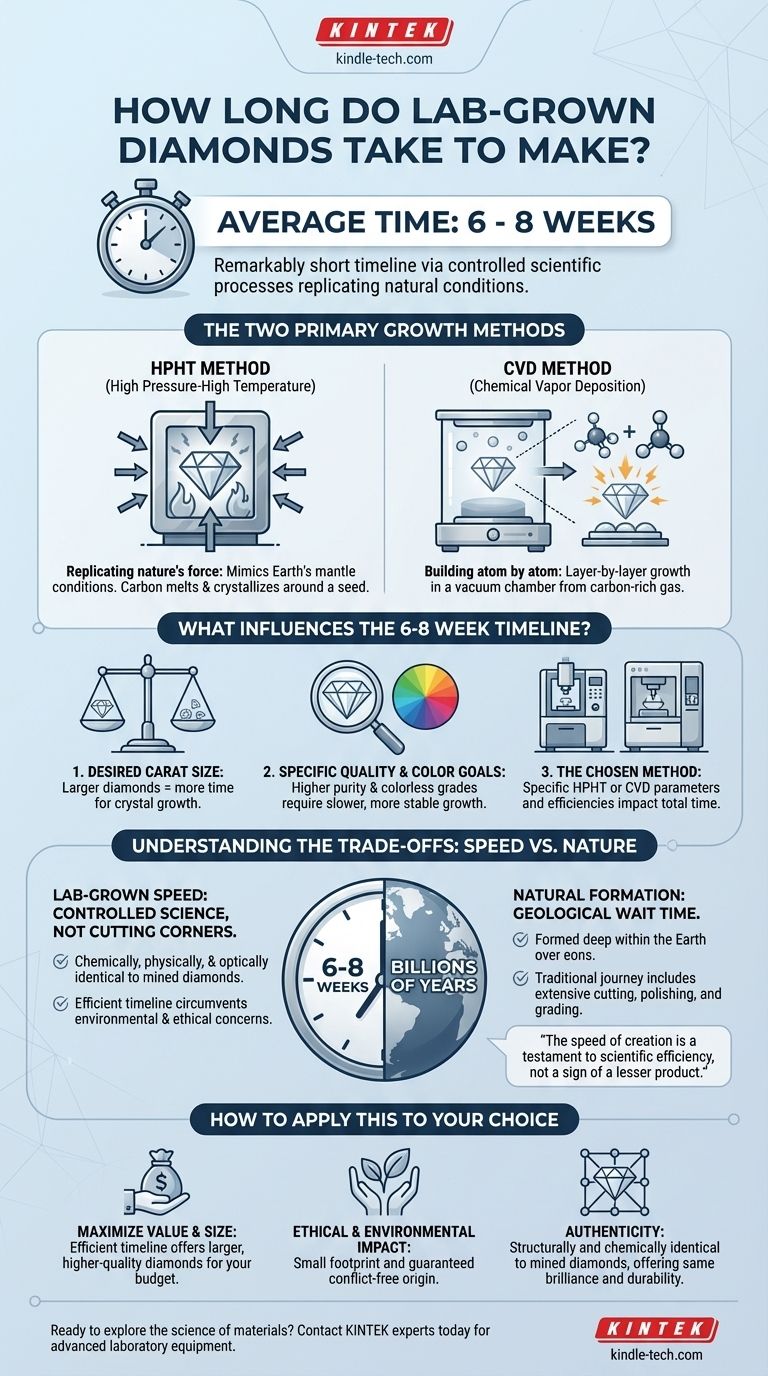

On average, a lab-grown diamond takes between six and eight weeks to create. This remarkably short timeline is the result of highly controlled scientific processes that replicate or accelerate the conditions under which natural diamonds form deep within the Earth. The two dominant commercial methods, High Pressure-High Temperature (HPHT) and Chemical Vapor Deposition (CVD), use advanced technology to crystallize carbon into a genuine diamond.

The speed of lab diamond creation is not a sign of a lesser product; it is a testament to scientific efficiency. Despite the compressed timeline, the resulting stone is chemically, physically, and optically identical to a mined diamond, offering a modern alternative without the geological wait time of billions of years.

The Two Primary Growth Methods

The specific method used to grow a diamond is the biggest factor in its creation process. While several techniques exist, nearly all gem-quality lab diamonds on the market are made using one of two methods.

The HPHT Method: Replicating Nature's Force

The High Pressure-High Temperature (HPHT) method mimics the natural diamond-forming conditions found in the Earth's mantle.

A small diamond "seed" is placed in a chamber with a source of pure carbon. This chamber is then subjected to immense pressures and extremely high temperatures, causing the carbon to melt and crystallize around the seed, forming a new, larger diamond.

The CVD Method: Building Atom by Atom

Chemical Vapor Deposition (CVD) is a fundamentally different approach that builds a diamond layer by layer.

A diamond seed is placed inside a vacuum chamber. The chamber is filled with a carbon-rich gas, like methane, and heated. This energy breaks the gas molecules apart, and the freed carbon atoms are drawn down to the cooler diamond seed, depositing on its surface and growing the crystal one atomic layer at a time.

What Influences the 6-8 Week Timeline?

While six to eight weeks is a reliable average, the exact duration can vary based on several key factors. Think of it less as a fixed recipe and more as a process tailored to a specific outcome.

Desired Carat Size

The most significant factor is the final desired size of the diamond. As you would expect, growing a larger, higher-carat diamond simply requires more time for the carbon crystals to form and accumulate.

Specific Quality and Color Goals

Achieving a higher-quality diamond—one that is colorless and free of inclusions—demands more precise control over the growth environment. Often, a slower, more stable growth rate results in a higher-purity diamond, which can extend the time spent in the chamber.

The Chosen Method

Both HPHT and CVD have their own unique parameters and efficiencies. The specific calibration of temperature, pressure, and gas composition for a given production run will influence the total time needed to achieve the target size and quality.

Understanding the Trade-offs: Speed vs. Nature

The rapid creation time of lab-grown diamonds can lead to misconceptions. It is crucial to understand what this speed implies—and what it does not.

The Myth of "Rushed" Quality

The efficiency of the lab process does not compromise the final product. It is a process of controlled science, not corner-cutting. The resulting diamond has the same crystal structure, chemical composition, and physical properties as a mined diamond. It is a diamond in every sense of the word.

The Timeline You Don't See

The 6-8 week growth period does not account for the immense research and development, cutting-edge equipment, and significant energy required to operate a diamond lab. It also precedes the traditional journey of cutting, polishing, and grading that both lab-grown and mined diamonds undergo.

The True Difference: Origin Story

The primary difference is the origin story and its implications. The controlled, short timeline of a lab diamond circumvents the environmental and ethical concerns often associated with traditional diamond mining. This efficiency is a core part of its value proposition.

How to Apply This to Your Choice

Understanding the creation process empowers you to make a more informed decision that aligns with your priorities.

- If your primary focus is maximizing value and size: The efficient and predictable timeline of lab creation is why you can acquire a larger, higher-quality diamond for your budget compared to a mined equivalent.

- If your primary focus is ethical and environmental impact: The short, contained growth process confirms that your diamond was created with a significantly smaller environmental footprint and a guaranteed conflict-free origin.

- If your primary focus is authenticity: Know that despite being created in weeks rather than eons, the lab diamond is structurally and chemically identical to one from the Earth, offering the same brilliance and durability.

Ultimately, understanding the science behind the timeline allows you to choose a diamond with confidence, based on facts, not fiction.

Summary Table:

| Factor | Impact on Timeline |

|---|---|

| Desired Carat Size | Larger diamonds require more time to grow. |

| Quality & Color Goals | Higher purity and colorlessness can extend the process. |

| Growth Method (HPHT/CVD) | Specific method parameters influence the duration. |

Ready to explore the science of materials? The controlled processes used to create lab-grown diamonds are a testament to modern material science. At KINTEK, we specialize in supplying the advanced laboratory equipment and consumables that power innovation. Whether your lab is focused on materials science, chemistry, or any other field, we provide the reliable tools you need for precise and efficient results. Contact our experts today to discuss how KINTEK can support your laboratory's specific needs and help you achieve your research and production goals.

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- What is MPCVD? Unlock Atom-by-Atom Precision for High-Purity Materials

- How do you get a lab-grown diamond appraised? A Step-by-Step Guide to Accurate Valuation

- What is CVD diamond? The Ultimate Guide to Lab-Grown Diamonds and Their Uses

- What is the demand of CVD diamonds? Driven by Ethics, Purity, and Affordability

- What specific advantages does the MPCVD method have for preparing diamond films? Achieve High-Purity Synthesis

- How are lab-grown diamonds created? Discover the HPHT and CVD Manufacturing Process

- Why is Microwave Plasma Chemical Vapor Deposition (MW-PCVD) preferred for BDD? Achieve Ultra-Pure Diamond Synthesis

- How much cheaper are CVD diamonds? Save 20-30% on a Genuine Diamond