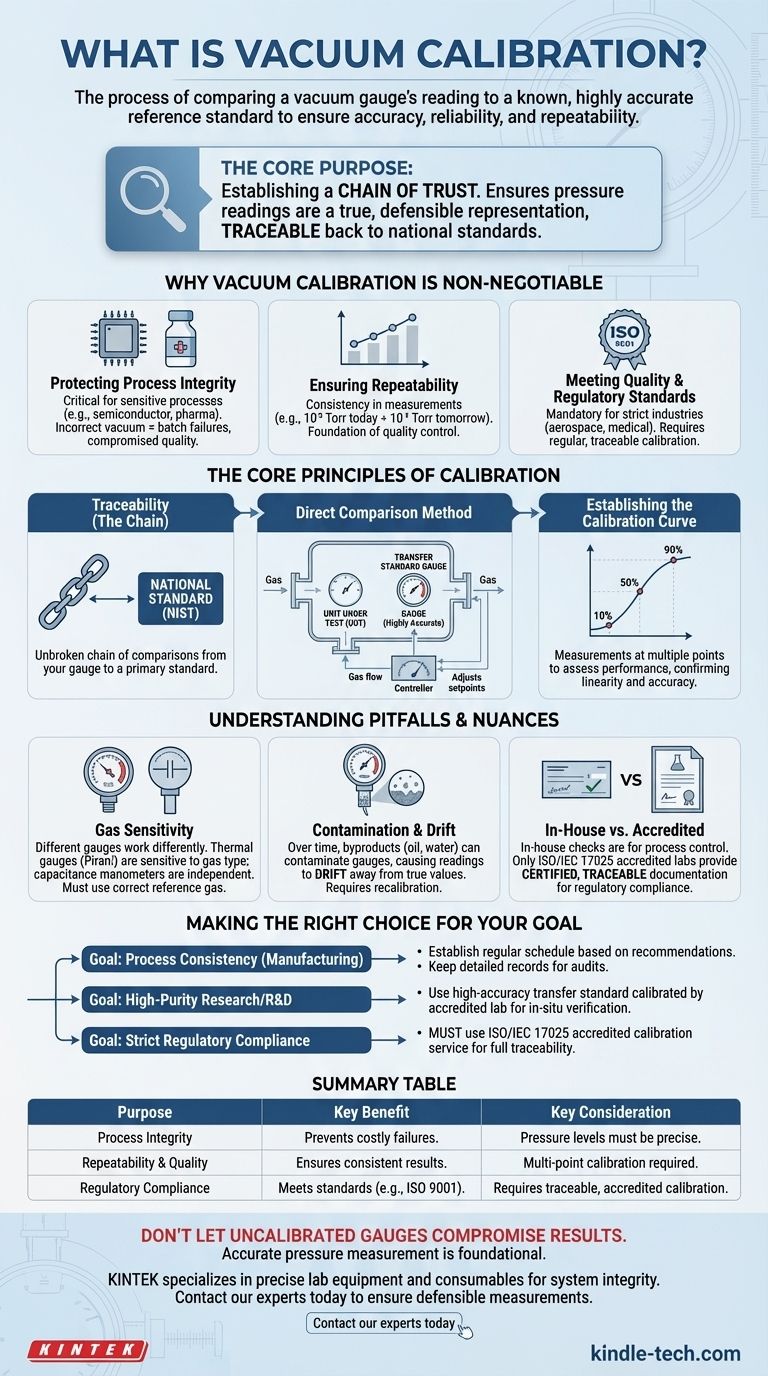

Why Vacuum Calibration is Non-Negotiable

For any critical process, an uncalibrated gauge is simply an indicator, not a measurement instrument. Its readings cannot be trusted, introducing significant risk to product quality, research outcomes, and operational safety.

Protecting Process Integrity

Many advanced industrial and scientific processes are acutely sensitive to pressure. In semiconductor manufacturing, pharmaceuticals, or aerospace component testing, an incorrect vacuum level can lead to costly batch failures, compromised product quality, or misleading research data.

Ensuring Repeatability

Calibration ensures that a vacuum level of 10⁻⁶ Torr is the same today as it was last month and will be next year. This consistency is the foundation of quality control, allowing you to produce identical results over time and across different equipment.

Meeting Quality and Regulatory Standards

Industries like aerospace, medical devices, and pharmaceuticals operate under strict quality systems (e.g., ISO 9001) and regulatory oversight. These standards mandate regular, traceable calibration of all critical measurement equipment, and vacuum gauges are no exception.

The Core Principles of Calibration

Vacuum calibration is a formal, methodical process rooted in the science of metrology. It's not simply a quick check; it's a rigorous comparison against a known benchmark.

The Concept of Traceability

Traceability is the cornerstone of all credible calibration. It means your gauge's accuracy is linked back to a primary national standard (such as those maintained by NIST in the U.S.) through an unbroken chain of comparisons. An accredited lab calibrates its reference standards against even higher-accuracy standards, which are in turn calibrated against the national standard. This creates a documented, hierarchical "calibration chain."

Direct Comparison Method

The most common method involves placing the gauge being tested, known as the Unit Under Test (UUT), and a highly accurate Transfer Standard Gauge into the same vacuum chamber. The pressure in the chamber is adjusted to various setpoints across the UUT's range, and the readings from both gauges are recorded and compared.

Establishing the Calibration Curve

Calibration is rarely a single-point check. The process involves taking measurements at multiple pressure points (e.g., 10%, 50%, and 90% of the full scale) to assess the gauge's performance. The results generate a report that shows the UUT's error at each point, confirming its linearity and accuracy across its entire working range.

Understanding the Pitfalls and Nuances

Effective calibration requires understanding that a vacuum is not a monolithic entity. Different gauges work in different ways, and environmental factors can compromise accuracy.

Gas Sensitivity and Gauge Type

Different vacuum gauges measure pressure using different physical principles. A thermal conductivity gauge (Pirani) is sensitive to the type of gas being measured, as its reading depends on the gas's ability to conduct heat. In contrast, a capacitance manometer measures direct force on a diaphragm and is independent of the gas type. Calibration must use the correct reference for the gas being used in the process (typically nitrogen).

Contamination and Gauge Drift

Over time, vacuum gauges can become contaminated with process byproducts like oil vapors, water, or other residues. This contamination can alter the gauge's internal mechanics or sensor surfaces, causing its readings to drift away from their true value. This drift is a primary reason why regular recalibration is essential.

In-House Checks vs. Accredited Calibration

Performing periodic in-house comparisons against a local reference standard is a good practice for process control. However, it does not replace the need for formal calibration by an ISO/IEC 17025 accredited laboratory. Only an accredited lab can provide the certified, traceable documentation required for regulatory compliance and absolute confidence in your measurements.

Making the Right Choice for Your Goal

Implementing a sound calibration strategy depends on your specific application and its tolerance for error.

- If your primary focus is process consistency in manufacturing: Establish a regular calibration schedule based on manufacturer recommendations and process sensitivity, and keep detailed records for quality audits.

- If your primary focus is high-purity research or R&D: Use a high-accuracy transfer standard (like a capacitance manometer) calibrated by an accredited lab and use it to periodically verify your process gauges in-situ.

- If your primary focus is meeting strict regulatory compliance: You must use an ISO/IEC 17025 accredited calibration service to ensure a fully documented and unbroken chain of traceability.

Ultimately, a disciplined approach to vacuum calibration transforms your gauges from mere indicators into trusted instruments that guarantee the integrity of your work.

Summary Table:

| Purpose | Key Benefit | Key Consideration |

|---|---|---|

| Process Integrity | Prevents costly failures in sensitive processes (e.g., semiconductors, pharmaceuticals). | Pressure levels must be precise and reliable. |

| Repeatability & Quality | Ensures consistent results over time, forming the basis of quality control. | Requires calibration at multiple points across the gauge's range. |

| Regulatory Compliance | Mandatory for meeting standards like ISO 9001 in regulated industries. | Requires traceable calibration from an accredited lab (e.g., ISO/IEC 17025). |

Don't let uncalibrated vacuum gauges compromise your results. Accurate pressure measurement is foundational to the success of your laboratory or manufacturing process. KINTEK specializes in providing the precise lab equipment and consumables you need to maintain system integrity. Our expertise ensures your vacuum systems perform reliably, supporting quality control and regulatory compliance.

Contact our experts today to discuss your vacuum calibration needs and ensure your measurements are always defensible.

Visual Guide

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What function does a vacuum environment serve in a high-temperature furnace? Protect Fe-Si Alloy Thermal Cycle Tests

- What is full brazing process? Achieve Strong, Permanent Metal Joints with Precision

- Why is a vacuum drying oven necessary for Li2MnSiO4 processing? Ensure High Purity & Battery Performance

- What are the applications of sintering process? Fabricate Complex Parts with High-Performance Materials

- What are the disadvantages of vacuum hardening? Weighing the Costs and Limitations of Precision Heat Treatment

- What are the different types of annealing in semiconductors? A Guide to Choosing the Right Thermal Process

- Why is a high vacuum brazing furnace necessary for nickel-based alloys? Achieve Oxidation-Free, High-Strength Joints

- What is the importance of leakage in a vacuum system? Prevent Contamination and Process Failure