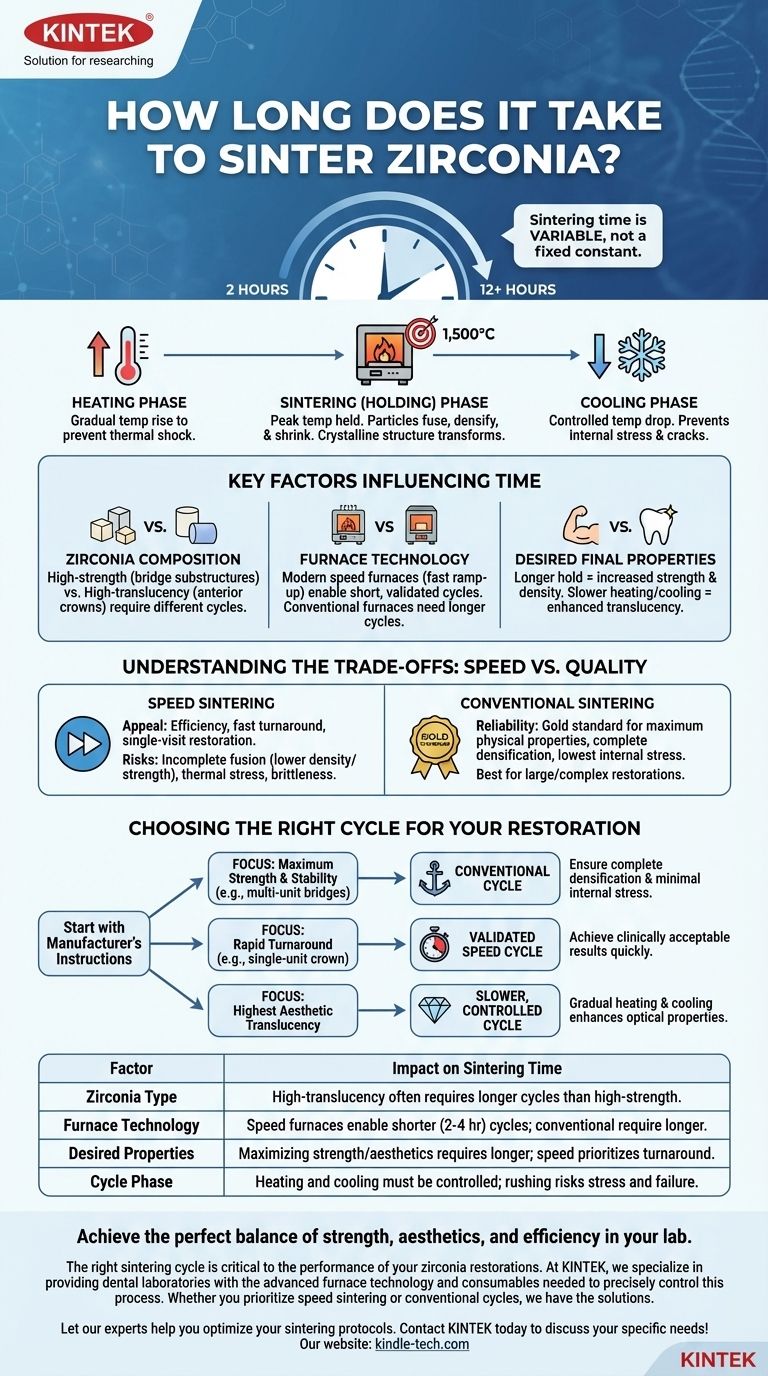

The sintering time for zirconia is not a single number but a variable process that can range from as little as two hours to over twelve. The exact duration is a carefully calculated protocol dependent on the specific type of zirconia, the furnace technology being used, and the desired balance between mechanical strength and aesthetic translucency. For this reason, adhering to the manufacturer's specific instructions is paramount.

The duration of a zirconia sintering cycle is a deliberate choice, not a fixed constant. It represents a critical trade-off between the speed of production and the goal of achieving the material's maximum potential for strength, density, and aesthetics.

Deconstructing the Sintering Cycle

Every sintering program, regardless of its total duration, is composed of three distinct and critical phases. Understanding what happens in each phase explains why the process cannot be arbitrarily rushed.

The Heating Phase

This initial phase involves gradually raising the temperature of the zirconia restoration. A slow, controlled ramp-up is essential to prevent thermal shock, which could introduce micro-fractures before the material even reaches its peak temperature.

The Sintering (Holding) Phase

Once the furnace reaches its target temperature—typically around 1,500°C—it holds this temperature for a prescribed period. During this phase, the individual zirconia particles fuse together, eliminating porosity and causing the material to densify and shrink significantly. This is also where the crystalline structure transforms, which is critical for achieving its final strength.

The Cooling Phase

Just as important as the heating phase, the cooling phase must also be carefully controlled. Lowering the temperature too quickly can create internal stresses within the material, compromising the structural integrity and long-term stability of the final restoration.

Key Factors Influencing Sintering Time

The significant variation in cycle times comes down to a few key variables. The "right" duration is a function of the material, the equipment, and the intended clinical outcome.

Zirconia Composition

Different zirconia formulations are engineered for different purposes. High-strength zirconia used for bridge substructures may have a different optimal cycle than a high-translucency zirconia designed for monolithic anterior crowns, which often requires a slower cycle to maximize its aesthetic properties.

Furnace Technology

Modern "speed" furnaces are designed with advanced heating elements and insulation that allow for much faster temperature ramp-up and cool-down rates. These enable validated short cycles without damaging the material. Conventional furnaces require longer, more gradual cycles to achieve the same result safely.

Desired Final Properties

The ultimate goal dictates the process. A longer hold at the peak temperature can increase densification and flexural strength, while a slower heating and cooling rate can enhance translucency. The manufacturer's recommended cycles are designed to achieve a specific, tested balance of these properties.

Understanding the Trade-offs: Speed vs. Quality

The decision to use a short or long sintering cycle is a conscious choice with clear implications. While tempting, speed is not always the best path.

The Appeal of Speed Sintering

The primary benefit of a rapid cycle is efficiency. For dental labs and clinics, a faster turnaround means a single-visit restoration is possible, increasing productivity and patient satisfaction.

The Risks of Rushing the Process

Using an unvalidated or overly aggressive speed cycle can be detrimental. It risks incomplete particle fusion, leading to lower density and strength. More importantly, it can lock in thermal stress, making the final restoration more brittle and prone to premature failure.

The Reliability of Conventional Sintering

Longer, conventional cycles remain the gold standard for maximizing the physical properties of zirconia. They ensure the most complete densification and the lowest possible internal stress, making them the safest choice for large, complex, or high-stress restorations like multi-unit bridges.

Choosing the Right Cycle for Your Restoration

Your decision should always start with the manufacturer's instructions for the specific zirconia you are using. Within those guidelines, tailor your choice to the clinical demand.

- If your primary focus is maximum strength and stability (e.g., for multi-unit bridges): Default to the manufacturer's conventional, longer sintering cycle to ensure complete densification and minimal internal stress.

- If your primary focus is rapid turnaround for a single-unit crown: Use a validated speed-sintering cycle specifically designed for your material and furnace to achieve clinically acceptable results quickly.

- If your primary focus is achieving the highest aesthetic translucency: Opt for a slower, more controlled cycle, as this gradual heating and cooling often enhances the final optical properties of the zirconia.

Ultimately, understanding the principles behind the sintering time transforms it from a mere number into a powerful tool for controlling the final outcome.

Summary Table:

| Factor | Impact on Sintering Time |

|---|---|

| Zirconia Type | High-translucency zirconia often requires longer cycles than high-strength types. |

| Furnace Technology | Speed furnaces enable shorter cycles (2-4 hours); conventional furnaces require longer cycles. |

| Desired Properties | Maximizing strength/aesthetics requires longer cycles; speed sintering prioritizes turnaround. |

| Cycle Phase | Heating and cooling must be controlled; rushing risks stress and failure. |

Achieve the perfect balance of strength, aesthetics, and efficiency in your lab.

The right sintering cycle is critical to the performance of your zirconia restorations. At KINTEK, we specialize in providing dental laboratories with the advanced furnace technology and consumables needed to precisely control this process. Whether you prioritize speed sintering for single-visit dentistry or conventional cycles for maximum bridge strength, we have the solutions to meet your clinical demands.

Let our experts help you optimize your sintering protocols for consistent, high-quality results. Contact KINTEK today to discuss your lab's specific equipment and material needs!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations