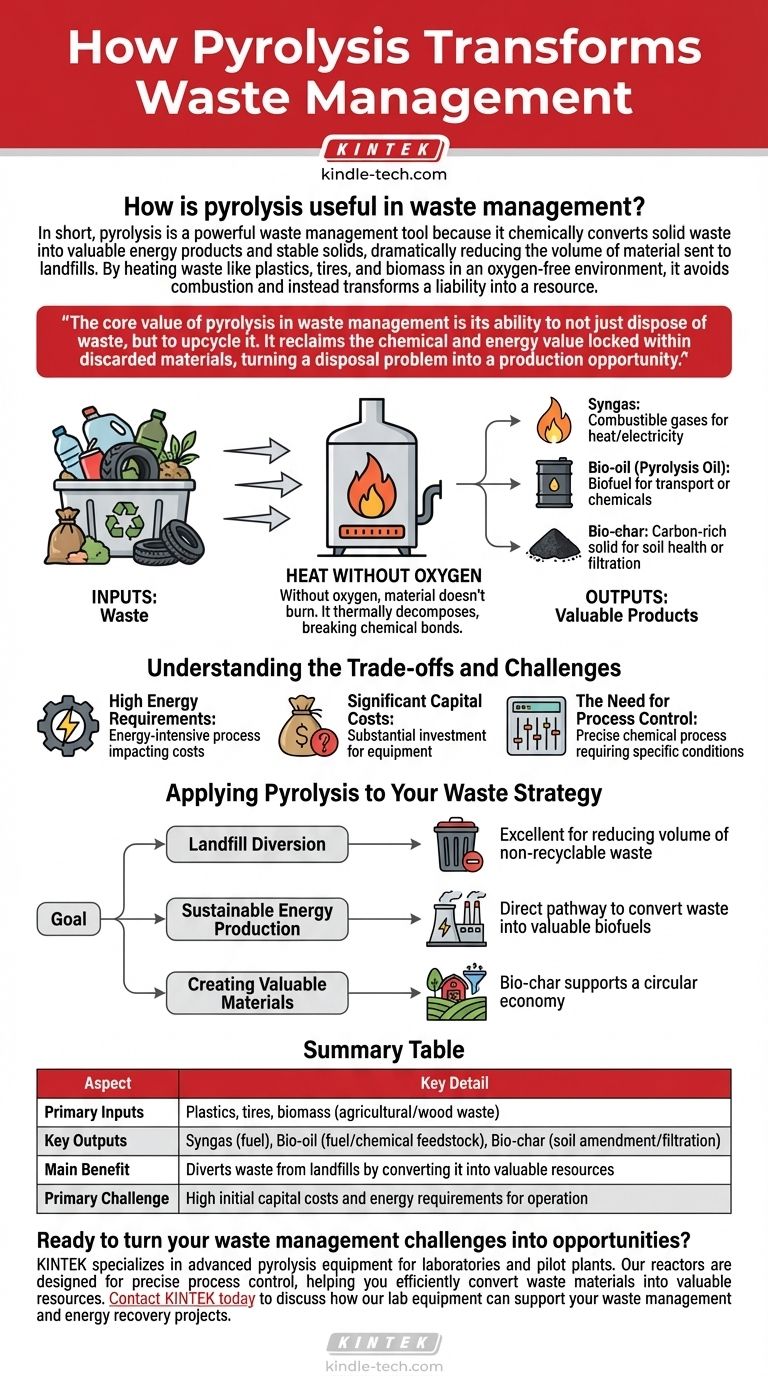

In short, pyrolysis is a powerful waste management tool because it chemically converts solid waste into valuable energy products and stable solids, dramatically reducing the volume of material sent to landfills. By heating waste like plastics, tires, and biomass in an oxygen-free environment, it avoids combustion and instead transforms a liability into a resource.

The core value of pyrolysis in waste management is its ability to not just dispose of waste, but to upcycle it. It reclaims the chemical and energy value locked within discarded materials, turning a disposal problem into a production opportunity.

How Pyrolysis Works in Waste Management

Pyrolysis is fundamentally different from incineration. Instead of burning waste, which produces ash and flue gases, it uses high heat in the absence of oxygen to break down complex materials into simpler, more valuable substances.

The Core Principle: Heat Without Oxygen

The process involves placing solid waste into a pyrolysis furnace and heating it to high temperatures. Without oxygen, the material cannot burn. Instead, it thermally decomposes, breaking its chemical bonds to form new, smaller molecules.

The Inputs: What Waste Can Be Processed?

Pyrolysis is highly effective for organic and carbon-based materials that are often difficult to recycle. Common feedstocks in waste management include:

- Plastics

- Used tires

- Biomass (agricultural waste, wood scraps)

The Outputs: From Waste to Valuable Products

The decomposition process yields three primary products, each with distinct uses.

- Syngas: A mixture of combustible gases that can be used as a fuel to generate heat or electricity.

- Bio-oil (Pyrolysis Oil): A liquid biofuel that can be refined for use as a transportation fuel or as a feedstock for the chemical industry.

- Bio-char: A stable, carbon-rich solid that can be used to improve soil health or be processed further into activated carbon for filtration.

Understanding the Trade-offs and Challenges

While promising, pyrolysis is not a perfect solution. Implementing it effectively requires a clear understanding of its operational and economic challenges.

High Energy Requirements

The process is energy-intensive. A significant amount of heat is needed to maintain the reaction, which can impact the overall energy balance and operational cost if not managed efficiently.

Significant Capital Costs

Building a pyrolysis facility requires a substantial initial investment. The specialized furnaces and equipment needed for processing, separation, and purification of the end products are expensive.

The Need for Process Control

Pyrolysis is a precise chemical process, not simple disposal. Achieving an efficient conversion and producing high-quality end products requires specific temperatures and conditions, which adds to its complexity.

Applying Pyrolysis to Your Waste Strategy

The decision to use pyrolysis depends entirely on the primary goal of the waste management initiative.

- If your primary focus is landfill diversion: Pyrolysis is an excellent method for drastically reducing the volume of non-recyclable plastics, tires, and biomass.

- If your primary focus is sustainable energy production: It serves as a direct pathway to convert solid waste into valuable biofuels like syngas and bio-oil.

- If your primary focus is creating valuable materials: The bio-char produced can be a key output for use in agriculture or advanced manufacturing, supporting a circular economy.

Ultimately, pyrolysis offers a sophisticated way to redefine waste as a valuable local resource.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Inputs | Plastics, tires, biomass (agricultural/wood waste) |

| Key Outputs | Syngas (fuel), Bio-oil (fuel/chemical feedstock), Bio-char (soil amendment/filtration) |

| Main Benefit | Diverts waste from landfills by converting it into valuable resources |

| Primary Challenge | High initial capital costs and energy requirements for operation |

Ready to turn your waste management challenges into opportunities?

KINTEK specializes in advanced pyrolysis equipment for laboratories and pilot plants. Our reactors are designed for precise process control, helping you efficiently convert waste materials like plastics, tires, and biomass into valuable syngas, bio-oil, and bio-char.

Whether your goal is research, process development, or small-scale energy recovery, our solutions can help you explore the potential of pyrolysis for landfill diversion and resource creation.

Contact KINTEL today to discuss how our lab equipment can support your waste management and energy recovery projects.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What is the capacity of a rotary furnace? Choose Between Batch or Continuous Processing

- How does pressure affect the pyrolysis process? Control Product Yields of Gas, Liquid, and Char

- What are the main products formed from the pyrolysis process? A Guide to Bio-char, Bio-oil, and Syngas

- What is the rate of fast pyrolysis? Maximizing Bio-Oil Yield with Controlled Thermal Shock

- Does pyrolysis produce carbon monoxide? Harnessing Syngas for Energy and Safety

- What is the carbon content of pyrolysis oil? A Deep Dive into Its Composition and Uses

- What are the advantages of a rotary furnace? Achieve Superior Mixing, Heating, and Process Control

- How does the process of pyrolysis work? Unlock the Power of Chemical Recycling and Energy Recovery