To prevent mechanical damage to an all-PTFE electrolytic cell, you must handle it with a focus on its material softness. Unlike glass, which is hard but brittle, PTFE is a soft polymer susceptible to scratches, warping, and deformation. Avoid any impact with hard objects, do not over-tighten threaded components, and use only soft materials for cleaning to protect its critical sealing surfaces.

The core challenge is recognizing that PTFE's exceptional chemical resistance comes with mechanical vulnerability. The primary goal is not just to prevent outright breakage, but to protect the integrity of its soft surfaces and threads, which are essential for maintaining a hermetic seal and ensuring experimental reproducibility.

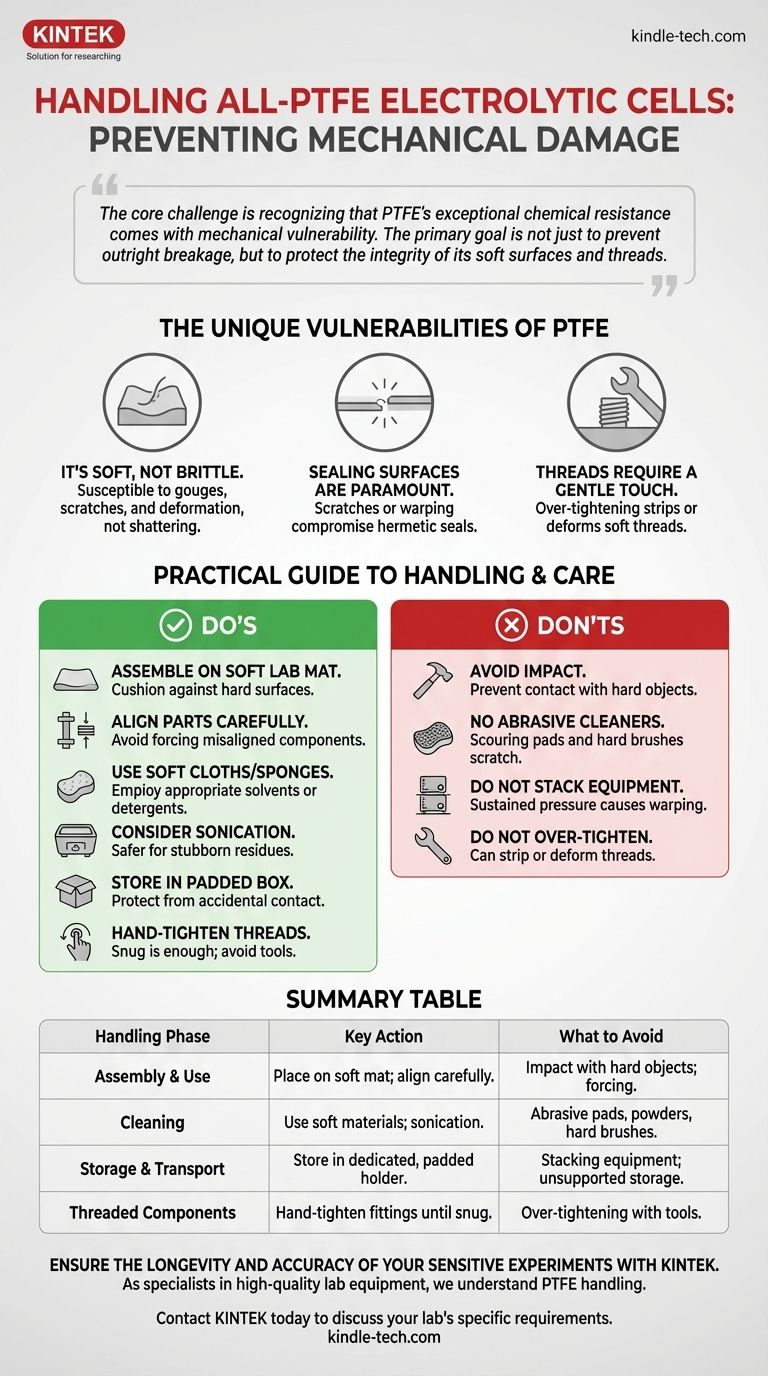

The Unique Vulnerabilities of PTFE

While valued for its chemical inertness, PTFE (Polytetrafluoroethylene) has mechanical properties that demand specific handling protocols. Understanding these properties is the key to preventing damage.

It's Soft, Not Brittle

PTFE will not shatter like glass, but it can be easily gouged, scratched, or deformed. Even a minor scratch from a metal tool can create a significant surface flaw.

These flaws can compromise your experiments by trapping contaminants that are difficult to clean or by becoming stress points that lead to cracking over time.

Sealing Surfaces are Paramount

Most electrolytic cells rely on a perfect seal between the cell body and the lid to maintain an inert atmosphere.

Any scratch or indentation on these flat sealing surfaces can create a leak path. A deformed or warped cell body or lid, often caused by impact or improper storage, will fail to seal correctly, rendering sensitive experiments invalid.

Threads Require a Gentle Touch

Many PTFE cells feature threaded ports for electrodes, tubing, or other components. These threads are part of the soft cell body.

Over-tightening fittings can easily strip or deform these threads, a type of damage known as "galling." Damaged threads will not seal properly and are often impossible to repair. Always hand-tighten fittings until they are just snug.

A Practical Guide to Handling and Care

Applying a few conscious habits during use, cleaning, and storage will dramatically extend the life and performance of your all-PTFE cell.

During Assembly and Use

Place the cell on a soft, non-slip lab mat to prevent it from sliding and to cushion it from the hard benchtop.

When inserting electrodes or probes, ensure they are perfectly aligned before applying gentle pressure. Forcing a misaligned component is a common cause of damage to ports.

During Cleaning

Never use abrasive scouring pads, powders, or hard-bristled brushes. These will permanently scratch the PTFE surfaces.

Use soft, lint-free cloths or sponges with appropriate solvents or detergents. For stubborn residues, sonication is often a safer and more effective option than mechanical scraping.

During Storage and Transport

Store the cell in a dedicated, padded box or a foam holder. This protects it from accidental contact with heavier or sharper lab equipment.

Never stack other equipment on top of the cell or its components, as the sustained pressure can cause warping over time.

Making the Right Choice for Your Goal

Adopting the right handling protocol is about safeguarding both your investment and your data.

- If your primary focus is experimental reproducibility: Be obsessive about protecting the flat sealing surfaces on the cell body and lid, as this is critical for a consistent, hermetic seal.

- If your primary focus is equipment longevity: Implement a strict protocol of hand-tightening all threaded components and using only soft materials for cleaning.

- If you are training new personnel: Emphasize that PTFE's key weakness is its softness, a direct contrast to the brittle nature of the glassware they are likely more familiar with.

Proper handling ensures your all-PTFE cell will remain a reliable tool for producing high-quality, trustworthy data for years to come.

Summary Table:

| Handling Phase | Key Action | What to Avoid |

|---|---|---|

| Assembly & Use | Place on a soft lab mat; align components carefully. | Impact with hard objects; forcing misaligned parts. |

| Cleaning | Use soft cloths/sponges and sonication for residues. | Abrasive pads, powders, or hard-bristled brushes. |

| Storage & Transport | Store in a dedicated, padded box or foam holder. | Stacking equipment on top; unsupported storage. |

| Threaded Components | Hand-tighten fittings until just snug. | Over-tightening with tools. |

Ensure the longevity and accuracy of your sensitive experiments with KINTEK.

As specialists in high-quality lab equipment, we understand that the superior chemical resistance of PTFE requires specific handling care to maintain its mechanical integrity. Protecting your investment in specialized apparatus like all-PTFE electrolytic cells is crucial for reproducible results and data integrity.

Let our experts help you select the right equipment and establish best-practice protocols for your laboratory. We provide the reliable tools and consumables you need to work with confidence.

Contact KINTEK today to discuss your lab's specific requirements and discover how our solutions can support your research goals.

Visual Guide

Related Products

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

People Also Ask

- What is the precaution regarding temperature when using an all-PTFE electrolytic cell? Essential Thermal Safety Tips

- What precautions should be taken during the storage of an all-PTFE electrolytic cell? Prevent Permanent Deformation and Seal Failure

- How should an all-PTFE electrolytic cell be cleaned before use? Expert Protocol for Pure Electrochemical Results

- What are the standard opening specifications for all-PTFE electrolytic cells? A Guide to Sealed vs. Non-Sealed Ports

- What materials are used for the body of a super-sealed electrolytic cell and what are their properties? Select the Right Material for Your Experiment