In short, Diamond-Like Carbon (DLC) is applied in a vacuum chamber using highly specialized deposition processes. The two most common industrial methods are Physical Vapor Deposition (PVD) and Plasma-Assisted Chemical Vapor Deposition (PACVD), both of which build the coating atom-by-atom onto a component's surface.

The critical takeaway is that DLC is not a paint or a plating; it is a high-performance film grown onto a surface in a controlled environment. The choice of application method is dictated by the part's geometry, the substrate material, and the specific properties required from the final coating.

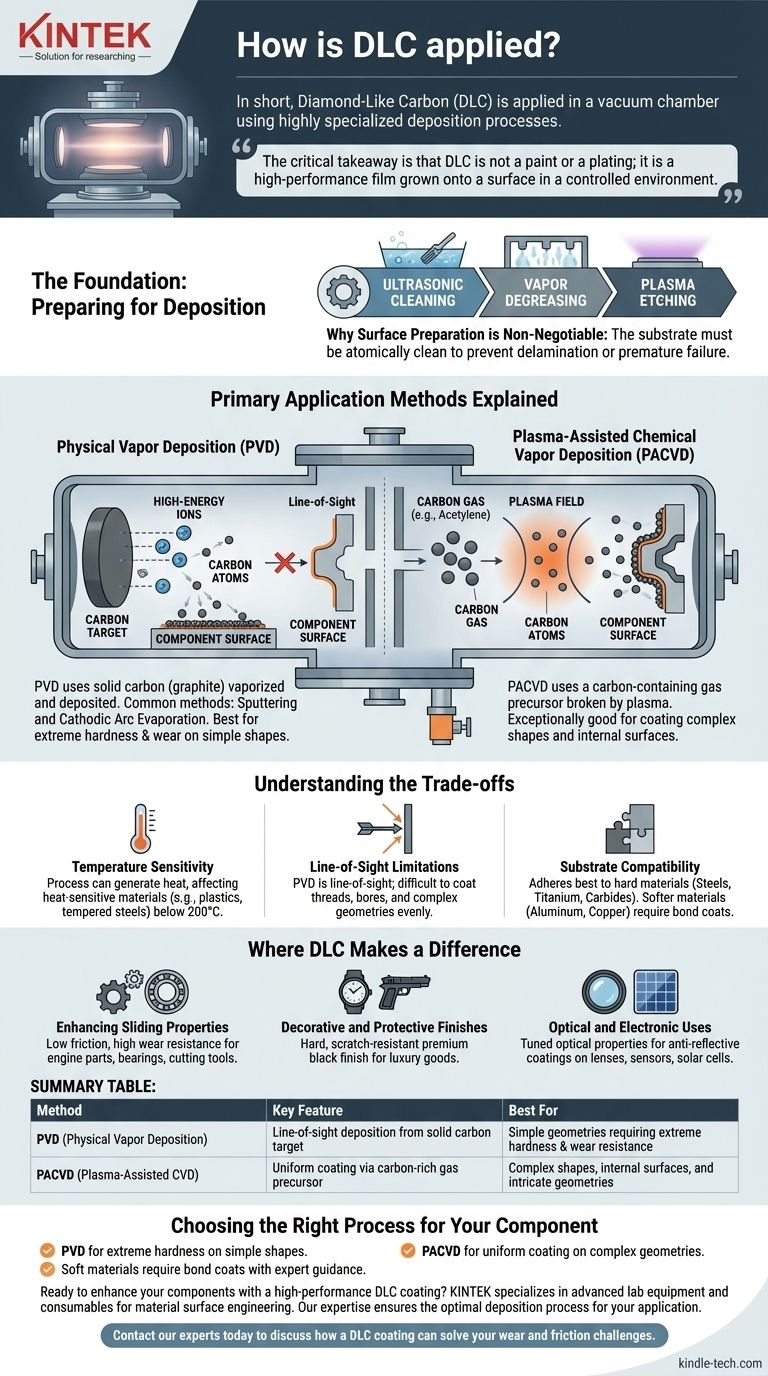

The Foundation: Preparing for Deposition

Before any coating is applied, the component's surface must be pristine. This is the most critical step for ensuring proper adhesion and performance.

Why Surface Preparation is Non-Negotiable

The substrate surface must be atomically clean. Any residue, from oils to microscopic dust, will create a weak point, causing the coating to delaminate or fail prematurely.

The process typically involves multi-stage ultrasonic cleaning baths, vapor degreasing, and sometimes plasma etching inside the coating chamber itself to remove the final layers of contaminants.

Primary Application Methods Explained

DLC coatings are formed in a vacuum using plasma, which is an ionized gas that enables the precise deposition of the carbon film.

Physical Vapor Deposition (PVD)

PVD encompasses techniques where a solid material (in this case, graphite) is vaporized and then deposited onto the component.

The most common PVD methods for DLC are sputtering and cathodic arc evaporation. In both, high-energy ions bombard a solid carbon target, knocking carbon atoms loose. These atoms then travel through the vacuum and condense on the component's surface, forming the dense DLC film.

Plasma-Assisted Chemical Vapor Deposition (PACVD)

PACVD uses a different approach. Instead of starting with a solid carbon target, this method introduces a carbon-containing gas (like acetylene) into the vacuum chamber.

A powerful plasma field is generated, which breaks the gas molecules apart. This frees the carbon atoms to deposit evenly onto the component, creating the DLC layer. Because it uses a gas precursor, PACVD is exceptionally good at coating complex shapes and internal surfaces.

Understanding the Trade-offs

Applying a DLC coating is a technical process with specific limitations that must be considered during the design phase.

Temperature Sensitivity

Both PVD and PACVD are energetic processes that generate heat. While many processes are engineered to run at lower temperatures (below 200°C), the heat can still be sufficient to affect heat-sensitive materials like certain plastics or low-temperature tempered steels.

Line-of-Sight Limitations

PVD methods are generally "line-of-sight" processes. This means the coating can only form on surfaces that have a direct path from the carbon source. This makes it difficult to uniformly coat complex geometries, threads, or internal bores.

Substrate Compatibility

DLC adheres best to hard, stable materials like steels, titanium, and carbides. Softer materials like aluminum or copper often require specialized intermediate layers (or "bond coats") to ensure the hard DLC film has a stable foundation and adheres properly.

Where DLC Makes a Difference

The unique properties of DLC make it valuable across numerous industries for both functional and aesthetic purposes.

Enhancing Sliding Properties

As the references note, a primary use is for components requiring low friction and high wear resistance. This includes engine parts like piston pins and valve lifters, bearings, and industrial cutting tools.

Decorative and Protective Finishes

DLC provides a hard, scratch-resistant surface with a premium black finish. It is often used on luxury watches, high-end firearms, and other consumer products where durability and appearance are paramount.

Optical and Electronic Uses

The specific structure of a DLC film can be tuned for optical properties. As noted, it can serve as a durable, anti-reflective coating for lenses, sensors, and even improve the efficiency of silicon solar cells.

Choosing the Right Process for Your Component

Understanding the application method is the key to successfully implementing a DLC coating.

- If your primary focus is extreme hardness and wear resistance on a simple shape: A PVD arc evaporation process is an excellent and common choice.

- If your primary focus is coating a complex geometry or internal surface: A PACVD process is superior due to its use of a precursor gas that coats more uniformly.

- If your component is made of a soft material like aluminum: You must work with your coating provider to specify the correct adhesive bond layer for a successful outcome.

Ultimately, a successful DLC application relies on matching the deposition technique to the material, geometry, and functional goal of your component.

Summary Table:

| Method | Key Feature | Best For |

|---|---|---|

| PVD (Physical Vapor Deposition) | Line-of-sight deposition from a solid carbon target | Simple geometries requiring extreme hardness & wear resistance |

| PACVD (Plasma-Assisted CVD) | Uniform coating via a carbon-rich gas precursor | Complex shapes, internal surfaces, and intricate geometries |

Ready to enhance your components with a high-performance DLC coating?

KINTEK specializes in advanced lab equipment and consumables for material surface engineering. Our expertise ensures you select the optimal deposition process (PVD or PACVD) for your specific substrate and application, guaranteeing superior hardness, wear resistance, and low friction.

Contact our experts today to discuss how a DLC coating can solve your wear and friction challenges.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained