In simple terms, biomass energy often costs more per unit of electricity than new utility-scale solar and wind, but its price can be competitive with fossil fuels like natural gas. However, a single cost figure is misleading because the price of biomass is highly variable, depending heavily on the specific fuel source (feedstock), the technology used, and the scale of the project.

The true value of biomass isn't just about its cost per kilowatt-hour; it's about its ability to provide reliable, on-demand power from a renewable source, a crucial function that intermittent sources like solar and wind cannot fulfill on their own.

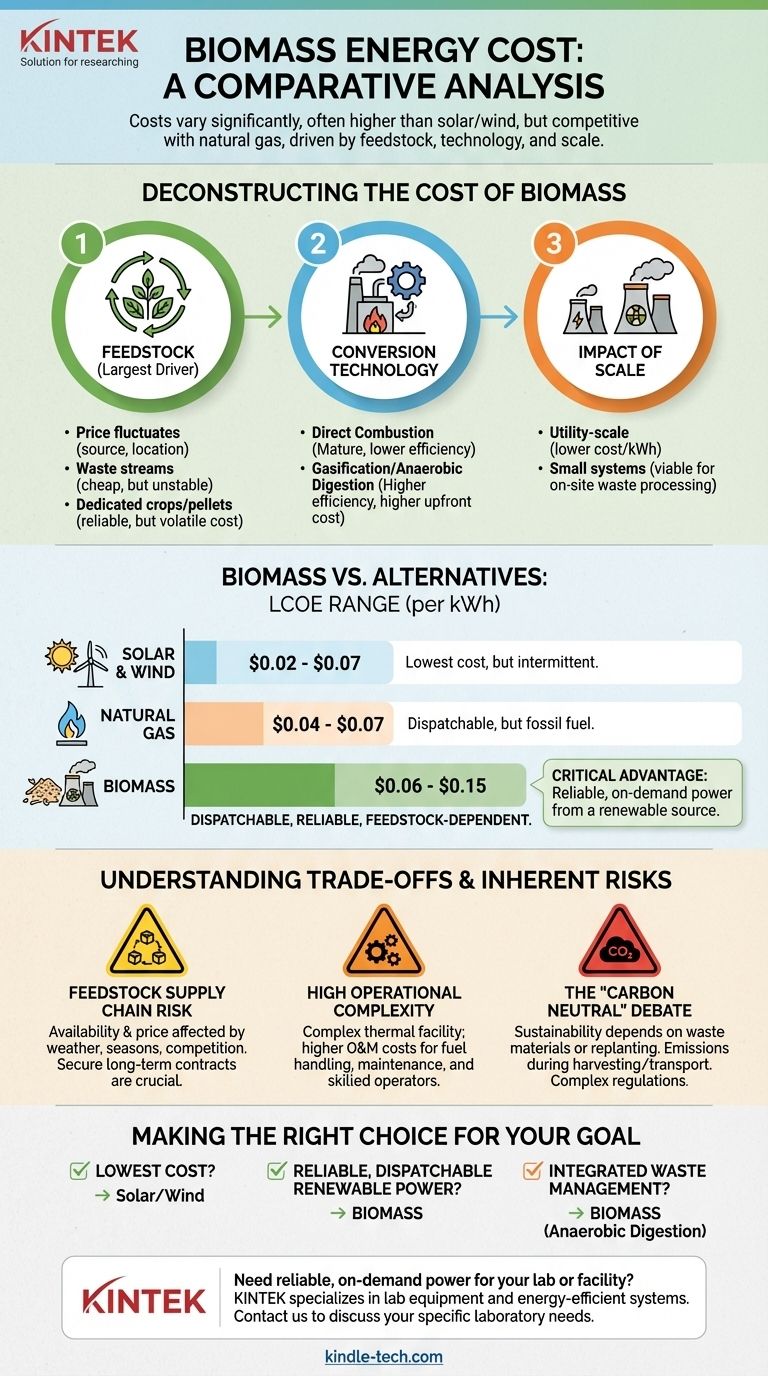

Deconstructing the Cost of Biomass

The price of energy from biomass is not a fixed number. It is a result of a complex supply chain and significant capital investment, with three factors having the most influence.

The Critical Role of Feedstock

The single largest driver of cost is the feedstock—the organic material itself. The price fluctuates based on what you use and where you get it.

Agricultural residues, forestry byproducts, or municipal solid waste can be very cheap or even have a negative cost if you are being paid to haul them away.

However, relying on these "waste" streams can create an unstable supply. Dedicated energy crops or processed fuels like wood pellets offer a more reliable supply but come at a much higher and more volatile cost.

Conversion Technology Matters

The technology used to convert biomass into energy significantly impacts both upfront capital costs and long-term operational efficiency.

Direct combustion, burning the material to create steam that turns a turbine, is the most mature and common technology. It is well-understood but may not be the most efficient.

Newer technologies like gasification or anaerobic digestion can be more efficient and produce valuable byproducts, but they often require higher initial investment and more complex operations.

The Impact of Scale

Like most power generation, biomass plants benefit from economies of scale.

Large, utility-scale facilities can produce electricity at a much lower cost per kilowatt-hour (kWh) than small, localized systems. However, small plants can be economically viable if they are solving a specific problem, such as processing a factory's on-site waste to generate its power.

Biomass vs. The Alternatives: A Comparative Analysis

To truly understand the cost, we must compare biomass to other energy sources using a standard metric: the Levelized Cost of Energy (LCOE), which represents the average revenue per unit of electricity generated that would be required to recover the costs of building and operating a generating plant over its lifetime.

Comparison with Renewables (Solar & Wind)

On a pure LCOE basis, new utility-scale solar and wind are now consistently cheaper than most new biomass plants. Typical LCOE ranges can be $0.02 - $0.07 per kWh for wind and solar.

The critical advantage of biomass is its dispatchability. It can be turned on and off as needed, providing stable baseload power when the sun isn't shining or the wind isn't blowing. This reliability has immense value for grid stability.

Comparison with Fossil Fuels (Natural Gas, Coal)

Biomass can be cost-competitive with fossil fuels, especially natural gas, which typically has an LCOE of $0.04 - $0.07 per kWh.

While the operational fuel costs can be similar, biomass plants often have higher upfront capital costs. Furthermore, the biomass fuel supply is far less predictable and commoditized than the global natural gas market, introducing significant price risk.

The LCOE Range for Biomass

The LCOE for biomass has a very wide range, typically falling between $0.06 and $0.15 per kWh. This wide variation is a direct result of the feedstock, technology, and scale factors discussed earlier.

Understanding the Trade-offs and Inherent Risks

Choosing biomass involves accepting a unique set of challenges that are not purely financial but have significant economic consequences.

Feedstock Supply Chain Risk

This is the most significant challenge. The availability and price of biomass feedstock can be affected by weather, seasonal cycles, and competition from other industries (e.g., construction or paper manufacturing).

Securing a long-term, stable, and affordable feedstock contract is the most critical step for any biomass project's financial success.

High Operational Complexity

Unlike a solar farm, a biomass power plant is a complex thermal facility. It requires constant fuel handling, ash management, boiler maintenance, and skilled on-site operators.

These factors lead to higher operational and maintenance (O&M) costs compared to the relatively simple O&M of solar and wind installations.

The "Carbon Neutral" Debate

While often classified as renewable, the carbon neutrality of biomass is complex. Emissions are produced during harvesting, transportation, and combustion.

The sustainability of a project depends entirely on using waste materials or ensuring that new plants are grown to recapture the carbon released. Navigating these environmental regulations and perceptions can add indirect costs.

Making the Right Choice for Your Goal

The decision to use biomass should be driven by your strategic energy goals, not just a simple comparison of cost per kWh.

- If your primary focus is the absolute lowest cost of electricity: New utility-scale solar or wind power in favorable locations will almost always be the cheaper option.

- If your primary focus is reliable, dispatchable renewable power: Biomass is a powerful contender, providing the baseload or on-demand generation needed to support an energy grid heavy with intermittent renewables.

- If your primary focus is integrated waste management: Biomass technologies, especially anaerobic digestion, offer an excellent solution for converting agricultural, industrial, or municipal waste streams into valuable energy.

Ultimately, understanding biomass requires viewing it not just as a power source, but as a complex system whose cost and value are defined by your specific circumstances.

Summary Table:

| Energy Source | Typical LCOE Range (per kWh) | Key Characteristic |

|---|---|---|

| Biomass | $0.06 - $0.15 | Dispatchable, reliable, feedstock-dependent |

| Solar & Wind | $0.02 - $0.07 | Lowest cost, but intermittent |

| Natural Gas | $0.04 - $0.07 | Dispatchable, but fossil fuel |

Need reliable, on-demand power for your lab or facility? KINTEK specializes in lab equipment and consumables, including energy-efficient systems that support sustainable operations. Whether you're evaluating biomass applications or optimizing your energy use, our expertise can help you achieve greater efficiency and cost savings. Contact us today to discuss your specific laboratory needs and how we can support your goals with the right equipment solutions.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Wall Mounted Water Distillation Unit

- Carbon Graphite Plate Manufactured by Isostatic Pressing Method

People Also Ask

- What is sintering of clay materials? The Science of Turning Clay into Durable Ceramics

- What is a rotavap used for? Achieve Fast, Gentle Solvent Evaporation for Your Lab

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- How much does a biochar production facility cost? From $100k to $10M+ for Your Project

- What are the disadvantages of hardening steel? Understanding the Trade-offs in Strength and Toughness

- What are the advantages of microwave pyrolysis? Faster, More Efficient Waste Conversion

- How much more efficient are electric arc furnaces? Achieve 90% Energy Savings in Steel Production

- Is XRF destructive? Balancing Sample Integrity with Analytical Accuracy