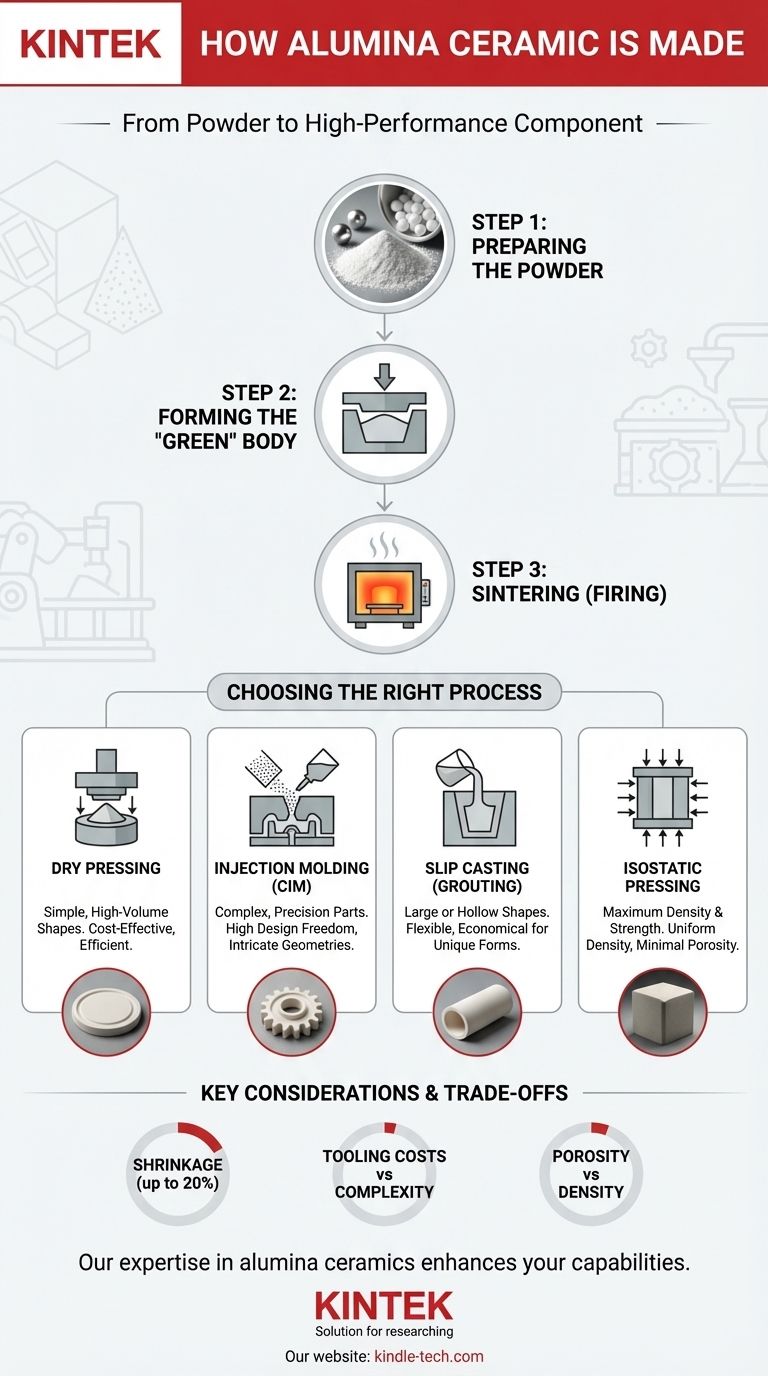

At its core, creating an alumina ceramic component involves three fundamental steps: preparing a highly pure aluminum oxide powder, compacting that powder into a desired shape (known as a "green body"), and then firing it in a furnace at extremely high temperatures. This final heating process, called sintering, fuses the powder particles together into a dense, solid, and exceptionally hard ceramic part.

The specific manufacturing method chosen is not just a detail—it is the primary factor that dictates the final part's geometric complexity, precision, and performance characteristics. Understanding the link between the forming process and the end result is critical for any technical application.

The Foundational Steps of Alumina Ceramic Production

All alumina ceramic manufacturing follows a common pathway, regardless of the final shape. Each step is carefully controlled to achieve the desired material properties.

Step 1: Preparing the Alumina Powder

The process begins with high-purity aluminum oxide (Al₂O₃) powder. This raw material is often milled and refined to create extremely fine particles of a consistent size.

The uniformity of the powder is critical, as it directly impacts how densely the final part can be packed, which in turn determines its final strength and hardness.

Step 2: Forming the "Green" Body

This is the "molding" stage, where the powder is formed into the approximate shape of the final component. This unfired, fragile piece is called a green body.

The references list several methods, each suited for different applications. The goal is to compact the powder particles as closely together as possible.

Step 3: Sintering - Firing Under Extreme Heat

The green body is placed in a high-temperature kiln or furnace for the final and most critical step: sintering.

During sintering, the part is heated to temperatures often exceeding 1600°C (2900°F). At this heat, the individual alumina particles fuse together, eliminating the pores between them and creating a single, dense, monolithic structure. This process also causes the part to shrink significantly, a factor that must be precisely calculated in the design phase.

Why So Many Forming Methods? Choosing the Right Process

The variety of molding methods exists because there is no single best way to form a ceramic part. The choice depends entirely on the part's size, shape complexity, required precision, and production volume.

For Simple, High-Volume Shapes: Dry Pressing

This method involves compacting the alumina powder in a rigid die under immense pressure. It is highly efficient and cost-effective for producing simple geometries like tiles, discs, and seals in large quantities.

For Complex, Precision Parts: Injection Molding (CIM)

For small, intricate parts, ceramic injection molding is ideal. The alumina powder is mixed with a binder to create a feedstock that can be injected into a mold, similar to plastic injection molding. This allows for complex features and high precision in mass production.

For Large or Hollow Shapes: Grouting (Slip Casting)

In this process, a liquid slurry of alumina powder and water (called a "slip") is poured into a porous mold. The mold absorbs the water, leaving a layer of solid ceramic on the mold wall. It's an effective method for creating hollow or large shapes like tubes and crucibles.

For Ultimate Density and Strength: Isostatic Pressing

Isostatic pressing applies pressure to the powder from all directions simultaneously using a fluid medium.

Cold Isostatic Pressing (CIP) creates a very uniform green body, while Hot Isostatic Pressing (HIP) combines extreme pressure and temperature to create parts with virtually no porosity, resulting in the highest possible strength and reliability.

Understanding the Trade-offs

Selecting a manufacturing process for alumina ceramic involves balancing competing priorities of cost, complexity, and performance.

Shrinkage and Dimensional Control

All sintered ceramics shrink, often by as much as 20% in each dimension. Precisely predicting and controlling this shrinkage is a primary challenge in manufacturing, especially for high-precision components. Final grinding or machining is often required to meet tight tolerances.

Tooling Costs vs. Part Complexity

Methods capable of producing complex shapes, like injection molding, require extremely expensive and precise molds. This high initial tooling cost is only justified by very high production volumes. Simpler methods like dry pressing have much lower tooling costs.

Porosity and Final Density

The primary goal of sintering is to achieve maximum density by eliminating porosity. Any remaining voids can act as stress concentrators, reducing the material's strength and durability. The forming method and sintering parameters are the key variables that control the final density of the part.

Making the Right Choice for Your Application

Your choice of manufacturing process must align directly with the primary goal for your component.

- If your primary focus is high-volume production of simple shapes: Dry pressing is almost always the most cost-effective and efficient solution.

- If your primary focus is creating small parts with high geometric complexity: Ceramic Injection Molding (CIM) offers unmatched design freedom, provided the production volume justifies the high initial tooling investment.

- If your primary focus is maximum material strength and performance for a critical application: Isostatic pressing, particularly Hot Isostatic Pressing (HIP), will produce the most dense and reliable component possible.

- If your primary focus is creating larger, hollow, or unique shapes in lower volumes: Slip casting (grouting) provides a flexible and economical path forward.

Understanding this direct link between the manufacturing process and the final material properties is the key to successfully engineering with alumina ceramics.

Summary Table:

| Manufacturing Method | Best For | Key Characteristics |

|---|---|---|

| Dry Pressing | Simple, high-volume shapes (tiles, discs) | Cost-effective, efficient for mass production |

| Ceramic Injection Molding (CIM) | Complex, precision parts | High design freedom, suitable for intricate geometries |

| Slip Casting (Grouting) | Large or hollow shapes (tubes, crucibles) | Flexible for unique shapes, economical for lower volumes |

| Isostatic Pressing (CIP/HIP) | Maximum density and strength | Uniform density, minimal porosity, highest reliability |

Need expert guidance on selecting the right alumina ceramic manufacturing process for your application? At KINTEK, we specialize in providing high-performance lab equipment and consumables, including advanced ceramic solutions. Whether you require components with exceptional hardness, thermal stability, or complex geometries, our team can help you choose the optimal method to meet your specific needs.

Contact us today to discuss your project and discover how our expertise in alumina ceramics can enhance your laboratory's capabilities and ensure the success of your application.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What temperature can silicon carbide withstand? Operating Limits from 1600°C to 2700°C

- Why is sintering important in ceramic processing? Achieve Dense, High-Performance Ceramic Parts

- What happens when ceramic is heated? A Deep Dive into Radiant Heat & Thermal Stability

- What is another name for ceramic? A Guide to Pottery, Porcelain, and Technical Materials

- How is microwave different from conventional sintering? Unlock Faster, More Efficient Material Processing

- Which is harder silicon carbide or tungsten carbide? Discover the Key to Material Selection

- What is the overview of ceramics? Unlocking the Potential of Advanced Materials

- What material is used for pusher plates? Discover Mullite's Superior Chemical and Thermal Shock Resistance