The temperature of an annealing oven is not a single value but a precise target that depends entirely on the material being treated. For example, steel is typically annealed between 815-915°C (1500-1675°F), while aluminum requires a much lower temperature of 345-415°C (650-775°F), and glass is annealed around 540°C (1000°F). The correct temperature is dictated by the material's unique internal structure and the specific goal of the annealing process.

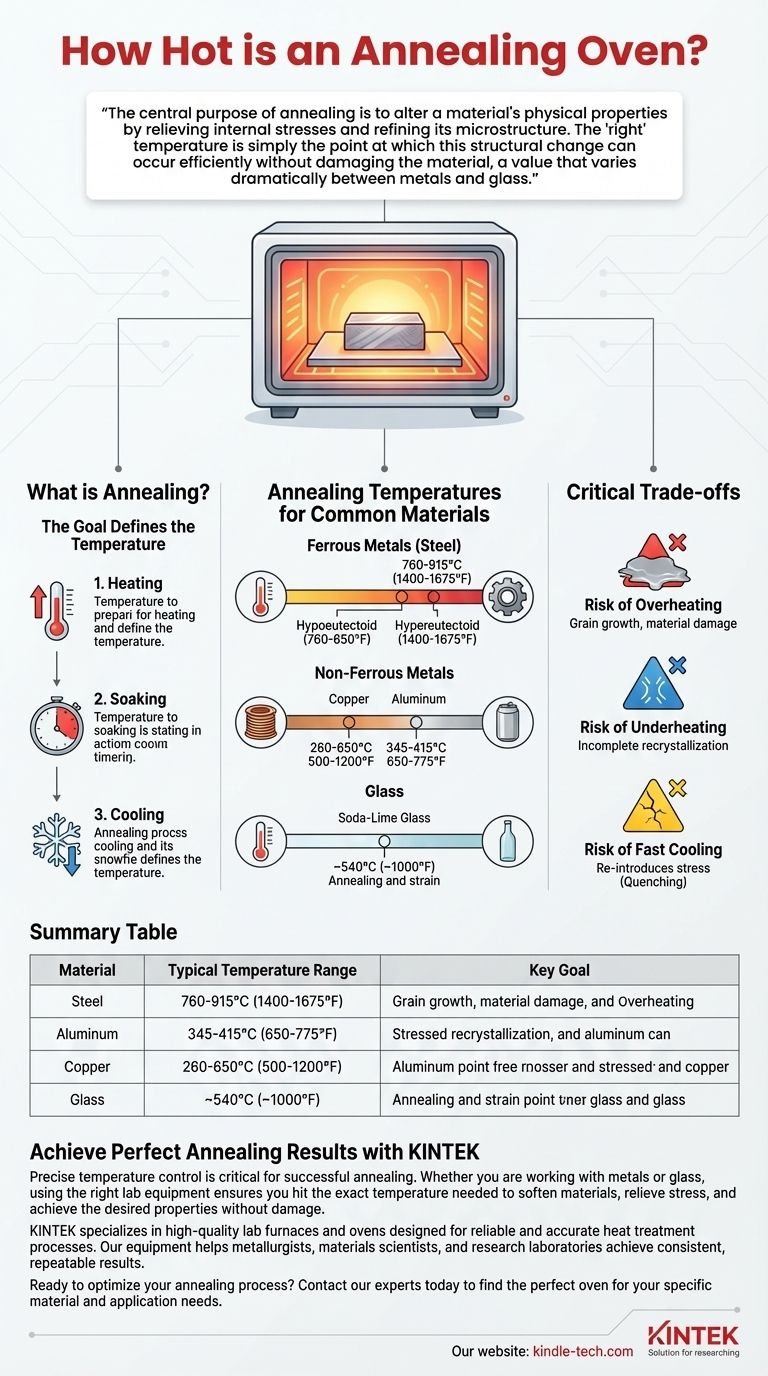

The central purpose of annealing is to alter a material's physical properties by relieving internal stresses and refining its microstructure. The "right" temperature is simply the point at which this structural change can occur efficiently without damaging the material, a value that varies dramatically between metals and glass.

What is Annealing? The Goal Defines the Temperature

Annealing is a heat treatment process used to make materials softer, more ductile (easier to shape), and less brittle. This is achieved by heating the material to a specific temperature, holding it there for a period, and then cooling it slowly.

The Purpose of Annealing

The primary goal is to undo the effects of processes like hardening, casting, or cold working (shaping a metal at room temperature). These processes create stress and dislocations within the material's crystal lattice, making it hard and brittle.

Annealing reverses this by allowing the atoms within the material to rearrange themselves into a more orderly, stress-free state. This process is known as recrystallization.

The Three Stages of the Process

Every annealing cycle consists of three critical stages, and temperature control is paramount in each.

- Heating: The material is slowly heated to the target annealing temperature to ensure a uniform temperature throughout the part.

- Soaking: The material is held at this temperature for a specific duration. This allows the internal microstructure to fully transform and relieve built-up stress.

- Cooling: The material is cooled at a very slow, controlled rate. Slow cooling is essential to prevent new stresses from forming.

Annealing Temperatures for Common Materials

Because annealing targets a specific microstructural change, the required temperature is fundamentally tied to the material's composition.

Ferrous Metals (Steel)

For carbon steels, the annealing temperature is determined by its upper critical temperature (A3 or Acm), the point at which its crystal structure transforms. The goal is to heat the steel above this point to fully refine the grain structure.

- Hypoeutectoid Steels (<0.77% Carbon): Annealed at approx. 815-915°C (1500-1675°F).

- Hypereutectoid Steels (>0.77% Carbon): Annealed at a slightly lower range of 760-840°C (1400-1550°F).

Non-Ferrous Metals (Copper, Aluminum)

These metals do not undergo the same phase transformations as steel. Here, annealing simply needs to reach the recrystallization temperature, which is often much lower.

- Copper: Typically annealed between 260-650°C (500-1200°F), depending on the alloy and degree of cold work.

- Aluminum: Fully annealed between 345-415°C (650-775°F).

Glass

Annealing glass is fundamentally different. The goal is not to soften it for working but to relieve immense internal stresses created during its initial cooling.

The glass is heated to its annealing point, a temperature where it is just soft enough for the molecular structure to relax. For common soda-lime glass, this is around 540°C (1000°F). It is then cooled extremely slowly through its strain point (approx. 510°C / 950°F), below which stress can no longer be relieved.

Understanding the Critical Trade-offs

Choosing the wrong temperature or cooling rate can render the entire process useless or even damage the material.

The Risk of Overheating

Heating a material too far above its target temperature can cause unwanted grain growth. This can make metals weaker and more brittle, defeating the purpose of annealing. In extreme cases, you risk melting the material.

The Risk of Underheating

If the material does not reach its full annealing temperature, recrystallization will be incomplete. The internal stresses will not be fully relieved, and the material will not achieve the desired softness and ductility.

The Importance of Slow Cooling

Fast cooling is the enemy of annealing. Cooling too quickly re-introduces stress into the material, a process known as quenching or hardening. For successful annealing, the material must cool slowly and uniformly, often by leaving it inside the turned-off oven.

How to Apply This to Your Goal

The correct annealing temperature is a direct function of your material and your desired outcome.

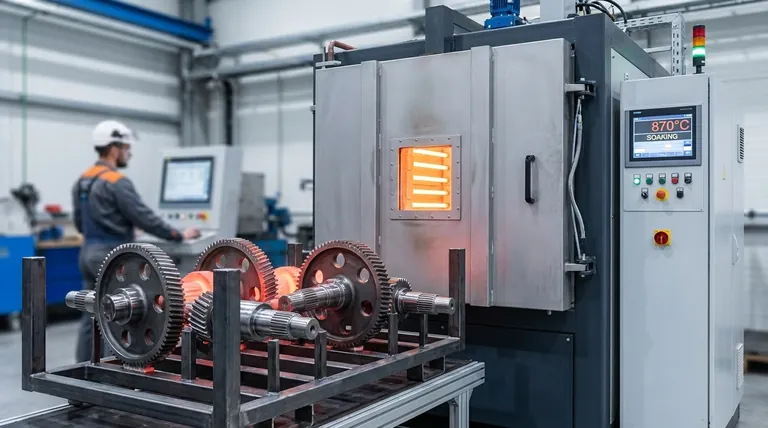

- If your primary focus is making hardened steel machinable: You must heat the steel above its upper critical temperature (e.g., ~870°C / 1600°F) to achieve a full structural reset.

- If your primary focus is softening work-hardened copper or brass: You only need to reach its lower recrystallization temperature (e.g., ~480°C / 900°F) to relieve stress before further forming.

- If your primary focus is preventing a glass object from cracking: You must heat it to its specific annealing point (~540°C / 1000°F for soda-lime) and then implement a very slow, controlled cooling ramp.

Ultimately, mastering annealing comes from understanding that temperature is the tool you use to control a material's fundamental internal structure.

Summary Table:

| Material | Typical Annealing Temperature Range | Key Goal |

|---|---|---|

| Steel | 815-915°C (1500-1675°F) | Relieve stress, soften for machining |

| Aluminum | 345-415°C (650-775°F) | Soften work-hardened material |

| Copper | 260-650°C (500-1200°F) | Recrystallize and relieve stress |

| Glass | ~540°C (~1000°F) | Relieve internal stresses to prevent cracking |

Achieve Perfect Annealing Results with KINTEK

Precise temperature control is critical for successful annealing. Whether you are working with metals or glass, using the right lab equipment ensures you hit the exact temperature needed to soften materials, relieve stress, and achieve the desired properties without damage.

KINTEK specializes in high-quality lab furnaces and ovens designed for reliable and accurate heat treatment processes. Our equipment helps metallurgists, materials scientists, and research laboratories achieve consistent, repeatable results.

Ready to optimize your annealing process? Contact our experts today to find the perfect oven for your specific material and application needs.

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Which type of metals can be melted using tilting furnace? Your Guide to Ferrous, Non-Ferrous & Precious Metals

- How long does a vacuum heat treatment cycle take? It Depends on Your Material and Part Size

- What is the heating rate range for fast pyrolysis? Maximize Your Bio-Oil Yield

- Why graphite is used in furnace? Achieve Superior Heat Treatment & Energy Efficiency

- What is the difference between calcination and sintering furnace? A Guide to Thermal Processing Goals

- Why is a vacuum drying oven essential in the fabrication of Li8/7Ti2/7V4/7O2 electrodes? Prevent Battery Degradation

- What is the sintering process of stainless steel? Transform Powder into Dense, Strong Components

- How is vacuum packing different from normal packing? A Guide to Industrial Vacuum Hardening