Vacuum pressure is measured by quantifying the density of remaining gas particles in a sealed volume relative to the surrounding atmospheric pressure. Because a perfect vacuum (a complete absence of matter) is physically unachievable, measurement focuses on determining how close a system is to that ideal state, using various types of specialized gauges.

The central takeaway is that there is no single instrument for measuring all levels of vacuum. The correct measurement technique depends entirely on the specific pressure range you are operating in, shifting from direct mechanical methods for rough vacuums to indirect electronic methods for high and ultra-high vacuums.

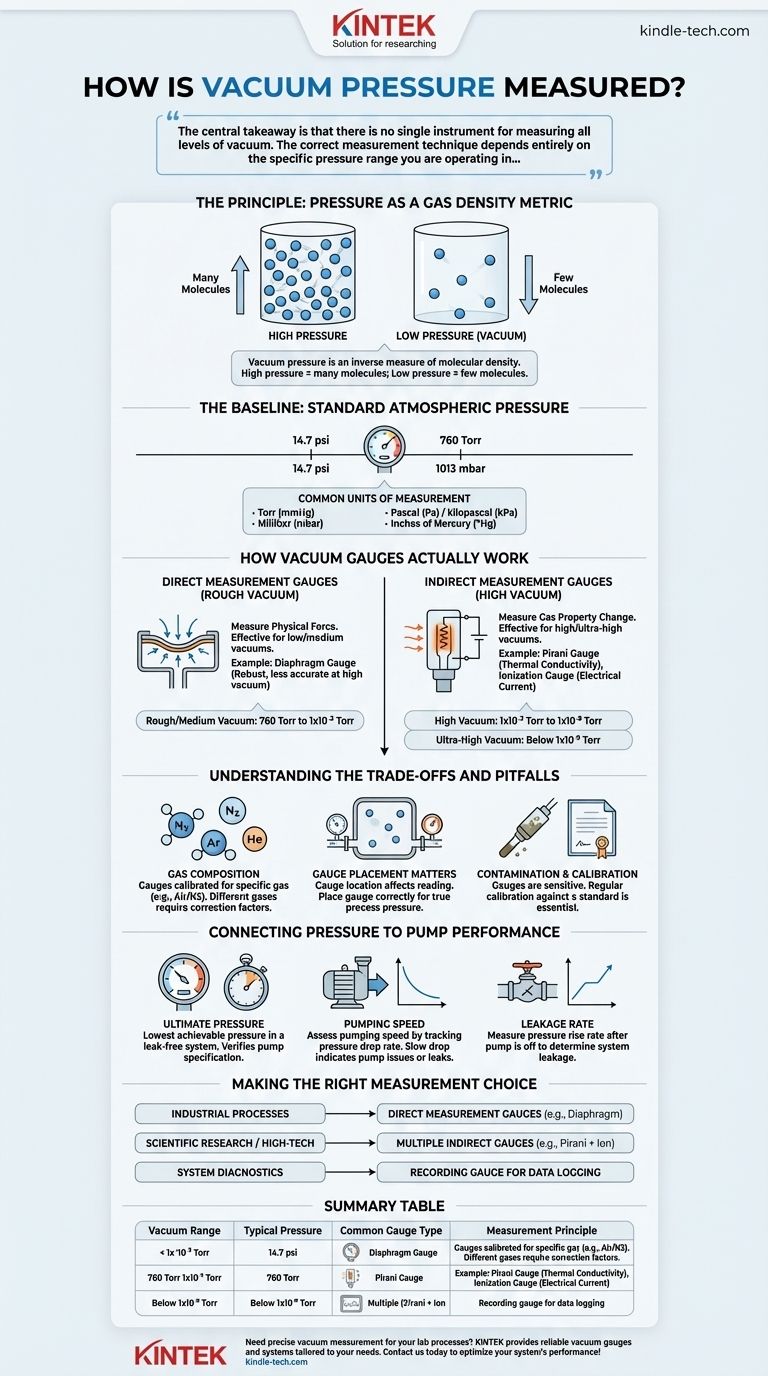

The Principle: Pressure as a Gas Density Metric

Understanding how vacuum is measured begins with a shift in perspective. Instead of thinking about suction, think about the number of gas molecules remaining in a space.

What "Vacuum Pressure" Really Means

In simple terms, vacuum pressure is an inverse measure of molecular density. High pressure means many gas molecules are present and colliding with surfaces, while low pressure (a high vacuum) means very few molecules are present.

The goal of a vacuum pump is not to "suck," but to physically remove molecules from a sealed chamber, thereby reducing the pressure inside.

The Baseline: Standard Atmospheric Pressure

All vacuum measurements are relative to a starting point. That point is the ambient atmospheric pressure, which is approximately 14.7 psi, 760 Torr, or 1013 millibars (mbar) at sea level. A vacuum reading indicates how far below this baseline the system's pressure has dropped.

Common Units of Measurement

You will encounter several units for vacuum pressure, each common in different industries or regions:

- Torr: Named after Torricelli, it's roughly equal to 1 millimeter of mercury (mmHg).

- Millibar (mbar): A common metric unit, where 1013 mbar is standard atmospheric pressure.

- Pascal (Pa): The SI unit for pressure. It's a very small unit, so kilopascals (kPa) are often used.

- Inches of Mercury ("Hg): Frequently used in the United States for industrial and HVAC applications.

How Vacuum Gauges Actually Work

The method for measuring pressure changes dramatically as the number of gas molecules decreases. Gauges are therefore split into two primary categories.

Direct Measurement Gauges (Rough Vacuum)

These gauges work by measuring the physical force exerted by gas molecules. They are effective for low to medium vacuums where enough molecules exist to create a measurable force.

A common example is a diaphragm gauge, where the gas pressure causes a flexible membrane to deflect. This mechanical movement is then converted into a pressure reading. These gauges are robust but lose accuracy as the vacuum gets stronger (fewer molecules).

Indirect Measurement Gauges (High Vacuum)

When the vacuum becomes very high, there are too few molecules to exert a measurable physical force. Indirect gauges solve this by measuring a gas property that changes predictably with pressure.

The Pirani gauge, for example, measures the thermal conductivity of the gas. A heated wire filament inside the gauge cools faster when more gas molecules are present to carry heat away. By measuring the wire's temperature, the gauge can infer the pressure.

For even higher vacuums, an ionization gauge is used. It ionizes the few remaining gas molecules and measures the resulting electrical current. A lower current corresponds to fewer molecules and therefore a higher vacuum.

Understanding the Trade-offs and Pitfalls

Accurate vacuum measurement is not as simple as attaching a gauge and reading a number. Several factors can lead to incorrect readings.

The Problem of Gas Composition

Indirect gauges are typically calibrated for a specific gas, like dry air or nitrogen. If you introduce a different gas (like argon or helium), which has different thermal or ionization properties, the gauge reading will be inaccurate unless a correction factor is applied.

Gauge Placement Matters

A gauge placed right at the inlet of a powerful vacuum pump will show a lower pressure than one placed on the far side of the chamber. To get a true reading of your process environment, the gauge must be placed correctly within the vacuum chamber itself.

Contamination and Calibration

Vacuum gauges are sensitive instruments. Over time, process byproducts can contaminate the sensor, causing its readings to drift. Regular calibration against a known standard is essential for maintaining accuracy in critical applications.

Connecting Pressure to Pump Performance

The pressure a gauge reads is the ultimate indicator of your vacuum system's health and performance, directly reflecting the key parameters of your pump.

Ultimate Pressure

This is the lowest pressure your vacuum pump can achieve in a sealed, leak-free system. Your vacuum gauge is the tool you use to verify if the pump is meeting its manufacturer's specification for ultimate pressure.

Pumping Speed

While not a direct measurement, you can assess pumping speed by tracking how quickly the pressure drops on your gauge over time. A slow pump-down curve can indicate a problem with the pump or a leak in the system.

Leakage Rate

After shutting off the pump, a perfect system would hold its vacuum level indefinitely. In reality, the pressure will slowly rise. Measuring this rate of rise with a gauge is the most fundamental way to determine the leakage rate of your system.

Making the Right Measurement Choice

Selecting the correct gauge and measurement strategy is determined entirely by the requirements of your application.

- If your primary focus is industrial processes (HVAC, food packaging, drying): You need robust, reliable measurement in the rough-to-medium vacuum range, making direct measurement gauges like diaphragm gauges the practical choice.

- If your primary focus is scientific research or high-tech manufacturing (semiconductors, thin-film coating): You require high precision in the high and ultra-high vacuum ranges. A system using multiple indirect gauges (e.g., a Pirani and an ion gauge) is necessary to cover the entire operational range accurately.

- If your primary focus is system diagnostics and troubleshooting: You need to understand pressure changes over time. A recording gauge that can log data is invaluable for identifying leaks or monitoring pump performance degradation.

Ultimately, accurate vacuum measurement is the foundation of a controlled, reliable, and repeatable process.

Summary Table:

| Vacuum Range | Typical Pressure | Common Gauge Type | Measurement Principle |

|---|---|---|---|

| Rough/Medium Vacuum | 760 Torr to 1x10^-3 Torr | Diaphragm Gauge | Direct force of gas molecules |

| High Vacuum | 1x10^-3 Torr to 1x10^-9 Torr | Pirani Gauge | Thermal conductivity of gas |

| Ultra-High Vacuum | Below 1x10^-9 Torr | Ionization Gauge | Ionization current of gas molecules |

Need precise vacuum measurement for your lab processes? KINTEK specializes in lab equipment and consumables, providing reliable vacuum gauges and systems tailored to your specific pressure range and application—from industrial drying to high-tech research. Ensure accurate, repeatable results in your vacuum-dependent processes. Contact us today to discuss your vacuum measurement needs and optimize your system's performance!

Visual Guide

Related Products

- Ultra-Vacuum Electrode Feedthrough Connector Flange Power Electrode Lead for High-Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is catalytic vs thermal pyrolysis? Choosing the Right Process for Your Biomass

- What types of steel can be quenched? A Guide to Hardenable Steels for Optimal Performance

- Do you quench before tempering? Master the Essential Sequence for Strong, Durable Steel

- What materials are used in quenching? Choosing the Right Quenchant for Hardness & Toughness

- What are the disadvantages of heat treatment furnace? Uncover the Hidden Costs & Complexities

- How much heat do you need to braze? Master the Brazing Temperature Window for Strong Joints

- What are the advantages of electric arc furnace over blast furnace? Boost Efficiency & Sustainability

- What is vacuum quenching? Achieve Maximum Hardness with a Clean, Oxidation-Free Finish