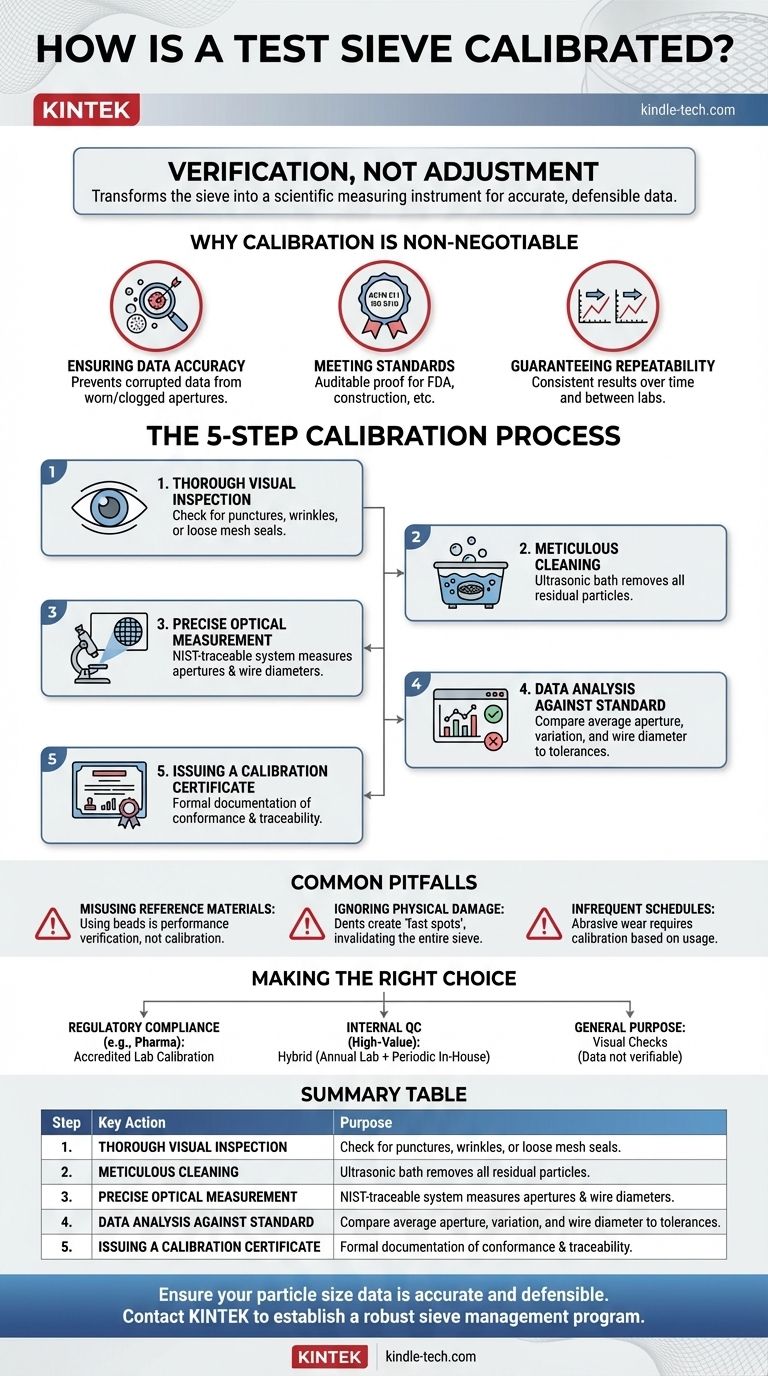

Test sieve calibration is a process of verification, not adjustment. It involves a meticulous optical examination to measure the physical characteristics of the sieve mesh—specifically the aperture openings and wire diameter—and compares them against the precise tolerances defined by industry standards like ASTM E11 or ISO 3310. This process certifies that the sieve will perform as expected, ensuring the accuracy of particle size analysis.

The core purpose of calibrating a test sieve is to generate objective, traceable proof that its physical structure conforms to a recognized standard. This transforms the sieve from a simple screen into a scientific measuring instrument, guaranteeing that the data you collect is accurate, repeatable, and defensible.

Why Sieve Calibration is Non-Negotiable

A test sieve that is out of specification is not a tool; it's a source of error. Proper calibration is the foundation of reliable particle size analysis for several critical reasons.

Ensuring Data Accuracy

The entire purpose of a sieve is to separate particles by size. If the apertures are worn, stretched, or clogged, they will retain particles they should pass or pass particles they should retain. This directly corrupts your measurement data, leading to incorrect conclusions about your material.

Meeting Industry and Regulatory Standards

Many industries, from pharmaceuticals (FDA) to construction materials and geology, operate under strict quality standards. ASTM E11 (in North America) and ISO 3310-1 (international) are the primary standards that define the permissible variations in aperture size and wire diameter for a given sieve designation.

Calibration provides the auditable documentation required to prove compliance with these standards.

Guaranteeing Repeatability and Reproducibility

Calibration ensures that a test performed today will yield the same results as one performed six months from now (repeatability). It also ensures that results from your lab will correlate with results from a different lab using a properly calibrated sieve stack (reproducibility).

The Calibration Process: A Step-by-Step Verification

Calibrating a sieve is a formal, multi-step process typically performed by an accredited laboratory with specialized equipment.

Step 1: Thorough Visual Inspection

Before any measurements are taken, the sieve is examined for gross defects. This includes checking for punctures, wrinkles, or sagging in the mesh, as well as ensuring the mesh is taut and uniformly sealed to the frame. A damaged frame or a loose mesh seal can compromise the test.

Step 2: Meticulous Cleaning

The sieve must be perfectly clean. Any residual particles lodged in the mesh will obscure the apertures and lead to inaccurate measurements. An ultrasonic bath is the standard method for ensuring all openings are clear.

Step 3: Precise Optical Measurement

This is the heart of the calibration. The sieve is placed on a stage under a specialized, NIST-traceable optical comparator or automated video imaging system. This instrument projects a magnified view of the mesh onto a screen, allowing for extremely precise digital measurements.

Step 4: Data Analysis Against the Standard

The system measures a statistically significant number of apertures and wire diameters across the entire surface of the sieve. The analysis focuses on key criteria defined by the relevant standard (e.g., ASTM E11):

- Average Aperture Size: Is the mean opening size within the permitted range?

- Maximum Variation: Does any single opening exceed the maximum allowable size?

- Wire Diameter: Are the wires that form the mesh within the specified diameter tolerance?

Step 5: Issuing a Calibration Certificate

If the sieve meets all specifications, it is certified. A formal calibration certificate is issued, which includes the actual measurement data, a statement of conformance to the specific standard, and information on the traceability of the measurement back to a national metrology institute like NIST.

Common Pitfalls and Misconceptions

Understanding the difference between true calibration and simple performance checks is crucial for maintaining data integrity.

Misusing Reference Materials for "Calibration"

A common mistake is to use certified reference materials (like precisely sized glass beads) and assume this "calibrates" the sieve. This is a performance verification, not a calibration.

While this test can indicate a major problem, it doesn't provide the detailed physical measurements required for true certification. It tells you that a sieve might be faulty, but calibration tells you exactly how and why.

Ignoring Physical Damage

A small dent or crease in the mesh might seem insignificant, but it can distort dozens of apertures in that area, creating a "fast spot" that invalidates the entire sieve's performance. Any sieve with visible damage should be removed from service immediately.

Infrequent Calibration Schedules

Sieves wear out with use. The abrasive nature of many materials gradually widens the apertures and thins the wires. The frequency of calibration should be based on usage, with sieves used daily requiring much more frequent checks than those used weekly or monthly.

Making the Right Choice for Your Goal

Implementing a sieve management program requires matching the level of rigor to the criticality of your application.

- If your primary focus is regulatory compliance (e.g., pharmaceuticals, aerospace): You must use a third-party accredited laboratory for formal calibration and certification. There is no substitute for this level of traceability.

- If your primary focus is internal quality control for a high-value product: A hybrid approach is effective. Schedule formal third-party calibrations annually and conduct in-house performance verifications with reference materials quarterly or monthly.

- If your primary focus is general-purpose or low-impact sorting: Regular visual inspections for damage and thorough cleaning may be sufficient, but you must accept that the resulting data is not considered verifiable for quality assurance purposes.

A robust sieve calibration program transforms your particle size analysis from an estimate into a verifiable, trustworthy measurement.

Summary Table:

| Calibration Step | Key Action | Purpose |

|---|---|---|

| 1. Visual Inspection | Check for damage, wrinkles, or loose mesh. | Identify gross defects that invalidate the sieve. |

| 2. Meticulous Cleaning | Use an ultrasonic bath to remove all particles. | Ensure apertures are clear for accurate measurement. |

| 3. Optical Measurement | Use a NIST-traceable comparator to measure apertures and wire diameter. | Obtain precise, objective data on the sieve's physical state. |

| 4. Data Analysis | Compare measurements against ASTM E11 or ISO 3310 tolerances. | Certify the sieve conforms to the required standard. |

| 5. Certification | Issue a formal certificate with measurement data. | Provide auditable proof of compliance and traceability. |

Ensure your particle size data is accurate and defensible. A properly calibrated test sieve is a scientific instrument, not just a screen. KINTEK specializes in high-quality lab equipment and consumables, serving the precise needs of laboratories like yours.

Our experts can help you establish a robust sieve management program to meet your specific compliance and quality control goals. Contact KINTEK today to discuss your calibration needs and ensure the integrity of your analysis.

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Small Lab Rubber Calendering Machine

People Also Ask

- Why is a high-mesh microporous sieve used in composite geomaterials? Optimize Particle Size for Maximum Adsorption

- What are laboratory test sieves used for? A Guide to Particle Size Analysis

- What are the limitations of sieving method? Understanding Accuracy and Particle Size Challenges

- What are the uses of sieves in laboratory? Ensure Material Quality and Consistency

- What are the standard test sieves for ASTM? Ensure Accuracy with ASTM E11 Compliant Sieves

- What is sieving and how does it work? A Guide to Accurate Particle Size Analysis

- Why is a standard mesh sieving system necessary for polyester methanolysis? Ensure Precise Reaction Kinetics

- What is sieving used for in science? A Guide to Particle Size Analysis & Control