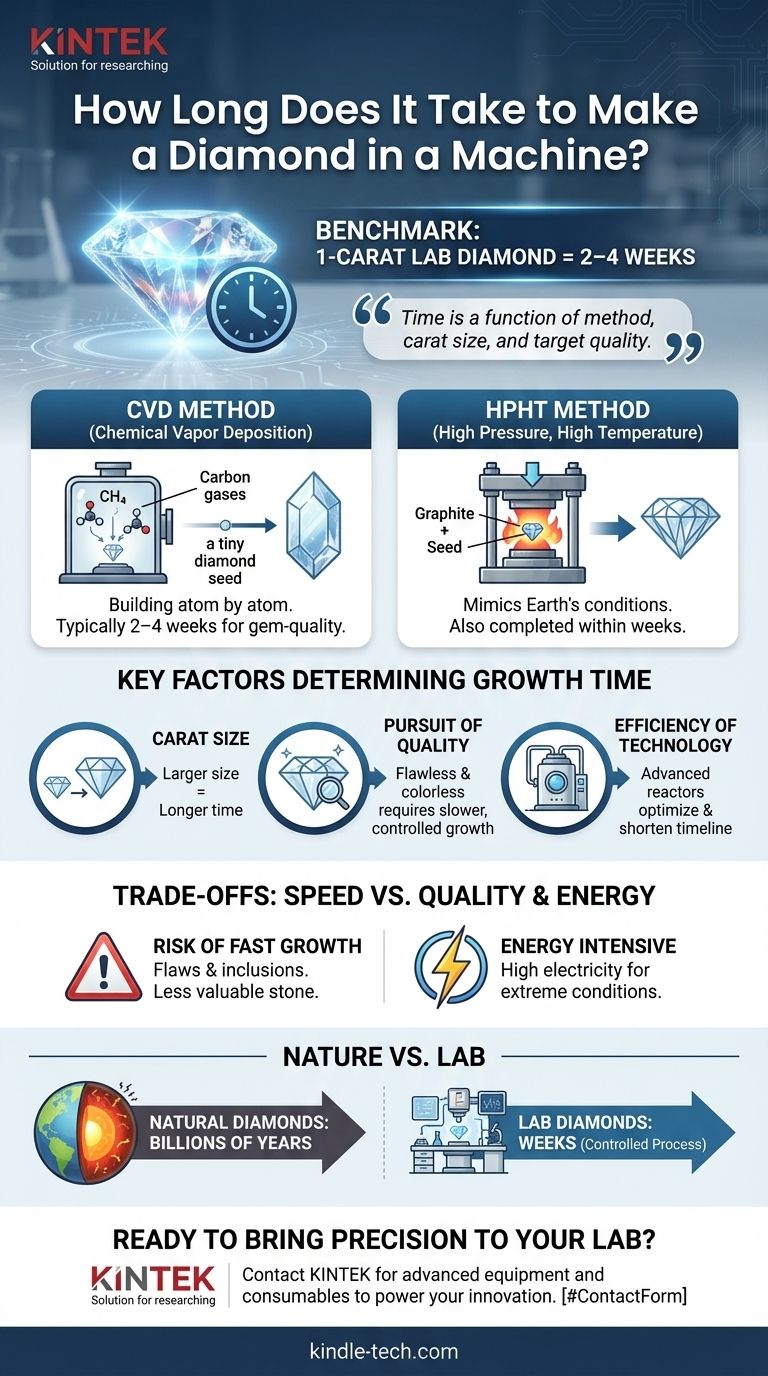

In a laboratory, a high-quality, 1-carat diamond can be grown in as little as two to four weeks. This process, a marvel of material science, relies on sophisticated technology that replicates the diamond-forming conditions of the Earth's mantle, but on a vastly accelerated timeline.

The time required to grow a diamond is not fixed; it is a direct function of the chosen growth method, the desired carat size, and the targeted level of quality. Understanding this relationship is key to appreciating the technology behind lab-created diamonds.

The Two Primary Methods of Diamond Creation

At the heart of lab-grown diamonds are two distinct technological approaches. Each method grows a chemically and physically identical diamond, but the process and timeline differ.

The CVD Method (Chemical Vapor Deposition)

Chemical Vapor Deposition, or CVD, is akin to building a crystal atom by atom. The process begins with a tiny diamond "seed" placed inside a sealed vacuum chamber.

This chamber is filled with carbon-rich gases (like methane) and heated to extreme temperatures. The gases break down, and carbon atoms "rain" down, depositing onto the seed and growing the diamond in successive layers. This method typically takes two to four weeks for a gem-quality stone.

The HPHT Method (High Pressure, High Temperature)

High Pressure, High Temperature (HPHT) is the original method and more closely mimics the natural geologic process. It starts with a diamond seed and pure, solid carbon (like graphite).

This material is placed in a large mechanical press that applies immense pressure and intense heat—simulating the conditions deep within the Earth. The solid carbon melts and re-forms as a diamond crystal around the seed. While timelines vary, this process is also completed within a matter of weeks.

Key Factors That Determine Growth Time

The "two to four weeks" figure is a benchmark, not a universal constant. Several critical factors can shorten or lengthen the duration of the growth cycle.

The Role of Carat Size

The most significant factor is carat size. A larger diamond simply requires more material and more time for the crystalline structure to form, whether it's through the layering of CVD or the crystallization of HPHT. Growing a 3-carat diamond will take considerably longer than a 1-carat stone.

The Pursuit of Quality and Clarity

Growing a diamond is not just about speed; it's about precision. Creating a flawless, colorless diamond requires slower, more stable, and more controlled conditions to prevent inclusions or structural defects from forming. Rushing the process can compromise the final quality.

The Efficiency of the Technology

The specific equipment used plays a crucial role. Top producers with the latest, most efficient reactors can optimize temperature, pressure, and gas composition to grow high-quality diamonds more quickly than those using older technology. Continuous innovation in this field is constantly refining the process.

Understanding the Trade-offs: Speed vs. Quality

The ability to create a diamond in weeks is remarkable, but it involves a delicate balance of competing variables. The process is governed by physics and chemistry, where every choice has a consequence.

The Risk of Growing Too Fast

Attempting to accelerate growth beyond what the process can stably handle is the primary cause of flaws and inclusions. Rapid, unstable growth can trap non-diamond carbon or create fractures in the crystal lattice, resulting in a lower-clarity and less valuable stone.

The Energy Cost of Creation

Both CVD and HPHT methods are extremely energy-intensive. Maintaining the incredible pressures and temperatures required to form a diamond consumes a significant amount of electricity. This is a fundamental trade-off of the technology—speed and control are achieved at a high energy cost.

The Contrast with Natural Formation

The most profound context for lab growth time is its comparison to nature. Natural diamonds form over billions of years under chaotic conditions deep within the Earth's mantle. Laboratory methods are about controlling this process to produce a specific result in a tiny fraction of the time.

How to Interpret This Information

Understanding the growth timeline helps you appreciate the science behind the stone. Your interpretation of this fact depends on your ultimate goal.

- If your primary focus is the technology: Recognize that lab diamond creation is a precise manufacturing process where time is a key variable managed to optimize for both size and quality.

- If your primary focus is purchasing a diamond: The specific growth time is less important than the final, certified result—the 4Cs (cut, color, clarity, and carat) are what determine a diamond's quality and value.

- If your primary focus is the environmental impact: The critical factor is not the number of weeks, but the high energy consumption of the process and whether that energy comes from a renewable or fossil-fuel source.

Ultimately, knowing how long it takes to grow a diamond empowers you to see it not as an imitation, but as a product of human ingenuity and scientific mastery.

Summary Table:

| Factor | Impact on Growth Time |

|---|---|

| Method | CVD: 2-4 weeks. HPHT: Varies, but typically weeks. |

| Carat Size | Larger carat = longer growth time. |

| Target Quality | Higher clarity/color grades require slower, more controlled growth. |

| Technology | Advanced, efficient reactors can optimize and shorten the timeline. |

Ready to bring precision and efficiency to your laboratory processes? At KINTEK, we specialize in the advanced equipment and consumables that power innovation. Whether your research involves material science, chemistry, or any lab-based application, our solutions are designed to enhance your results and streamline your workflow. Contact us today via our [#ContactForm] to discuss how KINTEK can support your specific laboratory needs and help you achieve your scientific goals.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Domes for Industrial and Scientific Applications

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- Are CVD diamonds fake? Discover the Truth About Lab-Grown Diamonds

- How does chemical vapor deposition work for diamonds? Grow Lab-Created Diamonds Layer by Layer

- What are synthetic diamonds used for in industry? Powering High-Tech Tools and Electronics

- What are the technical characteristics of a Rotational Ellipsoidal Cavity (REC) reactor? Optimize Diamond Growth

- Is there certification for lab-grown diamonds? Get Independent Verification for Your Purchase

- Are artificial diamonds as strong as natural diamonds? Discover the Truth About Lab-Grown Diamond Durability

- Can I buy lab diamonds? Your Guide to Modern, Ethical, and Affordable Diamonds

- What is MPCVD? Unlock Atom-by-Atom Precision for High-Purity Materials