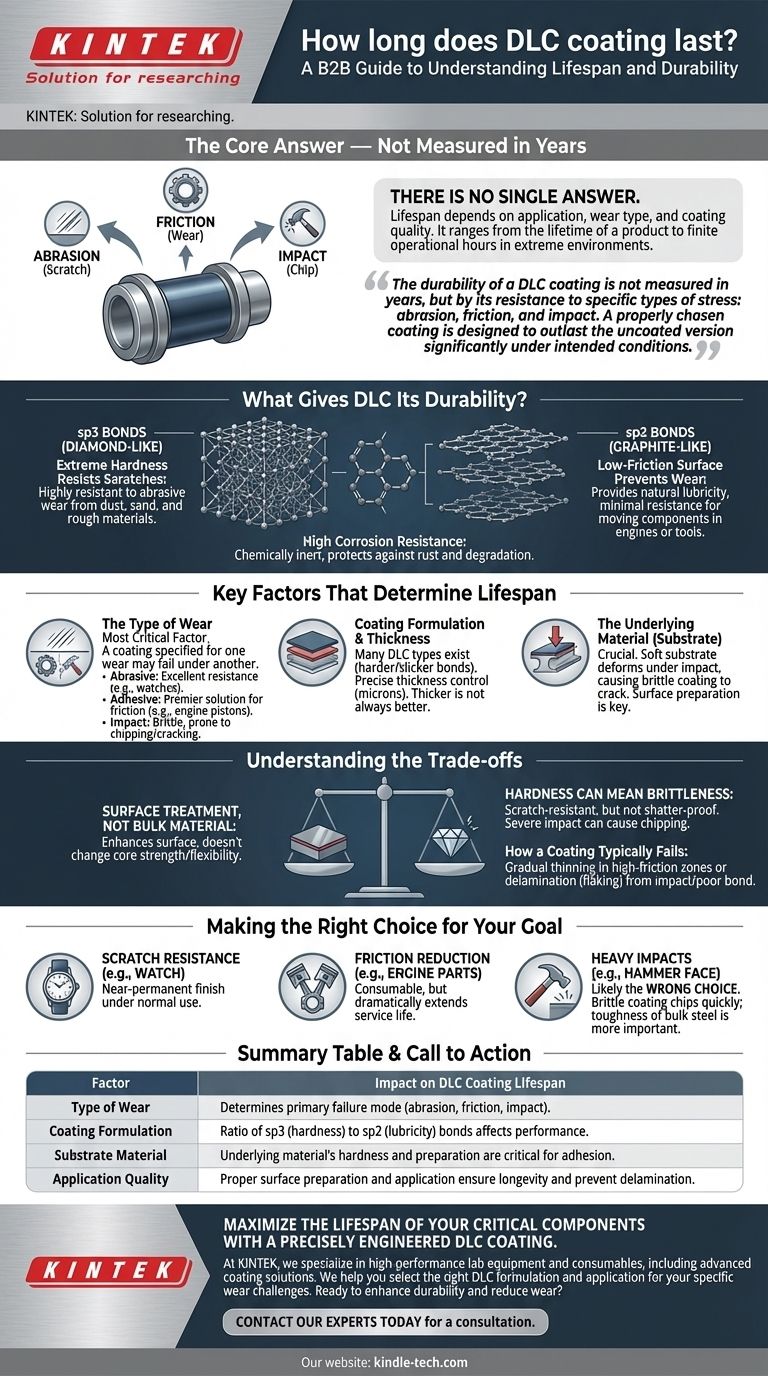

There is no single answer to how long a Diamond-Like Carbon (DLC) coating lasts. Its lifespan is determined entirely by the specific application, the type of wear it endures, and the quality of the coating itself. It can range from the effective lifetime of a consumer product like a watch to a finite number of operational hours in extreme industrial environments.

The durability of a DLC coating is not measured in years, but by its resistance to specific types of stress: abrasion, friction, and impact. A properly chosen and applied coating is designed to outlast the uncoated version of the part, often by a significant margin, under its intended working conditions.

What Gives DLC Its Durability?

The exceptional lifespan of DLC in the right applications comes from its unique atomic structure, which combines the properties of both diamond and graphite.

A Hybrid Atomic Structure

DLC is not a single material but a class of coatings composed of carbon atoms. It contains a mixture of sp3 bonds, the same type found in diamond, and sp2 bonds, the same type found in graphite. This combination is the source of its most valuable traits.

Extreme Hardness Resists Scratches

The diamond-like sp3 bonds give the coating its signature high hardness. This makes the surface highly resistant to abrasive wear, which is damage caused by scratching from hard particles like dust, sand, or other rough materials.

Low-Friction Surface Prevents Wear

The graphite-like sp2 bonds provide a natural lubricity, or slickness. This results in a very low coefficient of friction, meaning parts can slide against each other with minimal resistance and wear. This is critical for the longevity of moving components in engines or tools.

High Corrosion Resistance

DLC coatings are chemically inert, meaning they do not react easily with their environment. This provides excellent protection against rust and degradation from exposure to moisture and various chemicals.

Key Factors That Determine Lifespan

Instead of asking "how many years," the correct question is, "what forces will the coating have to withstand?" The answer determines its longevity.

The Type of Wear

This is the most critical factor. A coating specified for one type of wear may fail quickly when subjected to another.

- Abrasive Wear (Scratches): This is contact with hard, sharp particles. DLC is exceptionally good at resisting this, which is why it's popular on high-end watches.

- Adhesive Wear (Friction): This occurs when two surfaces slide against each other under pressure. DLC's low friction makes it a premier solution for this, extending the life of engine pistons, bearings, and cutting tools.

- Impact: This involves sudden, sharp forces. While very hard, DLC is also a very thin, brittle layer. A significant impact can cause it to chip or crack.

The Coating's Formulation and Thickness

There are many different types of DLC, some with more diamond-like (harder) bonds and others with more graphite-like (slicker) bonds. The thickness, typically just a few microns (millionths of a meter), is also precisely controlled for the application. A thicker coating is not always better, as it can increase internal stress.

The Underlying Material (Substrate)

The material under the coating is just as important as the coating itself. A hard DLC coating on a soft metal base can fail if the base deforms under impact, causing the rigid coating to crack. The surface preparation before coating is also critical for ensuring a strong bond.

Understanding the Trade-offs

To make an informed decision, you must understand the limitations of DLC. It is a specialized solution, not a universal armor.

It Is a Surface Treatment, Not Bulk Material

A DLC coating is an extremely thin layer. It enhances the surface properties of a component but does not change the core characteristics—like strength or flexibility—of the material underneath.

Hardness Can Mean Brittleness

The primary trade-off for extreme hardness is a degree of brittleness. DLC is scratch-resistant, but it is not shatter-proof. A severe, direct impact can chip the coating, whereas a softer material might only dent.

How a Coating Typically Fails

Failure doesn't always mean the coating vanishes. It can manifest as a gradual thinning in a high-friction zone or as "delamination" (flaking or chipping) if the bond to the substrate fails, usually due to a powerful impact or improper application.

Making the Right Choice for Your Goal

Assess the durability of DLC based on its intended purpose.

- If your primary focus is scratch resistance for an everyday item (like a watch or knife): A quality DLC coating should last for many years under normal use and can be considered a near-permanent finish, barring severe impacts.

- If your primary focus is reducing friction in mechanical parts (engine components, industrial tools): The coating is a consumable, but one that is designed to dramatically extend the service life of the part far beyond its uncoated equivalent.

- If your primary focus is resisting heavy impacts (like on a hammer face): DLC is likely the wrong choice. The toughness of the bulk steel is more important, as the brittle coating would likely chip away quickly.

Ultimately, understanding the specific forces your component will face is the key to predicting the true lifespan of its DLC coating.

Summary Table:

| Factor | Impact on DLC Coating Lifespan |

|---|---|

| Type of Wear | Determines primary failure mode (abrasion, friction, impact). |

| Coating Formulation | Ratio of sp3 (hardness) to sp2 (lubricity) bonds affects performance. |

| Substrate Material | The underlying material's hardness and preparation are critical for adhesion. |

| Application Quality | Proper surface preparation and application ensure longevity and prevent delamination. |

Maximize the lifespan of your critical components with a precisely engineered DLC coating.

At KINTEK, we specialize in high-performance lab equipment and consumables, including advanced coating solutions. Our expertise ensures your parts are protected against the specific wear challenges they face—whether it's abrasive, adhesive, or corrosive. We help you select the right DLC formulation and application process to significantly extend the service life of your tools, engine components, and industrial parts.

Ready to enhance durability and reduce wear? Contact our experts today for a consultation tailored to your laboratory or industrial needs.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer