To be precise, most natural diamonds are between 1 billion and 3.3 billion years old. This vast number, however, represents the diamond's total age—the time since it first crystallized deep within the Earth's mantle. The actual period of crystal growth is geologically rapid, but it occurred as part of an ancient, slow-moving process that makes these gems a true relic of the early Earth.

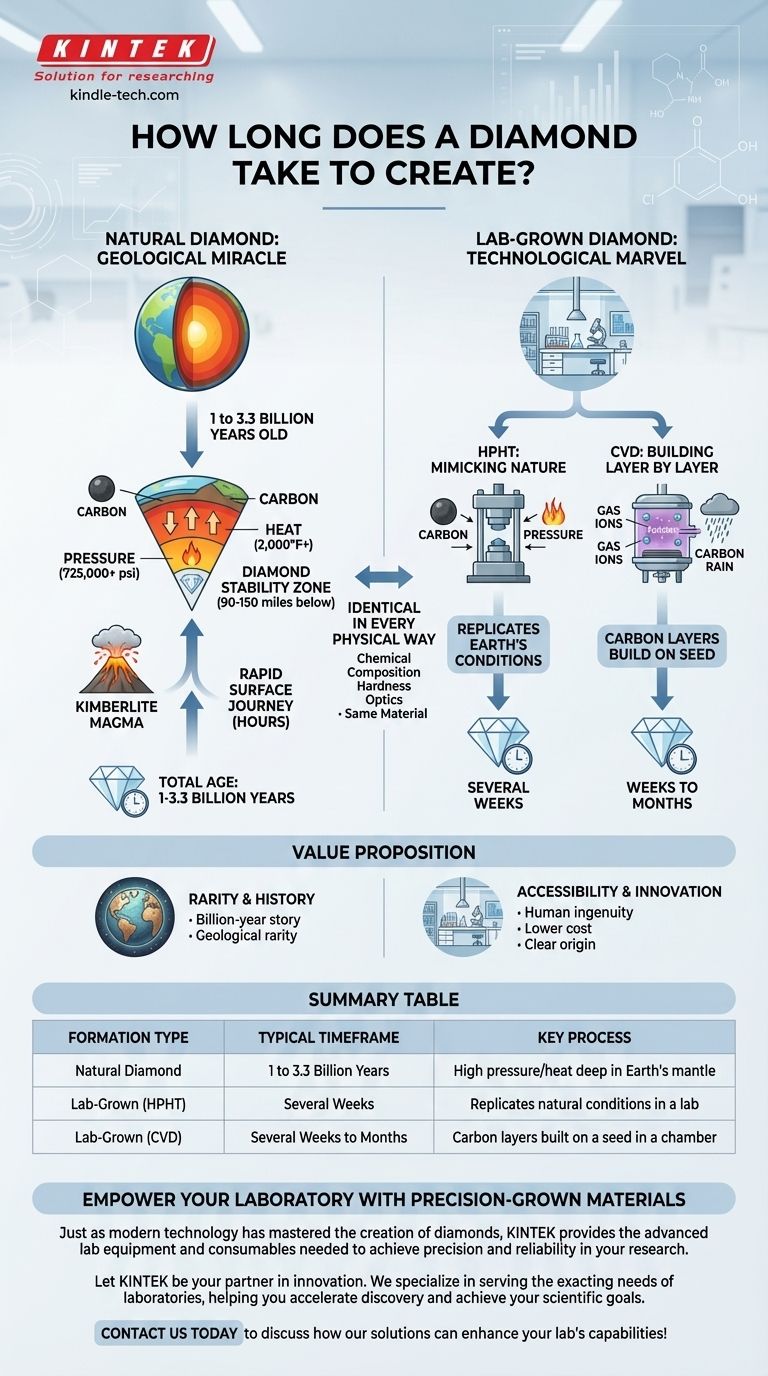

Your question touches on the core difference between a geological miracle and a technological marvel. While natural diamonds are the result of immense timescales, lab-grown diamonds replicate the creation process in a matter of weeks, resulting in a physically identical stone with a vastly different history.

How Natural Diamonds Are Forged in the Earth

The formation of a natural diamond is not a simple event. It requires a precise and violent convergence of ingredients, environment, and a delivery mechanism that is almost impossibly rare.

The Essential Ingredients

To begin, you need carbon. This carbon, trapped deep within the Earth's upper mantle, is subjected to immense pressure (over 725,000 pounds per square inch) and extreme heat (over 2,000°F / 1,093°C).

These conditions are the only way to compel carbon atoms to bond into the incredibly strong, transparent crystalline structure that defines a diamond.

The Diamond Stability Zone

These specific conditions of heat and pressure only exist in certain parts of the upper mantle, about 90 to 150 miles (150 to 250 km) below the surface.

This region is known as the "diamond stability zone." Outside of this zone, carbon will either remain as graphite or vaporize.

The Journey to the Surface

After forming, these diamonds can remain in the mantle for millions or billions of years. Their journey to the surface is a violent and rapid event.

They are carried upward by deep-source volcanic eruptions. The magma, known as kimberlite, travels at incredible speeds, carrying the diamonds to the surface in a matter of hours. This speed is crucial, as a slower journey would cause the diamonds to transform back into graphite.

The Rise of Lab-Grown Diamonds

Technology now allows us to replicate the diamond creation process in a controlled environment. The outcome is a stone that is chemically, physically, and optically identical to a natural diamond.

HPHT: Mimicking Nature

The High-Pressure/High-Temperature (HPHT) method most closely mimics the natural process. A small diamond "seed" is placed with pure carbon and subjected to immense pressure and heat.

This process essentially recreates the conditions of the Earth's mantle, allowing the carbon to crystallize and form a new diamond. This typically takes several weeks.

CVD: Building Layer by Layer

The Chemical Vapor Deposition (CVD) method works differently. A diamond seed is placed in a sealed chamber filled with carbon-rich gas and heated.

The gasses are ionized into plasma, causing pure carbon to "rain" down and build upon the seed in layers. This process can take from several weeks to a few months, depending on the desired size and quality.

Does Formation Time Affect the Final Stone?

The fundamental difference between a natural and lab-grown diamond is its origin story and the time it took to form. This distinction has no bearing on the stone's physical properties but is central to its value.

Identical in Every Physical Way

A gemologist cannot tell the difference between a natural and a lab-grown diamond with the naked eye. Both have the same chemical composition, hardness, and light-reflecting properties.

They are, for all practical purposes, the same material. Specialized equipment is required to identify the subtle differences in growth patterns and trace elements that reveal their origin.

Rarity vs. Technology

The value proposition is therefore one of scarcity versus innovation. A natural diamond's value is tied to its geological rarity and the billion-year story it represents.

A lab-grown diamond's value comes from its accessibility and the human ingenuity required to create it. It offers an identical product without the high cost and environmental impact associated with mining.

Making the Right Choice for Your Goal

Your reason for asking about a diamond's creation time likely informs what you value in the stone itself.

- If your primary focus is geological rarity and history: A natural diamond is your only choice, as each one is a unique, irreplaceable artifact of the ancient Earth.

- If your primary focus is maximizing size and quality for your budget: A lab-grown diamond provides a physically identical and often more flawless option for a significantly lower cost.

- If your primary focus is environmental and ethical transparency: Lab-grown diamonds offer a clear chain of custody and avoid the complexities associated with traditional diamond mining.

Understanding a diamond's journey—whether over billions of years or a few weeks—empowers you to choose the stone that best reflects your own values.

Summary Table:

| Formation Type | Typical Timeframe | Key Process |

|---|---|---|

| Natural Diamond | 1 to 3.3 Billion Years | High pressure/heat deep in Earth's mantle |

| Lab-Grown (HPHT) | Several Weeks | Replicates natural conditions in a lab |

| Lab-Grown (CVD) | Several Weeks to Months | Carbon layers built on a seed in a chamber |

Empower Your Laboratory with Precision-Grown Materials

Just as modern technology has mastered the creation of diamonds, KINTEK provides the advanced lab equipment and consumables needed to achieve precision and reliability in your research. Whether you are synthesizing new materials or conducting high-temperature experiments, our products are engineered to deliver consistent, high-quality results.

Let KINTEK be your partner in innovation. We specialize in serving the exacting needs of laboratories, helping you accelerate discovery and achieve your scientific goals.

Contact us today to discuss how our solutions can enhance your lab's capabilities!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- Why do you need to follow the safety procedure in using hydraulic tools? Prevent Catastrophic Failure and Injury

- How is the pressure and temperature process used to make a synthetic diamond? Replicate Earth's Diamond Formation in a Lab

- How does a vacuum furnace environment influence sintered Ruthenium powder? Achieve High Purity and Theoretical Density