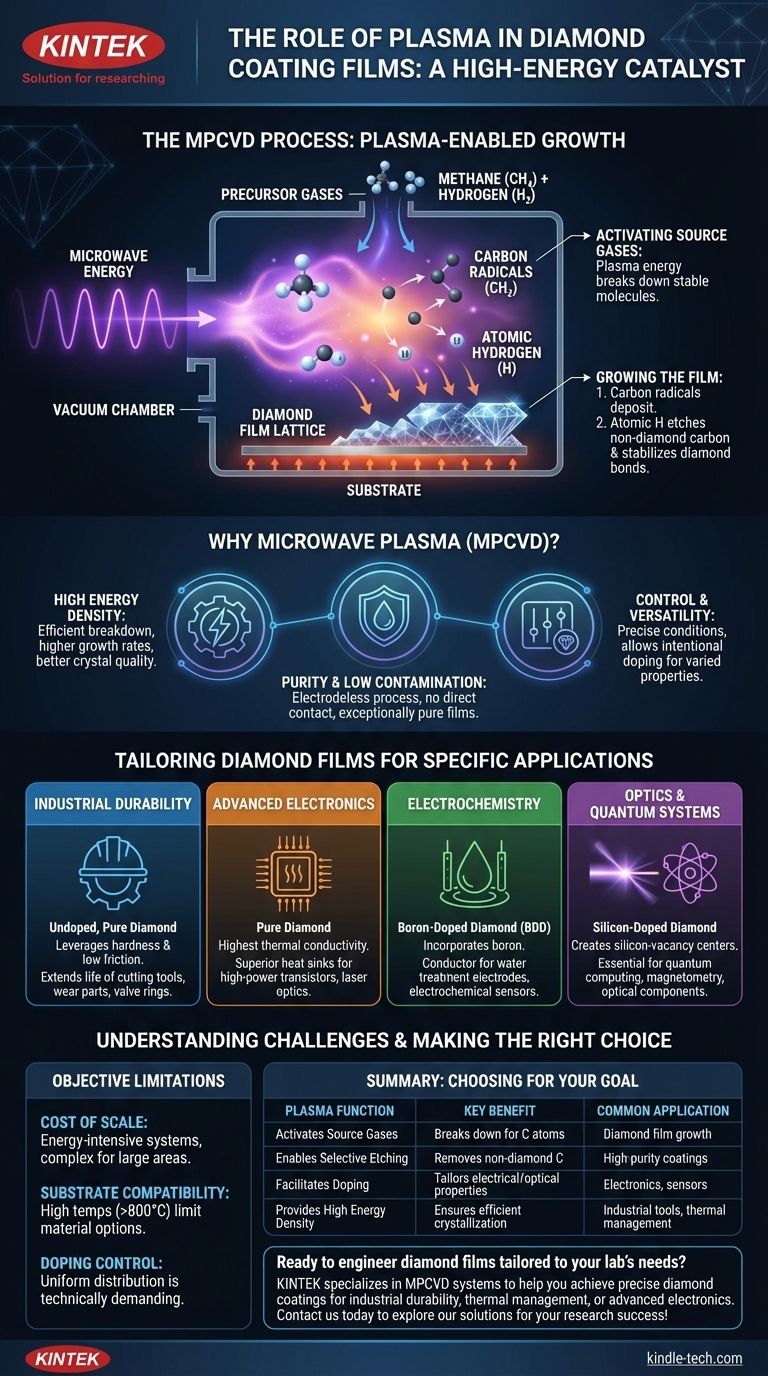

In the production of diamond films, plasma acts as a high-energy catalyst. The most common and effective method is Microwave Plasma Chemical Vapor Deposition (MPCVD), where plasma is used to break down source gases like methane and hydrogen. This process frees the carbon atoms necessary to grow a pure, high-quality diamond film layer by layer onto a substrate.

The core function of plasma in this process is to provide the intense, clean energy required to create the ideal chemical environment for diamond growth. It enables the precise control needed to produce everything from ultra-hard industrial coatings to specialized electronic and optical materials.

The Role of Plasma in Diamond Deposition

To understand how diamond coatings are made, we must first look at the underlying process: Chemical Vapor Deposition (CVD). Plasma is the key that unlocks this process for diamond.

What is Plasma Chemical Vapor Deposition (CVD)?

CVD is a technique where a solid material is deposited onto a surface from a gas. For diamond, this means we need to get carbon atoms out of a gas and arrange them into a diamond crystal structure.

The challenge is that source gases, like methane (CH₄), are very stable. The plasma provides the energy needed to break them apart.

Activating the Source Gases

In an MPCVD system, a mixture of gases—typically a small amount of methane in a large amount of hydrogen—is fed into a vacuum chamber. Microwaves are then used to energize this gas mixture until it becomes a ball of glowing plasma.

This high-energy plasma rips molecules apart, creating a highly reactive soup of carbon-based radicals (like CH₃) and, crucially, atomic hydrogen (H).

The Growth of the Diamond Film

The carbon radicals deposit onto a heated substrate placed within the plasma. At the same time, the atomic hydrogen performs two critical jobs:

- It selectively etches away non-diamond carbon. Any carbon that tries to form weaker bonds, like graphite, is immediately removed by the reactive hydrogen.

- It stabilizes the diamond bonds. This ensures that the carbon atoms arrange themselves into the strong tetrahedral lattice of a pure diamond crystal.

This continuous process of deposition and etching is what allows for the growth of a high-quality, continuous diamond film.

Why Microwave Plasma (MPCVD) is the Preferred Method

While other methods exist, MPCVD is favored for preparing high-quality diamond films for several distinct reasons.

High Energy Density

Microwave plasma is extremely energetic and dense. This allows for the efficient breakdown of the source gases, leading to higher growth rates and better crystal quality compared to less intense plasma methods.

Purity and Low Contamination

MPCVD is an "electrodeless" process, meaning the plasma is generated by microwaves without direct contact with any electrodes. This avoids a common source of contamination, resulting in exceptionally pure diamond films. This low-pollution nature is critical for high-performance applications.

Control and Versatility

The MPCVD process allows for precise control over the growth conditions. By introducing other gases into the plasma, we can intentionally "dope" the diamond to change its properties.

This versatility allows us to create diamond films tailored for specific tasks, turning a single material into a platform for diverse technologies.

Tailoring Diamond Films for Specific Applications

The ability to control the plasma process allows for the creation of different types of diamond films, each optimized for a unique purpose.

For Industrial Durability: Hardness and Low Wear

An undoped, pure diamond film leverages diamond's natural hardness and low friction. These films are grown on cutting tools, wear-resistant parts, and valve rings to dramatically extend their operational life.

For Advanced Electronics: Thermal Management

Diamond has the highest thermal conductivity of any known material. Pure diamond films are grown on heat-producing electronics, such as high-power transistors or laser optics, where they act as superior heat sinks to prevent overheating and failure.

For Electrochemistry: Boron-Doped Diamond (BDD)

By adding a boron-containing gas to the plasma, boron atoms are incorporated into the diamond lattice. This transforms the diamond from an electrical insulator into a conductor. BDD films are highly valued for advanced electrodes in water treatment and electrochemical sensing.

For Optical and Quantum Systems: Silicon-Doped Diamond

Similarly, adding a silicon-containing gas creates specific, light-emitting defects in the diamond known as "silicon-vacancy centers." These films are essential for emerging applications in quantum computing, highly sensitive magnetometry, and advanced optical components.

Understanding the Trade-offs and Challenges

While powerful, the plasma deposition of diamond is not without its limitations. Objectivity requires acknowledging these realities.

The Cost of Scale

MPCVD systems are complex and energy-intensive. While ideal for high-value components, economically coating very large areas—such as for consumer cookware—remains a significant engineering and cost challenge.

Substrate Compatibility

The diamond growth process requires high substrate temperatures, often exceeding 800°C. The material being coated must be able to withstand these conditions without warping or degrading, which limits the range of compatible substrates.

Doping Concentration Control

The final properties of a doped diamond film depend heavily on the concentration of the dopant. Achieving a perfectly uniform dopant distribution across an entire film is technically demanding and requires extremely precise control over the plasma chemistry.

Making the Right Choice for Your Goal

The optimal diamond film is defined entirely by the problem you need to solve. Your application dictates the necessary properties.

- If your primary focus is mechanical durability: An undoped, pure diamond film grown via MPCVD offers the best hardness and wear resistance for tools and protective coatings.

- If your primary focus is thermal management: A high-purity, thick diamond film is ideal for efficiently drawing heat away from sensitive electronic components.

- If your primary focus is electrochemistry: A boron-doped diamond (BDD) film provides the necessary conductivity for applications like water treatment or advanced sensors.

- If your primary focus is optics or quantum sensing: A silicon-doped film is required to create the specific vacancy centers that enable these advanced functionalities.

By leveraging plasma to control the growth process at an atomic level, we can engineer diamond films with precisely the properties needed to solve a vast range of technical challenges.

Summary Table:

| Plasma Function | Key Benefit | Common Application |

|---|---|---|

| Activates Source Gases | Breaks down methane/hydrogen for carbon atoms | Diamond film growth |

| Enables Selective Etching | Removes non-diamond carbon for purity | High-purity coatings |

| Facilitates Doping | Tailors electrical/optical properties (e.g., boron, silicon) | Electronics, sensors |

| Provides High Energy Density | Ensures efficient, rapid diamond crystallization | Industrial tools, thermal management |

Ready to engineer diamond films tailored to your lab’s needs? KINTEK specializes in lab equipment and consumables, including MPCVD systems, to help you achieve precise diamond coatings for industrial durability, thermal management, or advanced electronics. Contact us today to explore how our solutions can enhance your research and application success!

Visual Guide

Related Products

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- CVD Diamond for Thermal Management Applications

People Also Ask

- How does chemical vapor deposition work for diamonds? Grow Lab-Created Diamonds Layer by Layer

- What is the process of MPCVD? Grow High-Purity Diamond & Advanced Films

- What is the step-by-step process for growing a diamond using the CVD method? Master Lab-Grown Diamond Synthesis

- What is deposition of diamond films? Grow High-Performance Diamond Coatings with CVD

- Why is MW-CVD preferred for high-purity diamond optical windows? Achieve Zero-Contamination Material Growth

- How does microwave induced plasma work? A Complete Guide to MIP Technology

- How long do lab-grown diamonds take to make? A 6-8 Week Journey from Seed to Gem

- What are the benefits of microwave plasma process? Achieve Faster, More Uniform Heating for Advanced Materials