A CVD diamond is designed to last forever. It is a real diamond, possessing the exact same chemical composition and crystal structure as a diamond mined from the Earth. Because of this, it shares the same exceptional durability, scoring a perfect 10 on the Mohs scale of hardness—the highest rating possible for any mineral.

The question of how long a CVD diamond lasts is best answered by a simple fact: it is not a diamond imitation, but a diamond itself. Its longevity is identical to that of a natural diamond because its permanence is determined by its atomic structure, not its origin.

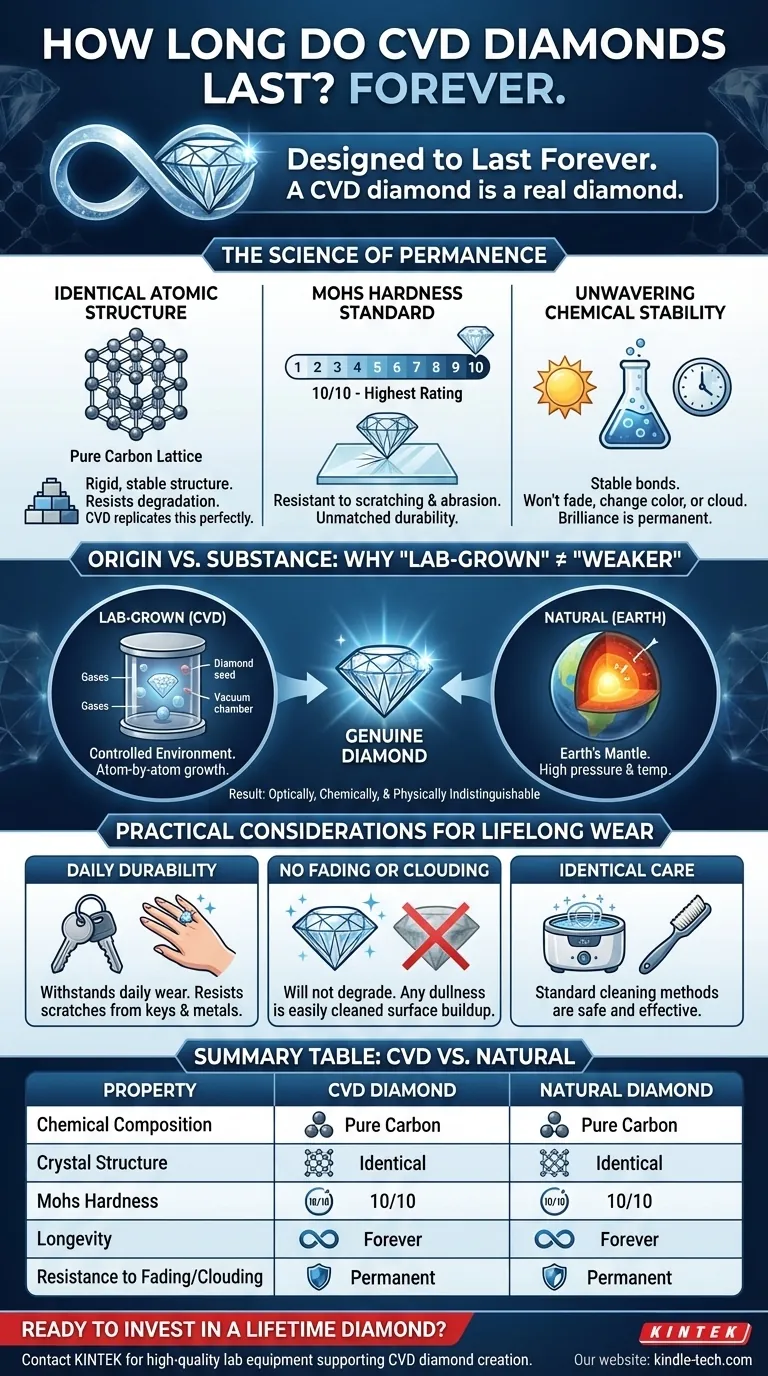

What Makes a Diamond Permanent?

The durability of any diamond, whether created in a lab or formed in the earth, comes from its fundamental physical and chemical properties.

Identical Atomic Structure

A diamond is pure carbon organized in a crystal lattice structure. This rigid, interlocking arrangement of atoms is incredibly strong and stable, making it resistant to degradation over time. CVD diamonds are built atom-by-atom from carbon, perfectly replicating this structure.

The Mohs Hardness Standard

The Mohs scale ranks minerals from 1 (softest) to 10 (hardest). A diamond's rating of 10 means it is exceptionally resistant to scratching and abrasion from any other material except another diamond. This is the primary reason for its unmatched durability in jewelry.

Unwavering Chemical Stability

The carbon bonds in a diamond's crystal lattice are extremely stable. A CVD diamond will not fade, change color, or become cloudy over a lifetime of wear. Its brilliance and fire are permanent properties of its structure, not a temporary coating or treatment.

Origin vs. Substance: Why "Lab-Grown" Doesn't Mean "Weaker"

The primary difference between a CVD diamond and a natural diamond is its point of origin. The process does not create a weaker or inferior substance; it simply recreates the conditions for diamond formation in a controlled environment.

A Replicated Environment

The Chemical Vapor Deposition (CVD) process uses a vacuum chamber to precisely manage temperature and pressure. Carbon-rich gases are introduced, which then break down, allowing carbon atoms to settle and bond onto a diamond seed crystal.

The Result is Diamond

This method builds a genuine diamond layer by layer. The end result is a stone that is optically, chemically, and physically indistinguishable from a high-quality natural diamond. It is not a synthetic like cubic zirconia or moissanite.

Practical Considerations for Lifelong Wear

Understanding the inherent durability of CVD diamonds clarifies how they perform in the real world and addresses common misconceptions.

Durability in Daily Life

Because of its hardness, a CVD diamond easily withstands the rigors of daily wear. It resists scratches from contact with keys, metal surfaces, and other common materials that would damage softer gemstones.

The Myth of Fading or Clouding

A frequent concern is that lab-grown diamonds might degrade over time. This is false. A CVD diamond will not become cloudy or lose its sparkle. Any perceived dullness is simply due to surface buildup of oils and dirt, which can be easily cleaned away, restoring its original brilliance just like with any mined diamond.

Maintenance and Care

The care and cleaning procedures for a CVD diamond are identical to those for a natural one. Standard jewelry cleaners, ultrasonic cleaners, and professional cleaning services are all perfectly safe and effective.

Making the Right Choice for Your Goal

When evaluating a CVD diamond, focus on its properties, not the misconception that "lab-grown" implies a compromise in quality or longevity.

- If your primary focus is permanence and durability: A CVD diamond is an excellent choice, as its lifespan and resilience are scientifically identical to that of a mined diamond.

- If your primary focus is traceability and value: CVD diamonds provide a transparent origin story and often allow you to acquire a larger or higher-quality stone for a comparable budget.

- If your primary focus is authenticity: Rest assured that a CVD diamond is a real diamond in every meaningful way, differing only in its creation story, not its physical substance.

Ultimately, a CVD diamond's permanence is guaranteed by the unchangeable laws of chemistry and physics.

Summary Table:

| Property | CVD Diamond | Natural Diamond |

|---|---|---|

| Chemical Composition | Pure Carbon | Pure Carbon |

| Crystal Structure | Identical | Identical |

| Mohs Hardness | 10/10 | 10/10 |

| Longevity | Forever | Forever |

| Resistance to Fading/Clouding | Permanent | Permanent |

Ready to invest in a diamond that lasts a lifetime?

At KINTEK, we specialize in providing high-quality lab equipment and consumables that enable the creation of exceptional CVD diamonds. Whether you're a jeweler, researcher, or manufacturer, our precision tools ensure you achieve the highest standards of quality and durability.

Contact us today to learn how our solutions can support your diamond production needs and help you deliver lasting value to your customers.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Optical Windows for Lab Applications

People Also Ask

- What is the synthesis of graphene by chemical vapor deposition? Scalable Production of High-Quality Films

- Are semiconductors thin or thick? Discover the Power of Microscopic Thinness in Modern Electronics

- How do you make a sputtering target? The Complete Guide to Manufacturing High-Performance Targets

- What size are sputtering targets? Custom Shapes & Sizes for Your Deposition System

- What are the two methods that can be used to prevent corrosion of a metal? Barrier vs. Sacrificial Protection Explained

- What is the purpose of optical coating? Enhance Your Optical System's Performance

- What is the effect of substrate on thin films? A Critical Factor for Performance and Reliability

- What is medical device coatings? Enhance Safety, Durability & Performance