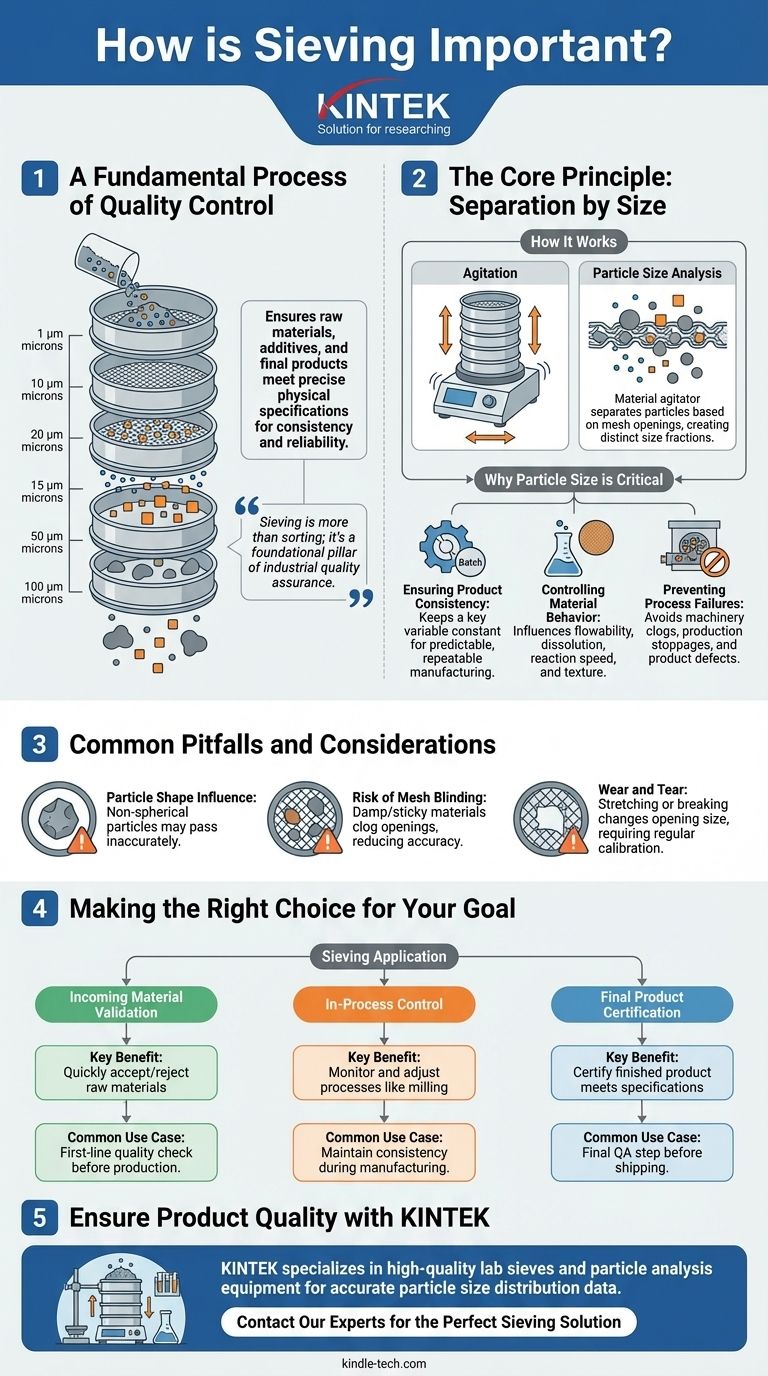

At its core, sieving is a fundamental process of quality control. It is the essential industrial method for separating and analyzing particles based on size, ensuring that raw materials, additives, and final products meet precise physical specifications. Without this crucial step, achieving consistent and reliable product quality is nearly impossible.

Sieving is more than just sorting particles; it is a foundational pillar of industrial quality assurance. Its importance lies in its ability to guarantee that the physical characteristics of a material are correct, which directly dictates the performance, safety, and consistency of the final product.

The Core Principle: Separation by Size

Sieving operates on a simple yet highly effective mechanical principle. By understanding how it works, we can appreciate why it is so indispensable for analyzing materials.

How Sieving Works

The process involves agitating a sample of material over a screen or mesh with uniform openings of a specific size. This is typically achieved through vertical or horizontal motion.

As the material moves, particles smaller than the mesh openings pass through, while larger particles are retained on the surface. This creates a clear physical separation based entirely on particle size.

The Goal of Particle Size Analysis

The primary application of sieving is particle size analysis. By using a stack of sieves with progressively smaller mesh openings, a sample can be separated into various size fractions.

This allows technicians to determine the particle size distribution of a material—a critical quality metric that confirms whether the material conforms to the required specifications for a given application.

Why Particle Size is a Critical Quality Metric

The size of the particles in a substance has a profound impact on its physical and chemical properties. Controlling this variable through sieving is essential for avoiding defects and ensuring performance.

Ensuring Product Consistency

For a product to be reliable, it must be consistent from one batch to the next. Sieving raw materials ensures that a key variable—particle size—is kept constant, leading to predictable and repeatable manufacturing outcomes.

Controlling Material Behavior

Particle size directly influences how a material behaves. It can affect factors like flowability, dissolution rates, reaction speed, and even the texture or appearance of a final product. Accurate sieving guarantees these properties are as intended.

Preventing Process Failures

Using materials with incorrect particle sizes can have severe consequences. Oversized particles can clog machinery and cause production stoppages, while undersized particles can lead to product defects or safety issues. Sieving acts as a critical safeguard against these failures.

Common Pitfalls and Considerations

While powerful, sieving is a physical process with inherent limitations that must be understood to ensure accurate results.

The Influence of Particle Shape

Sieving assumes particles are roughly spherical. Elongated or irregularly shaped particles may pass through a mesh opening end-on or diagonally, leading to a potential misrepresentation of their true size.

Risk of Mesh Blinding

For certain materials, especially those that are damp or sticky, particles can get lodged in the mesh openings. This phenomenon, known as blinding, effectively reduces the open area of the sieve and can lead to inaccurate separation.

Wear and Tear

Over time, the wires of a sieve mesh can stretch, break, or become deformed. This changes the size of the openings and compromises the accuracy of the analysis. Regular inspection and calibration of sieves are therefore essential.

Making the Right Choice for Your Goal

Sieving is not a one-size-fits-all solution; its application depends entirely on your objective within the production lifecycle.

- If your primary focus is incoming material validation: Use sieving as a first-line check to quickly accept or reject raw material shipments, ensuring they meet your base requirements before entering production.

- If your primary focus is in-process control: Employ sieving at intermediate manufacturing stages to monitor processes like milling or granulation and make adjustments to maintain consistency.

- If your primary focus is final product certification: Utilize sieving as a final quality assurance step to certify that your finished product meets its exact particle size specifications before it is shipped to the customer.

Ultimately, sieving is a simple, cost-effective, and powerful tool for guaranteeing the physical integrity of your materials at every stage.

Summary Table:

| Sieving Application | Key Benefit | Common Use Case |

|---|---|---|

| Incoming Material Validation | Quickly accept/reject raw materials | First-line quality check before production |

| In-Process Control | Monitor and adjust processes like milling | Maintain consistency during manufacturing |

| Final Product Certification | Certify finished product meets specifications | Final QA step before shipping to customer |

Ensure your product quality and process consistency with the right sieving equipment.

KINTEK specializes in high-quality lab sieves and particle analysis equipment, designed to deliver accurate and reliable particle size distribution data. Whether you need to validate incoming materials, control in-process parameters, or certify your final product, our solutions help you avoid costly defects and production stoppages.

Contact our experts today to find the perfect sieving solution for your laboratory's specific needs and achieve superior quality assurance.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment